Monolith separation medium for chromatography and process for producing the same

a technology of chromatography and monoliths, applied in other chemical processes, instruments, transportation and packaging, etc., can solve the problems of low uniformity of structure, particle aggregation type, and low performance of monoliths based on silica gel, and achieve high performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Reagents and Solvent

[0033]Used were 2,2,2-tri-(2,3-epoxypropyl)-isocyanurate (TEPIC-S), which is an optically active SSS-isomer, as epoxy compound, bis(4-aminocyclohexyl)methane (BALM) as an amine compound, and polyethylene glycol having a molecular weight of 200 (PEG200, a commercial name of Nacalai Tesque, Inc.) as a porogen.

[0034]The chemical structure formulas of TEPIC and BACM are shown below.

[Production of Polymer Monolith]

[0035]Following addition of 0.37 g of BACM and 7.00 g of PEG200 to 1.6 g of TEPIC-S, they were heated and stirred with a hot stirrer into a state where they are dissolved. Thereafter, they were filled into a fused quartz capillary tube and heated for 20 hours in a drier at 80° C. to be polymerized.

[0036]Then, the resultant was washed with water and methanol, and then dried in vacuo.

Production Conditions

[0037]

TEPIC-S1.6gBACM0.37gPEG2007.00gTemperature80°C.

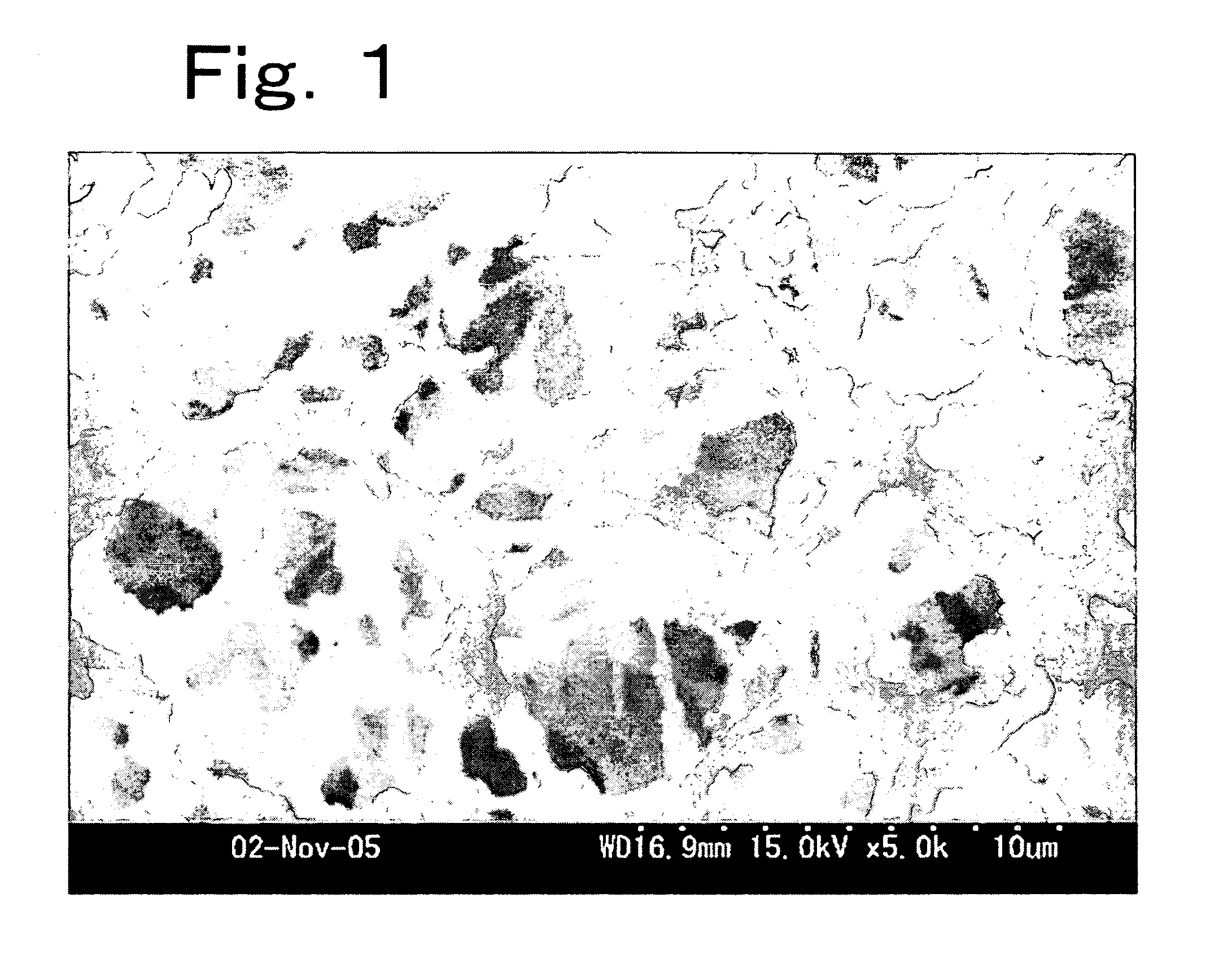

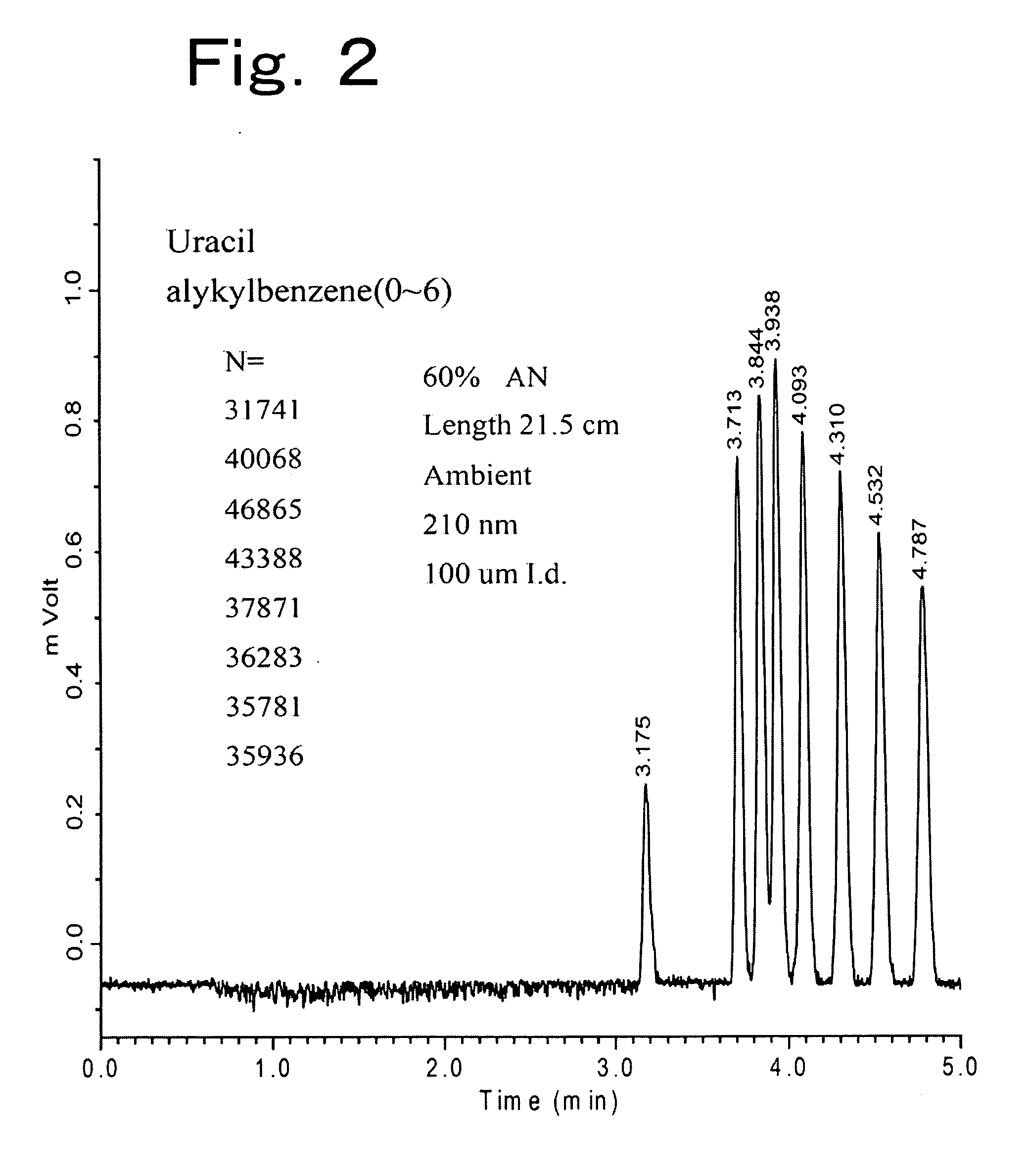

[0038]A scanning electron micrograph of the organic polymer monolith capillary column produced by the abo...

example 2

[0043]By using optically active substances as both an epoxy compound and an amine compound, a chiral organic polymer monolith capillary column was produced.

[0044]An optically active SSS-isomer of 2,2,2-tri-(2,3-epoxypropyl)-isocyanurate (TEPIC-S) in an amount of 0.40 g as an epoxy compound, 0.63 g of an optically active isomer, (1S,2S)-(+)-1,2-cyclohexanediamine, and 10 g of polyethylene glycol having a molecular weight 300 (PEG300) were mixed, heated and stirred into a state where they were dissolved. Thereafter, they were filled into a fused quartz capillary tube, and heated for 4 hours in an oven at 120° C. to be polymerized.

[0045]Then, the resultant was washed with water and methanol, and then dried in vacuo.

Production Conditions

[0046]

TEPIC-S0.40g(1S,2S)-(+)-1,2-cyclohexanediamine0.63gPEG30012.64gTemperature120°C.

[0047]The organic polymer monolith of Example 2 produced by the above-mentioned polymerization was also a skeletal phase similar to that of the example 1.

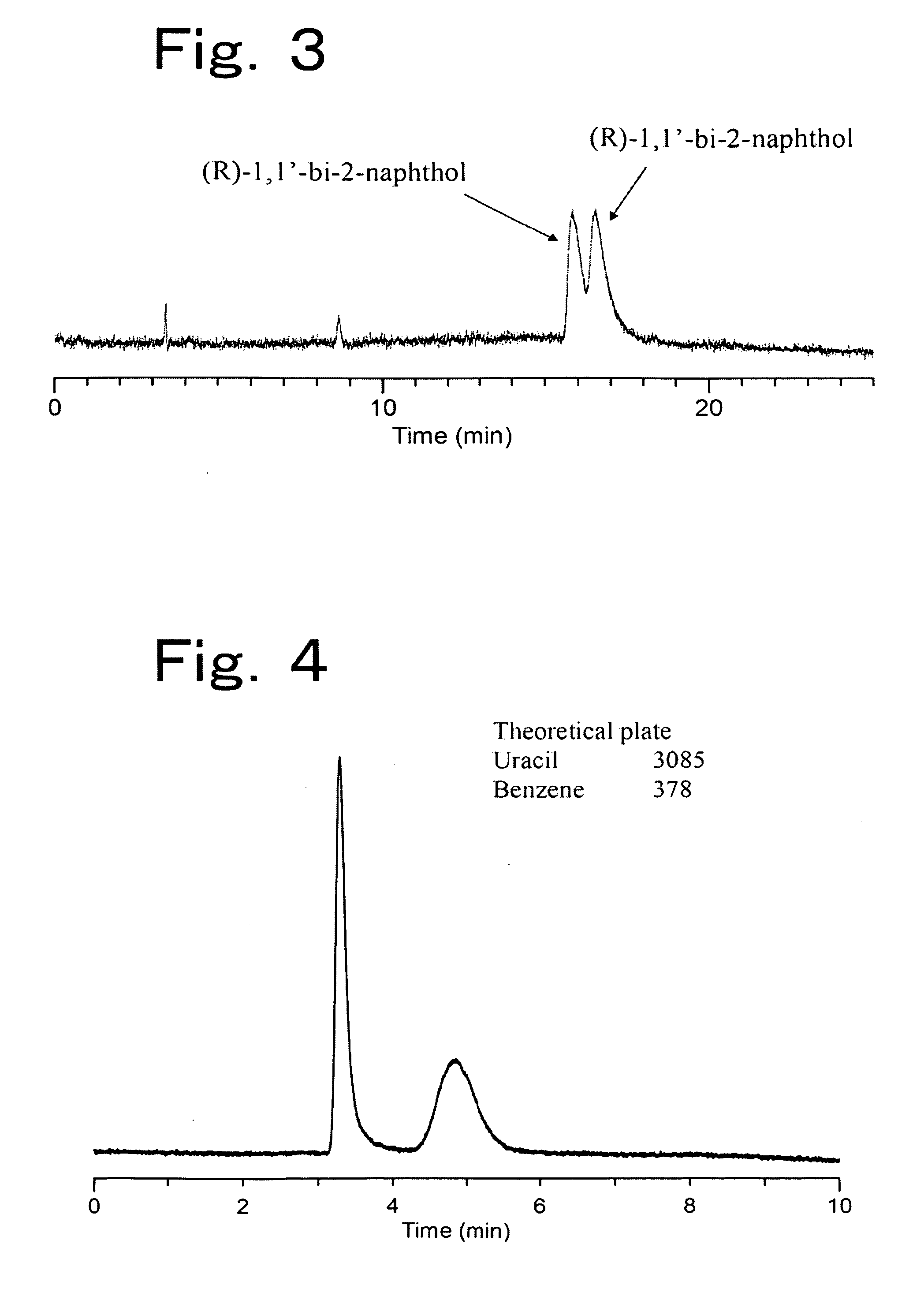

[0048]A separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Electrical conductance | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com