Method for preparing polymer grade low-carbon olefin through separation of methanol pyrolysis gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

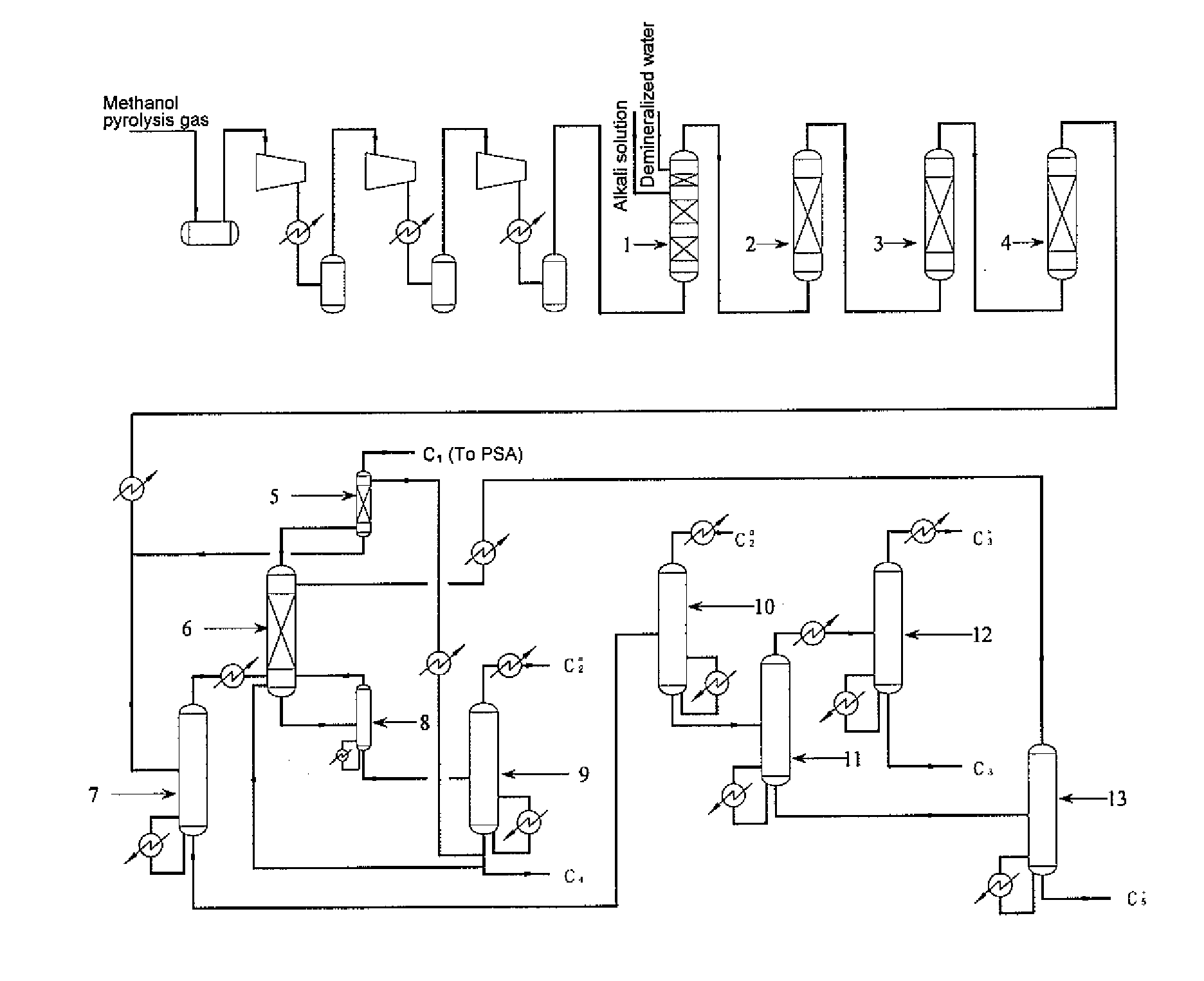

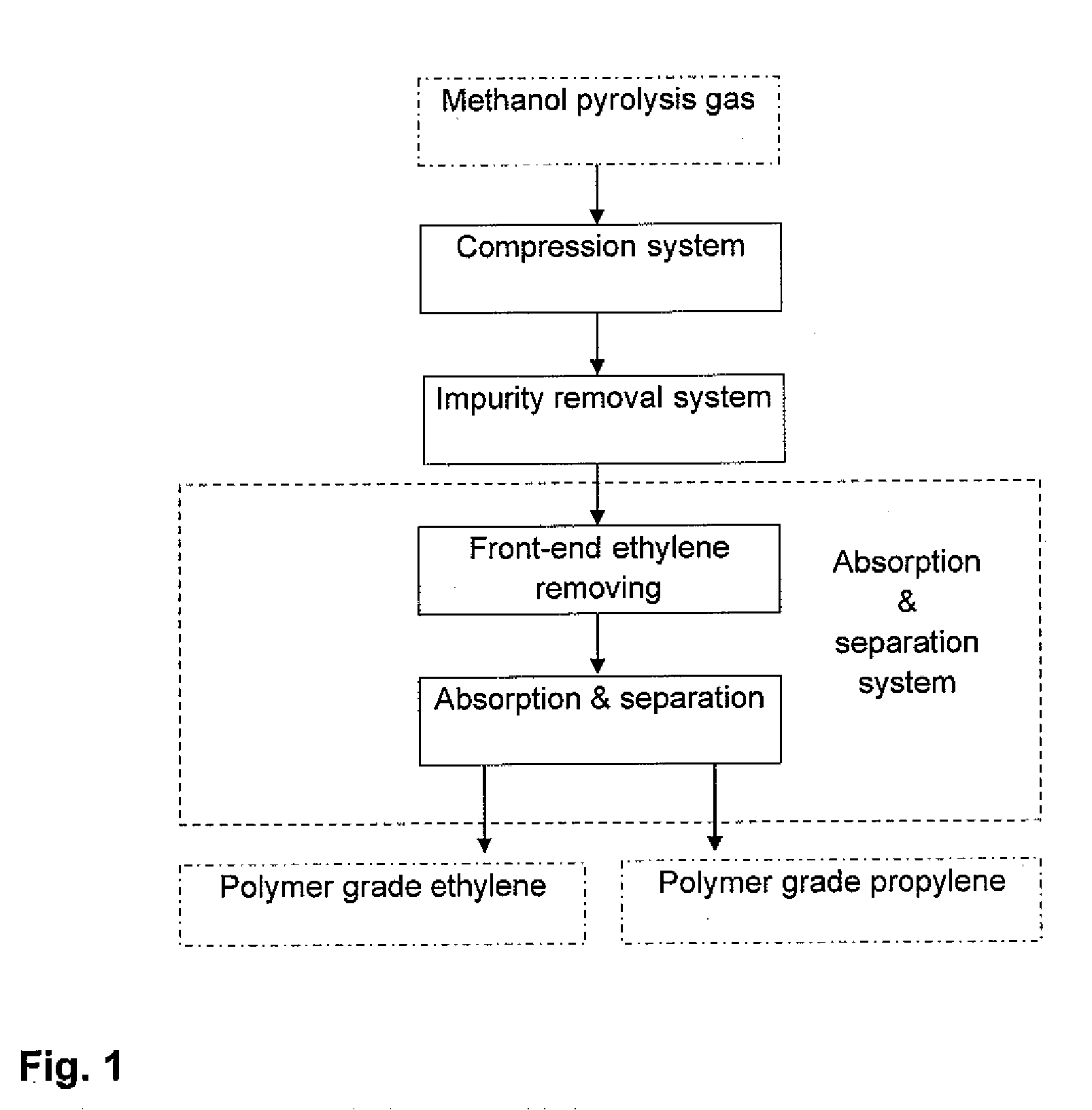

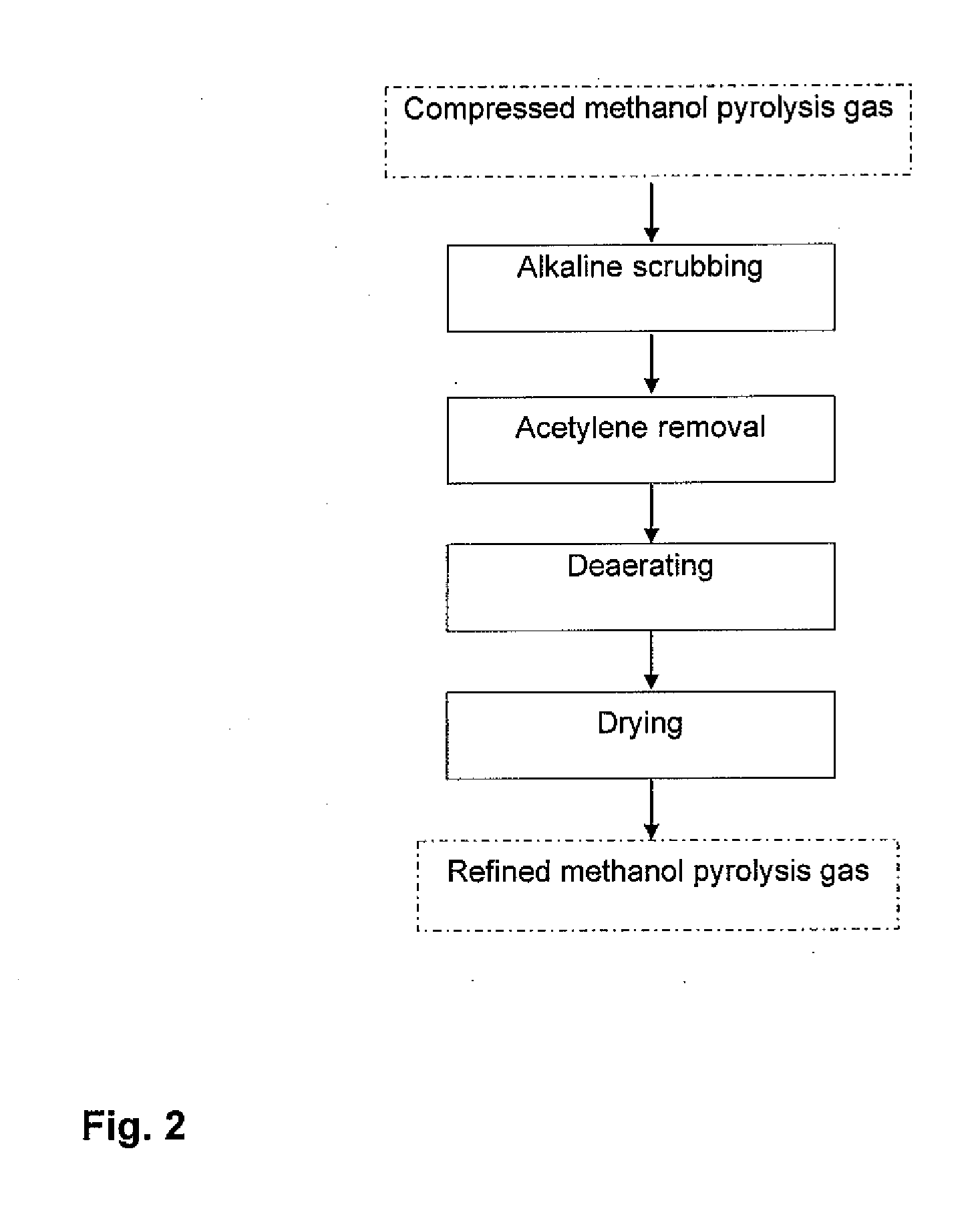

[0047]The methanol pyrolysis gas is subject to the 3- to 4-stage compression up to 1.1-2.5 MPaG and then sent into the impurity removal system. The compressed methanol pyrolysis gas enters the alkaline scrubbing column to remove the acidic substances such as CO2 using the NaOH water solution, or depending on the conditions of the raw materials, additionally using the amine washing process. Then, the pyrolysis gas enters in turn the acetylene remover, deaerator and drying column to remove impurities such as the alkyne, oxygen and water. Finally, the refined pyrolysis gas goes into the absorption and separation system.

[0048]The refined pyrolysis gas is cooled with the propylene refrigerant in the pyrolysis gas cooler, and then enters the front-end ethylene removing column, which uses hot water as the reboiler's heat source. For the gas in the upper portion of the front-end ethylene removing column, the −60 to −40° C. ethylene refrigerant is used for cooling. In the upper portion of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com