Semiconductor device including metal silicide layer and method for manufacturing the same

a technology of metal silicide layer and semiconductor device, which is applied in the direction of semiconductor device, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of difficult, if not impossible, to properly deposit refractory metal, and insufficient thickness of refractory metal layer, so as to reduce manufacturing time and cost, reduce manufacturing steps, and increase manufacturing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

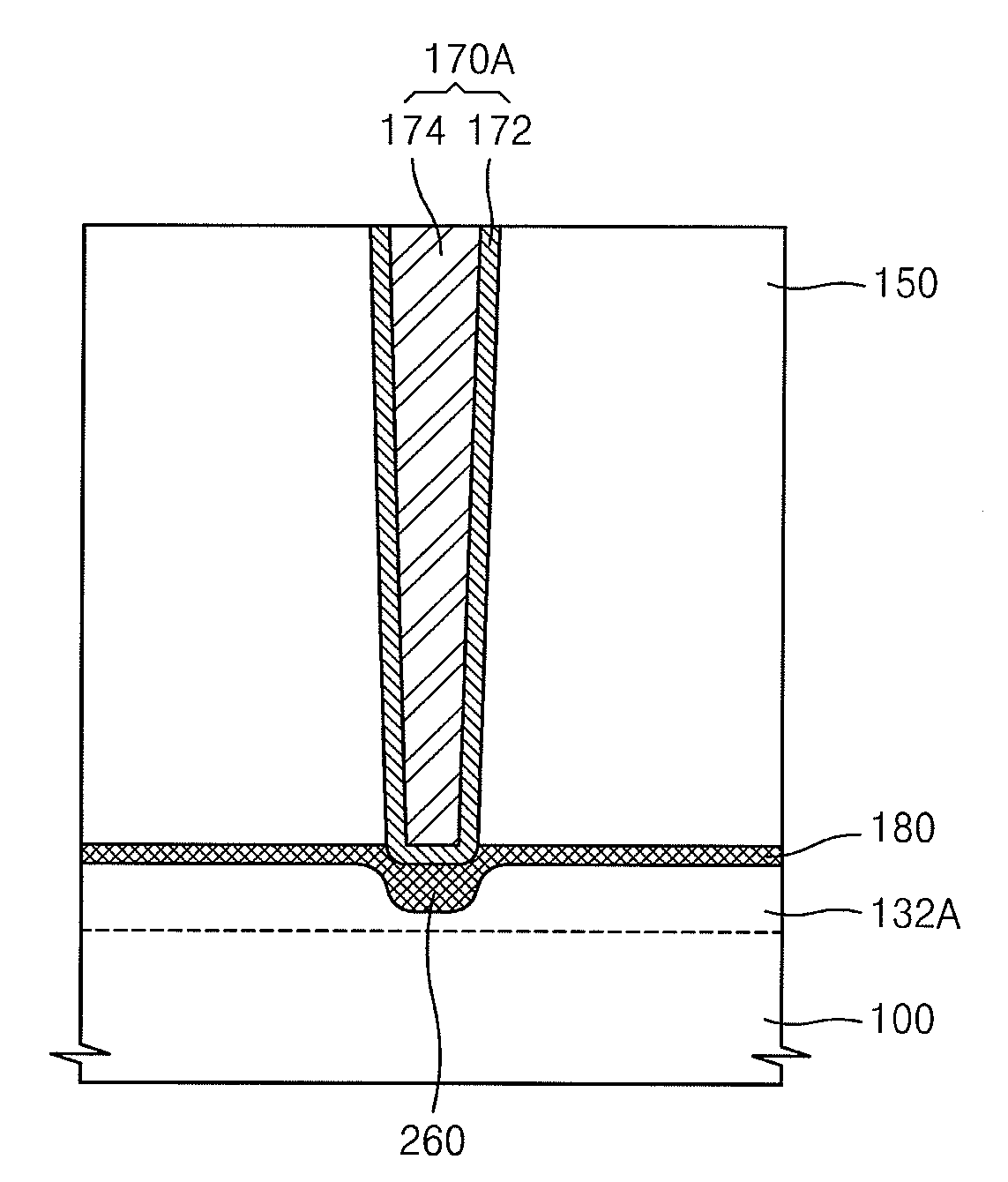

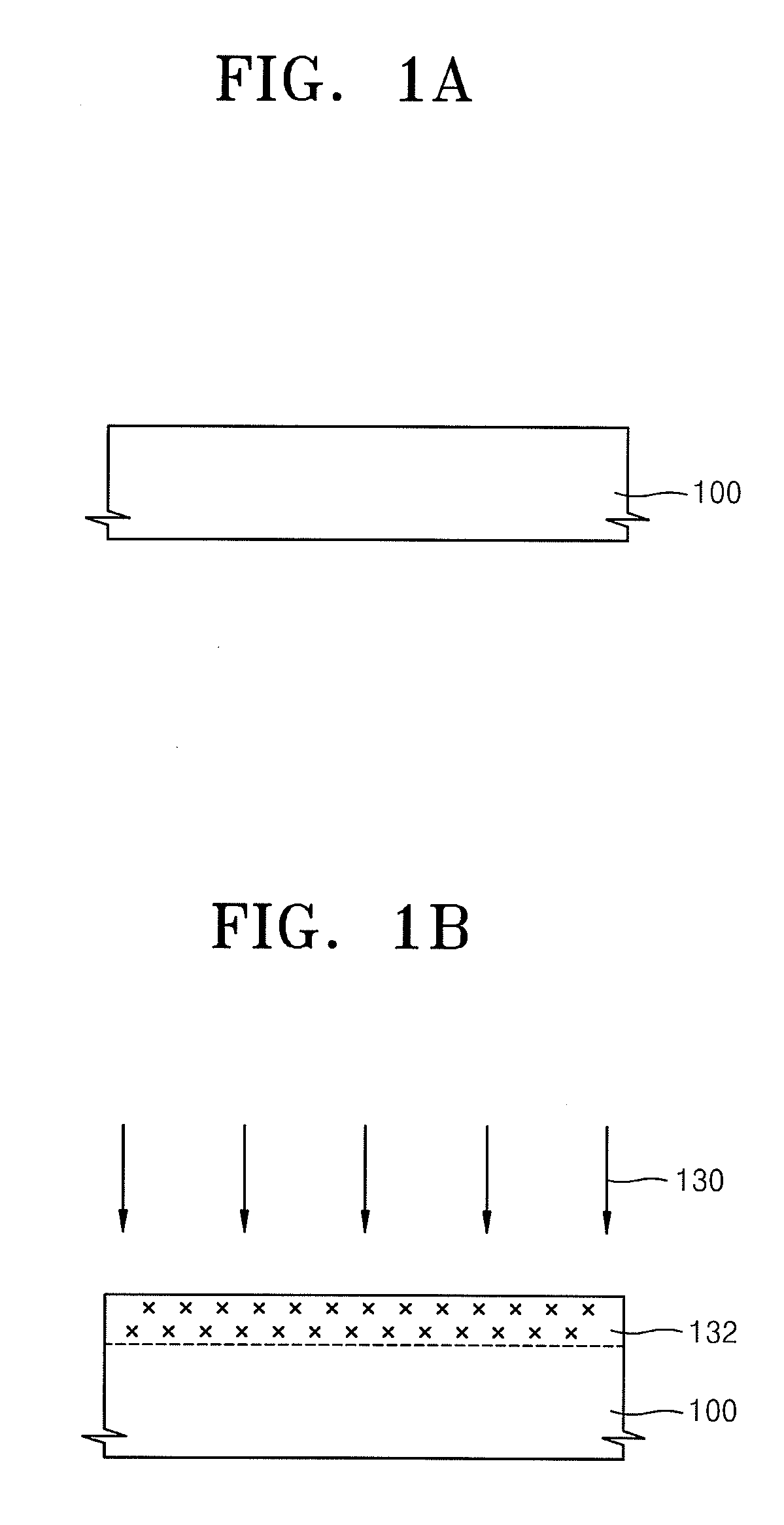

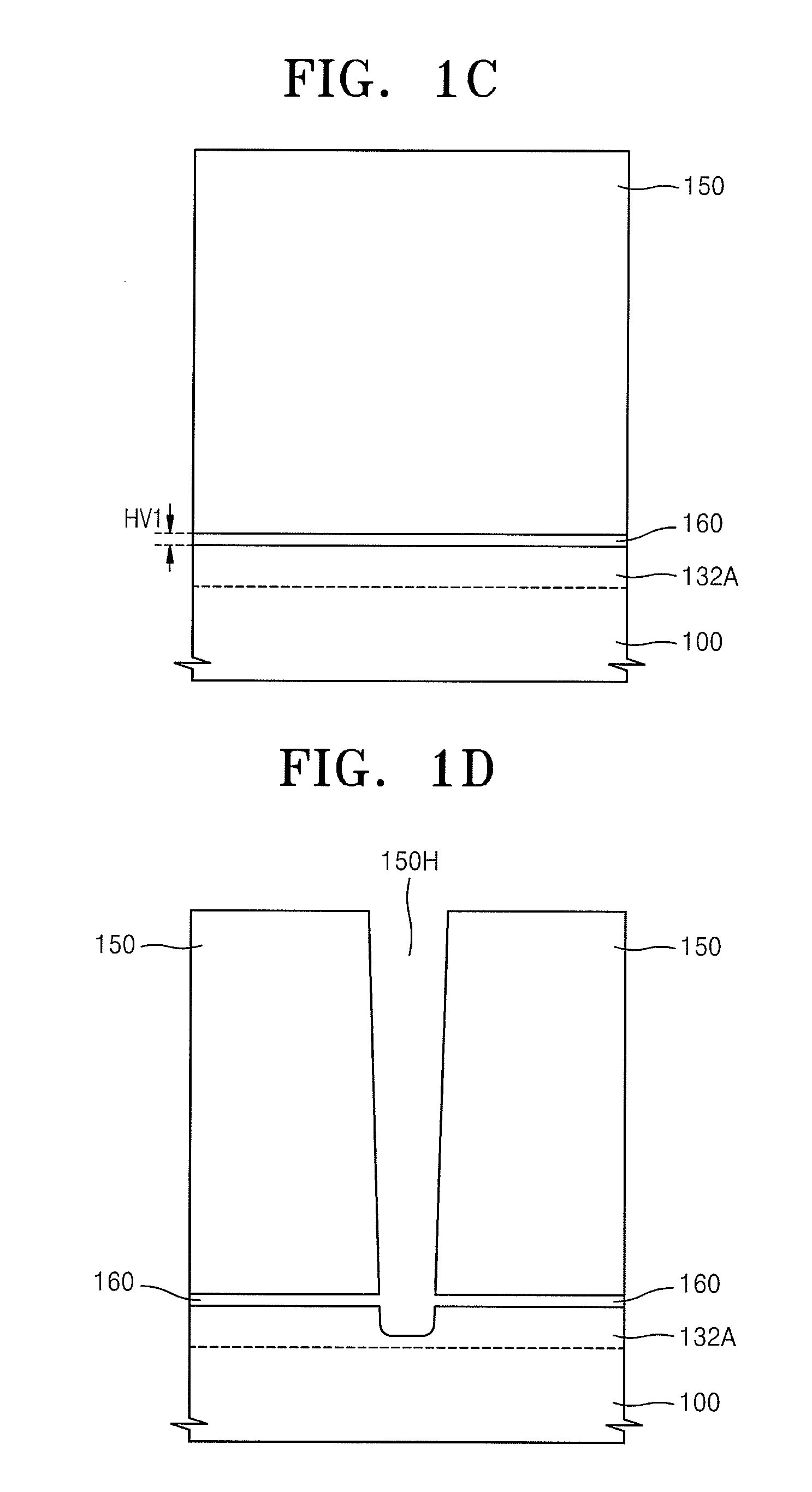

[0050]FIGS. 1a to 1f are cross sectional views showing a fabrication method of a semiconductor device including a metal silicide layer 180 and conductive plug 170A, according to a first exemplary embodiment of the inventive concept.

[0051]Referring to FIG. 1a, a silicon substrate 100, for example, a conventional single crystal silicon substrate of a first conduction type, is provided. In alternative embodiments, a semiconductor substrate 100 may be an epitaxial growth silicon layer formed on a non-semiconductor substrate (e.g., silicon on insulator, SOI). The first conduction type may be a p-type or n-type. For convenience of illustration, this disclosure illustrates an example process of using a p-type semiconductor substrate 100. Device isolation (e.g., trench isolation, e.g., shallow trench isolation, STI, e.g., 1010 shown in FIG. 15c) are formed buried in the silicon substrate 100 to define at least one active region in the semiconductor substrate 100. In various embodiments of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com