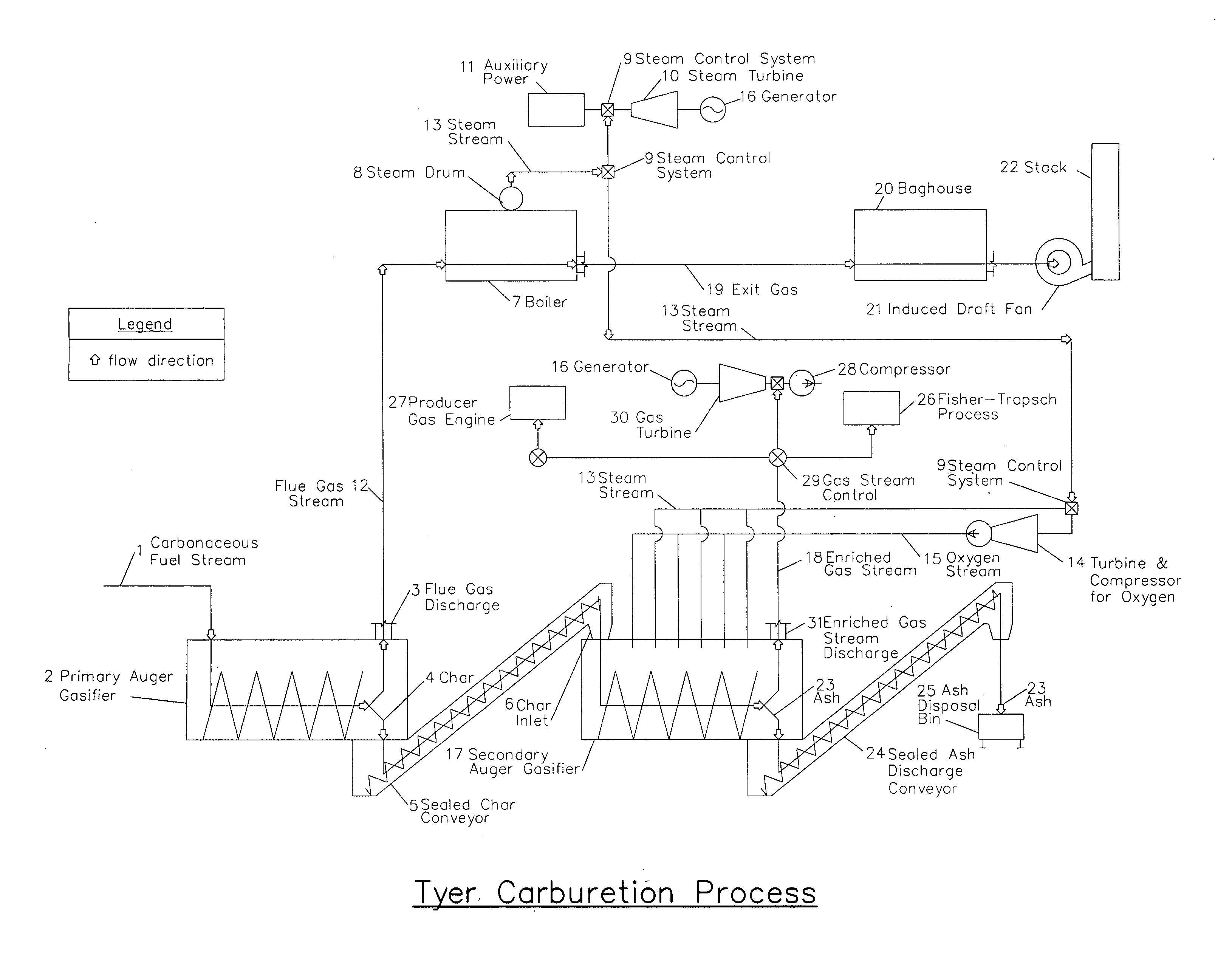

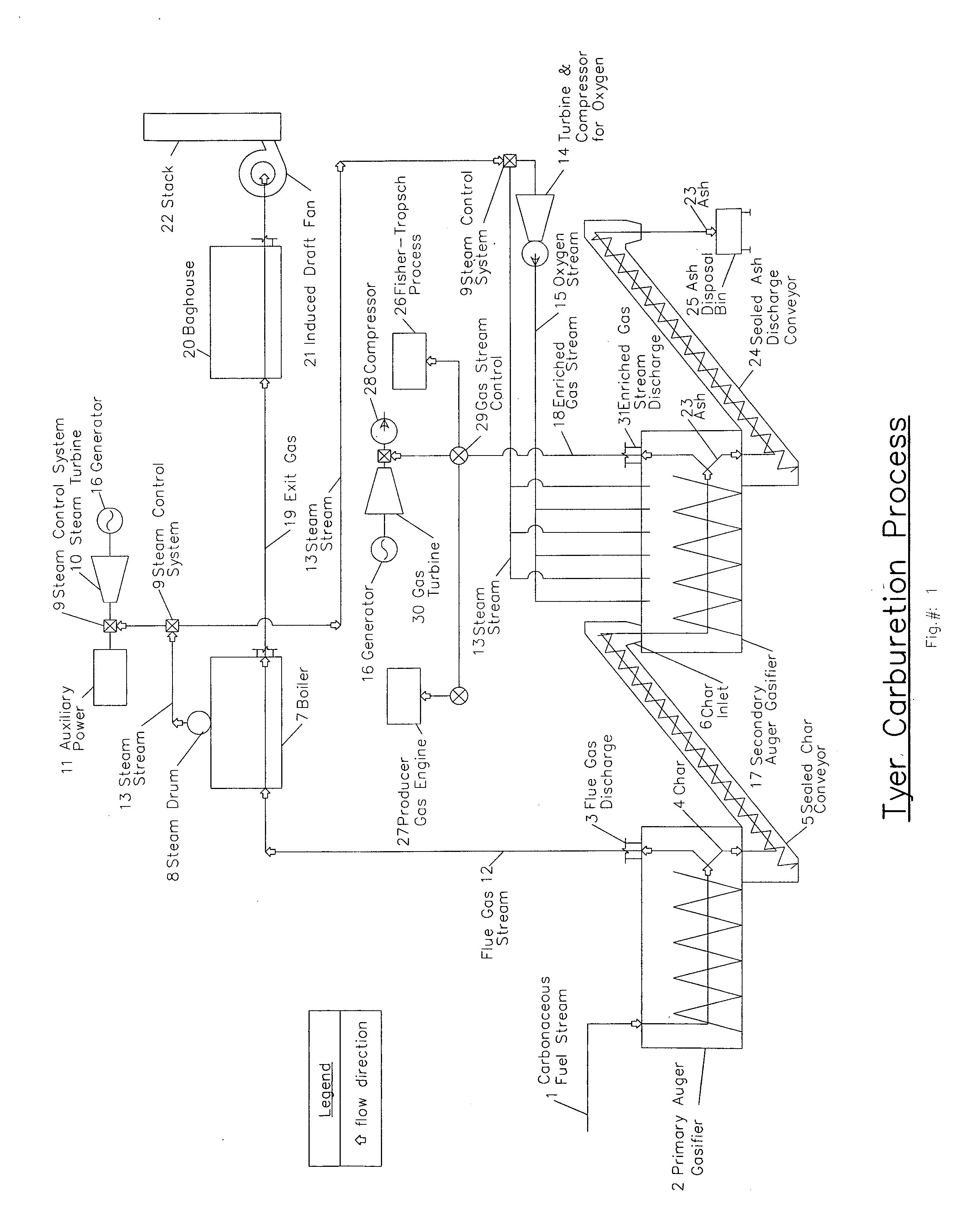

[0009]One of the unique features within the Tyer Carburetion Process

auger gasifier

system is its auger. Fuel enters the primary auger gasifier at a continuous controlled rate and is shaped into a

pile by the first auger flight, then pushed and tumbled through the gasifier chamber by the auger. As the auger moves the fuel through this horizontal gasifier cylinder, it stirs the material to maximize

exposure for oxidation and / or gasification; this is accomplished by reversing the direction the auger is traveling and creating a void between the auger flight and the gasifying fuel then reversing the direction again thus exerting force of the

char and pushing it into the un-gasified fuel. The

pitch of the auger can decrease, along the path of

material flow to accommodate the decrease of fuel bulk and

retention time as the material gasifies. The use of an auger to convey fuel through the gasification cycle is an improvement, which results in very accurately controlled movement of fuel through the gasification chamber, in comparison to alternative

rotary kiln incinerators. This ability to manage fuel-

bed configuration permits control of forced-draft

combustion air so as to minimize

combustion and gasify nearly all the carbonaceous fuel without complete

combustion taking place, thereby allowing the gasifier to operate at what is a uniformly

moderate temperature from auto-ignition to desired exit gas temperature, as well as, supplying

char and / or steam to the secondary auger gasifier.

[0010]The combination of fuel

bed auger agitating, stirring with air injection produce precise

temperature control evidencing the Tyer Carburetion Process auger gasifier

system several advantages over prior technology: Reliability and clean operation; high

throughput; low gasifier temperature, longer material life (

refractory and auger);

fully automatic control; and the ability to combust a wide variety of heterogeneous

solid fuels. However, several of these advantages are further strengthened by the addition of a substrate of appropriate granular materials to act as an “

air bearing” in the auger

combustor / gasifier chamber, and to aid in the

diffusion of gasification air through the material being burned as more fully described in U.S. Pat. No. 6,349,658.

[0011]Still, while the auger combustor / gasifier described in the foregoing patents offers a cost-effective approach to clean, efficient gasification, I have found that various innovative improvements, as further taught herein, support and facilitate its operations and efficiency. These improvements include provision of a vertically elongated (“oblong”) primary combustor / gasifier chamber with an auger that can move up and down allowing for large amounts of fuel input when necessary. This improvement, in turn, requires and / or is facilitated by provision for simultaneous elevation adjustments of the auger and

bed dam to assure that fuel material is processed in degrees from the top downward without sweeping massive amounts of the fluidized bed materials towards the output end of the chamber.

[0012]Another improvement involves provision for optional independent pressurization of the primary auger gasifier and / or of the secondary auger gasifier, allowing substantial increase in the fuel

processing speed through the gasifier. Because the Tyer Carburetion Process utilizes low gasification temperatures, high

convection rates and radiative

heat transfer, the heat, which is normally lost from the bulk bed material, is now providing to the fuel sufficient ignition energy to evaporate

moisture, heat the ash and gasify the remaining fuel without significantly changing the instantaneous bed temperature. My

Biomass bubbling bed operates sub-stoichiometrically, or below the

ideal gas laws because all the available

oxygen is used. If an increase of

oxygen was allowed into the auger gasifier chamber a greater portion of the fuel would become oxidize leading to an increase of the amount of bed heat that would be released; contrary to this, lower oxygen levels have the

reverse effect.

[0013]Because I can control both the duration and the direction of the auger cycles, use a lower gasification temperature, a higher

convection and

heat transfer rate, I can create a more efficient and cost effective

system which is well adapted to meet the continuing needs of our modern technological civilization for

elimination of waste, such as but not limited too,

RDF & MSW while producing clean environmentally

sound sources of

alternative energy therefrom. In addition to the aforementioned improvements, I have provided a provision within the Tyer Carburetion Process that allows the

water gas shift reaction, first discovered by Felice Fontana in 1780, to take place. As the heated bed radiates heat into the

refractory embedded down-tubes, the heat is absorbed, preheats the down-tubes carrying the steam and oxygen. This steam and oxygen is injected into and through the particle bed as the incandescent

char is tumbling over bed. As the auger tumbles the char, as previously mentioned, the perimeter char falls down into the void created by the moving auger into the center of the bed and allows the hot oxygen & steam emitted from the down-tubes to mix with the incandescent fuel thus creating the suitable environment for Fontana's

water gas shift reaction to happen.

Login to View More

Login to View More