Solar powered method and system for sludge treatment

a solar energy and sludge technology, applied in the field of solar energy-powered sludge treatment systems, can solve problems such as world-wide problems, and achieve the effects of reliable and comprehensive, high throughput, and green energy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

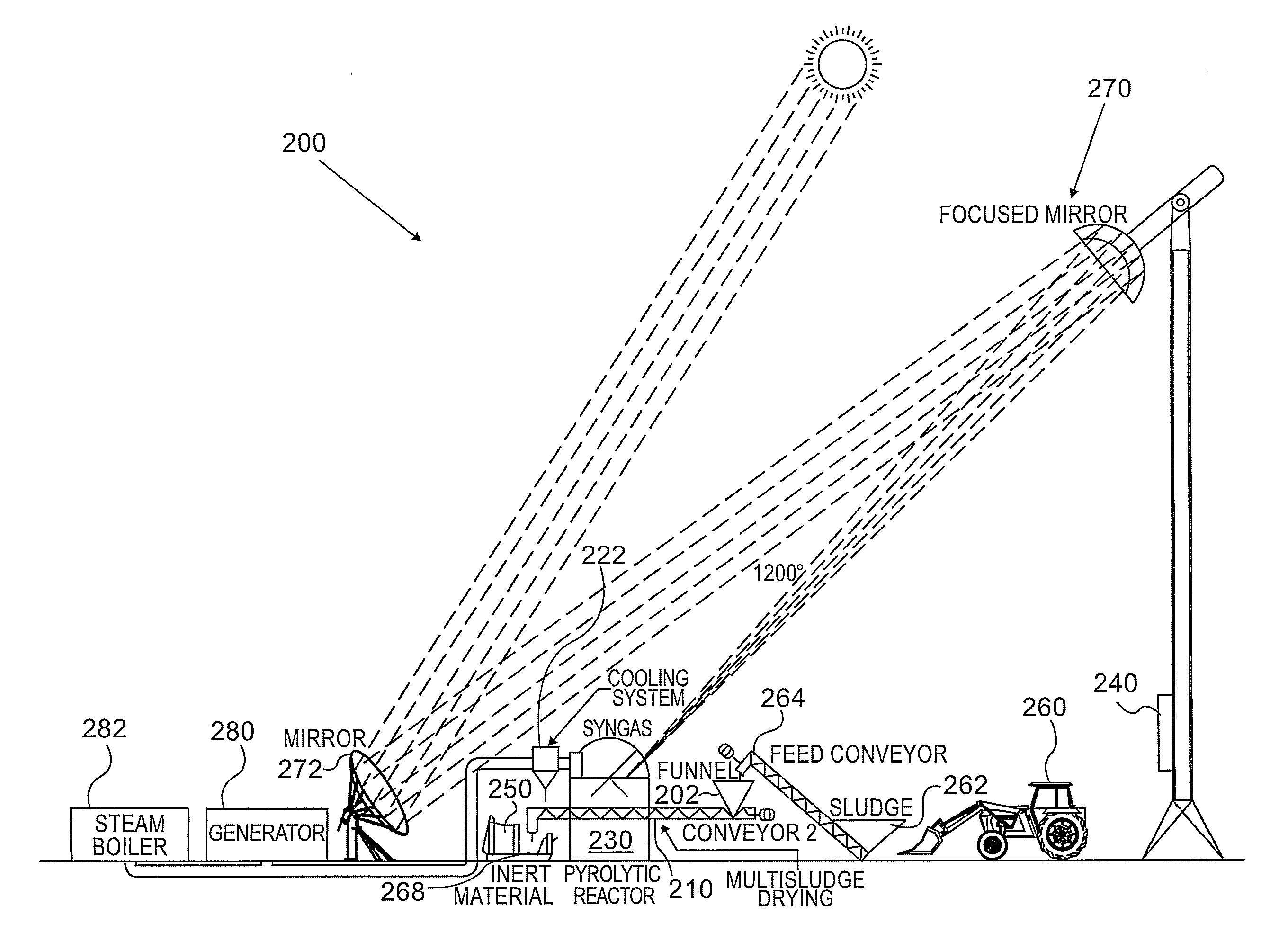

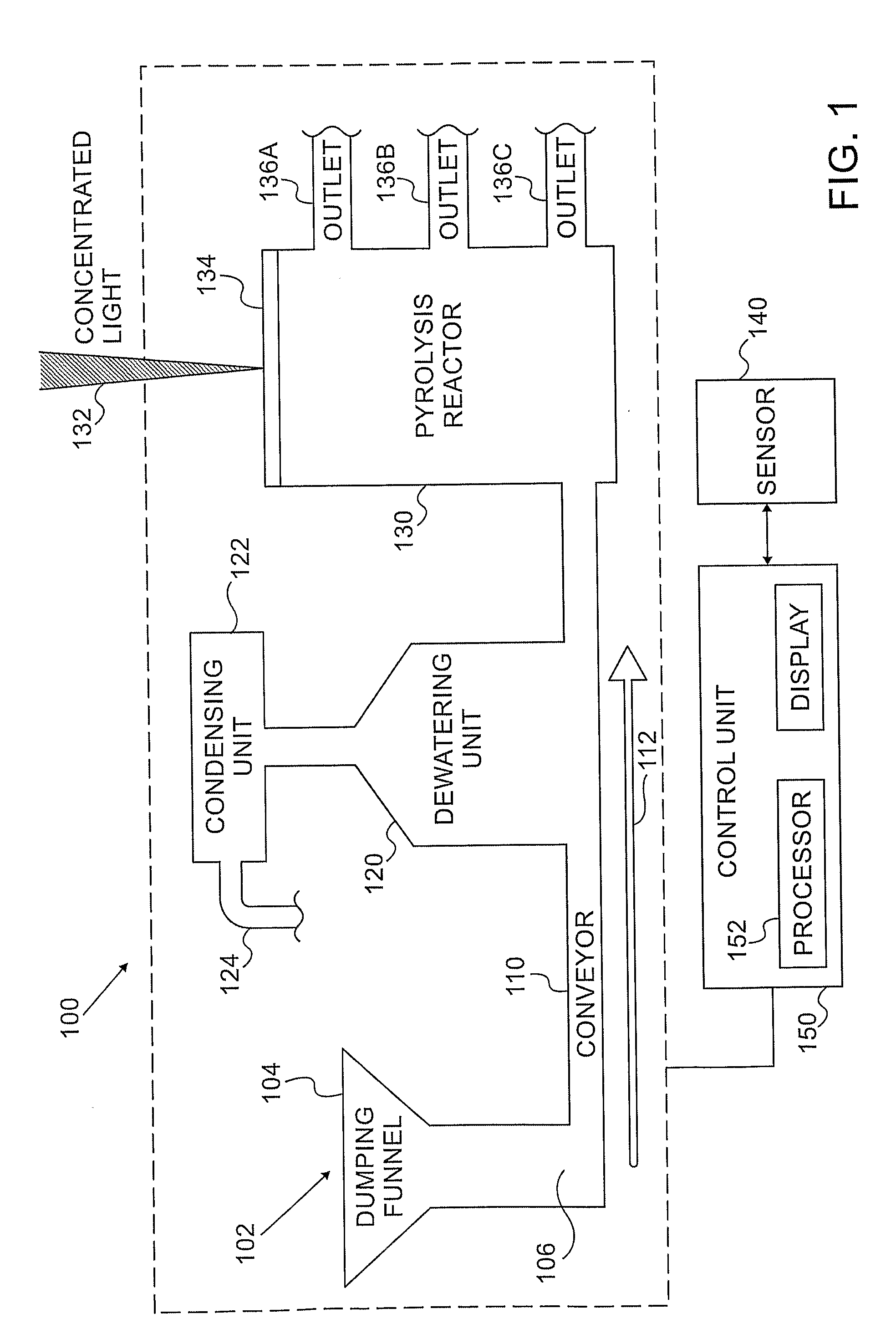

[0026]Reference is now made to FIG. 1 providing a schematic illustration of a sludge treatment system 100 in accordance with one embodiment of the invention. The sludge treatment system comprises a dumping funnel 102 for introducing sludge into the system. The dumping funnel has a top opening 104 for receiving the sludge and a bottom opening 106 for discharging the sludge onto a conveyor 110. While not illustrated in FIG. 1, the conveyor 110 may be adapted to remove an amount of liquid, typically water, from the sludge, to obtain a partially dewatered sludge comprising between 40-60% of initial weight. Typically, dewatering is carried out at temperatures of up to 400° C. yielding dewatered sludge ready for pyrolysis. Dewatering can be achieved, for example, by the use of a hot air blower or a spiral press conveyor. Liquid (typically water) removed from the sludge may be collected and directed for re-use (not illustrated). Conveyor 110 is connected dewatering unit 120 and is configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com