Silicate-free developer compositions

a developer composition and silicate-free technology, applied in the field of silicate-free and sugar-free alkaline developer compositions, can solve the problems of increasing the cost of imaging equipment, reducing the cleaning reducing the efficiency of processing equipment, so as to achieve the effect of inhibiting dissolution and simplifying the cleaning of processing equipmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

invention example 1

[0223]A sample of Precursor 1 was exposed using the Kodak® Magnus 400 Quantum imager at a range of energies, 50 mJ / cm2 to 200 mJ / cm2 and processed in a Mercury Mark VI processor using Developer 1 (shown below) at 23° C. for 20 seconds.

Developer 1ComponentConcentration %KOH2.70Potassium citrate1.75Bayhibit ® AM0.50CaCl2 × 2H2O0.04DowFax ® 2A10.50Hydromax 3000.10Water94.4

[0224]The results are shown in the following table.

Corrosion, WeightClearing PointLinearity Pointloss (Δm / S, g / m2)CDL %(mJ / cm2)(mJ / cm2)0.020.85090

[0225]Clearing Point is the lowest imaging energy at which the exposed regions were completely removed by the developer at a given temperature and time. Linearity Point is the energy at which the 50% dots at 200 lpi screen are reproduced as 50%±0.2% dots). Cyan Density Loss (CDL %) provides a measure of the resistance of the non-exposed regions on the lithographic printing plate to the developer. CDL % is calculated using the following formula.

CDL%=(ODb−ODa) / ODb×100

wherein O...

invention example 2

[0230]Invention Example 1 was repeated using samples of Precursor 2. The results obtained using fresh Developer 1 through an automatic processor are summarized in the following table.

Corrosion, WeightClearing PointLinearity Pointloss (Δm / S, g / m2)CDL %(mJ / cm2)(mJ / cm2)0.020.560100

[0231]In a loading test, a sample of Precursor 2 was imaged in the same way as in Invention Example 1 and was developed by hand using samples of Samples of Developer 1 that had been loaded with coating ingredients contained in the imageable layer of Precursor 1 in amounts corresponding to loading levels of 1.5 m2 / l, 3 m2 / l, 4.5 m2 / l, 6 m2 / l, and 9 m2 / l. The samples of Developer 1 were tested at 23° C. and 25 seconds dwell time. The following table shows the results of these tests.

Plate Loading Level(m2 / liter)CDL (%)Dot 50% (100 mJ / cm2)00.949.61.50.749.53.01.149.86.01.050.39.01.050.6

[0232]These results show that the image quality in terms of CDL and 50% dot readings using Precursor 2 is stable after Developer ...

invention example 3

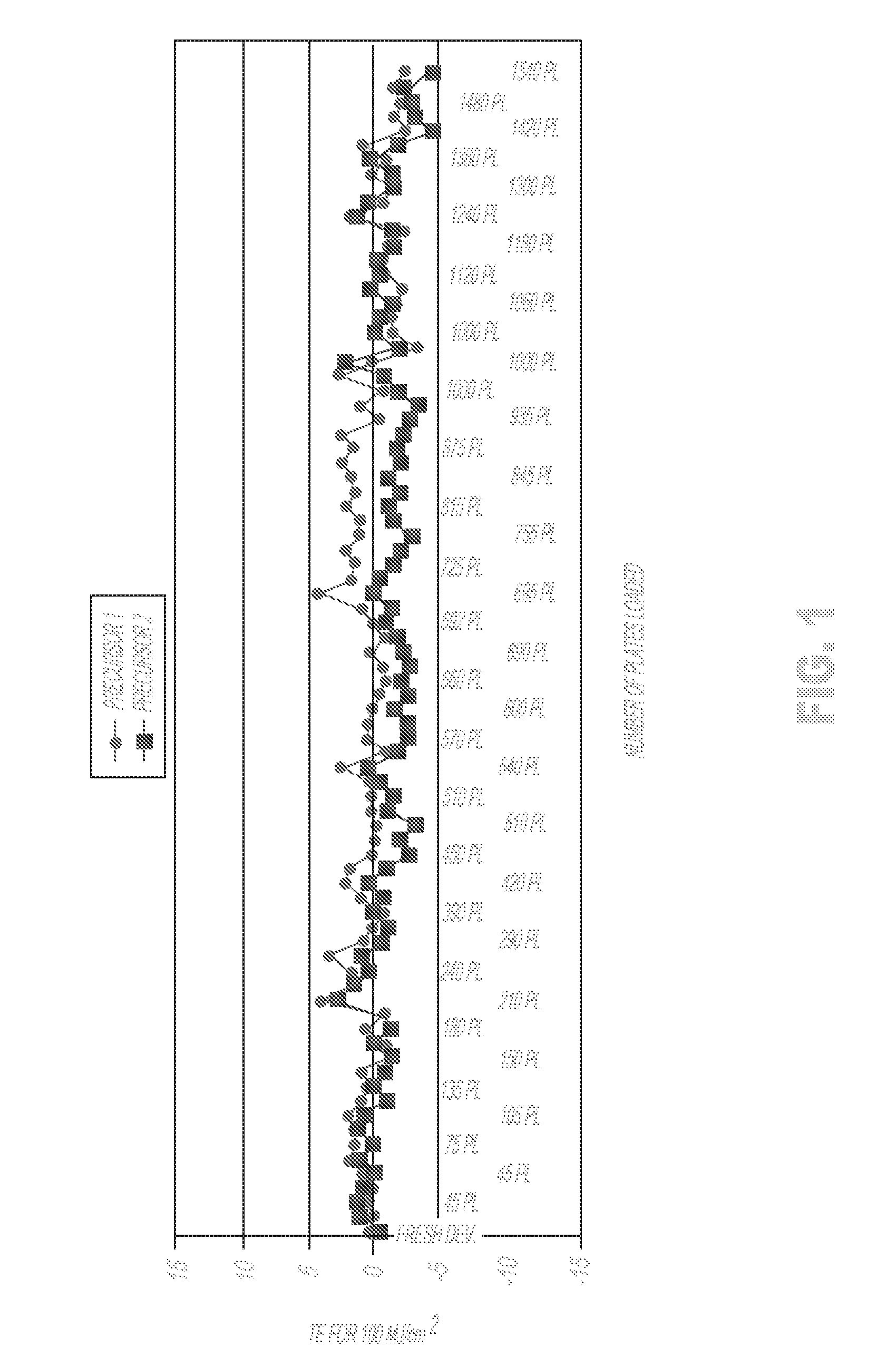

[0233]This example illustrates a process for maintaining the stability of Developer 1 in a Kodak Mercury Marc VI Processor during a loading cycle using 1030 cm×800 cm samples of Precursor 1 with its entire imageable layer imaged using a Kodak® Magnus 400 Quantum imaging device at 100 mJ / cm2 and using 1030 cm×800 cm samples of Precursors 1 and 2 imaged on the same imaging device with patterns containing areas representing 1% dots up to 99% dots at 200 LPI for image quality evaluation. The processor was set at a printing plate transport speed of 1500 mm / min (20 seconds dwell time) except that when test samples of Precursor 2 were processed, the transport speed was adjusted to 1700 mm / min (17 seconds dwell time). The developer tank temperature was set at 23° C. at all times and Developer 1 was replenished with Replenisher 1 at a rate of 40 ml / m2 of processed plates and 1 liter was added every 24 hours. The composition of Replenisher 1 is described in the following table.

Replenisher 1Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

| mol % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com