Method for improving the wear performance of ceramic-polyethylene or ceramic-ceramic articulation couples utilized in orthopaedic joint prostheses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

on of Biocompatible Silicon Nitride Ceramic Components

[0073]α-Si3N4 (90 wt. %), yttrium oxide (Y2O3, 6 wt. %), and aluminum oxide (Al2O3, 4 wt. %) raw powders were admixed in water, milled, and spray dried. The spray dried powders were then consolidated using uniaxial or isostatic compacting equipment (up to 310 MPa) to form appropriate shapes, i.e., femoral heads and mechanical test-bars. These components were subsequently machined to pre-fired dimensions using conventional computer-numerically-controlled (CNC) turning or milling machinery. They were then subjected to a series of heat-treatment operations including bisque firing, sintering, and hot-isostatic pressing at temperatures up to 1700° C. The firing steps eliminated carbonaceous compounds and water, reacted the constituent raw materials, and densified the ceramic to near-final size. Diamond grinding and polishing were then performed to achieve final size and surface finish for the components.

example 2

of Biocompatible Silicon Nitride Ceramic Components

[0074]The final components from Example 1 were subjected to hydrothermal oxidation using a steam autoclave at a pressure of 2 atm and a temperature of 121° C. for 24, 48, or 72 hours.

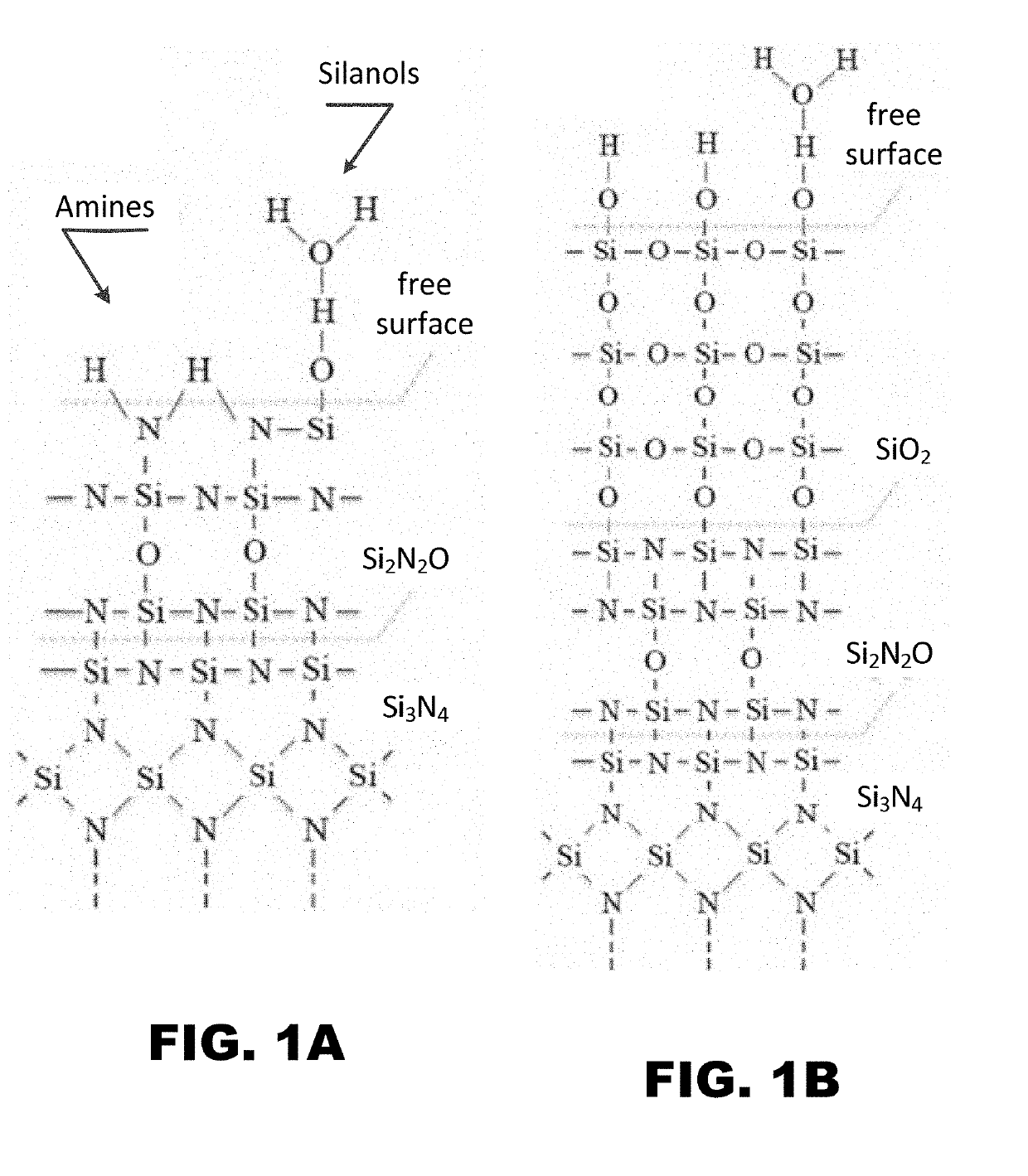

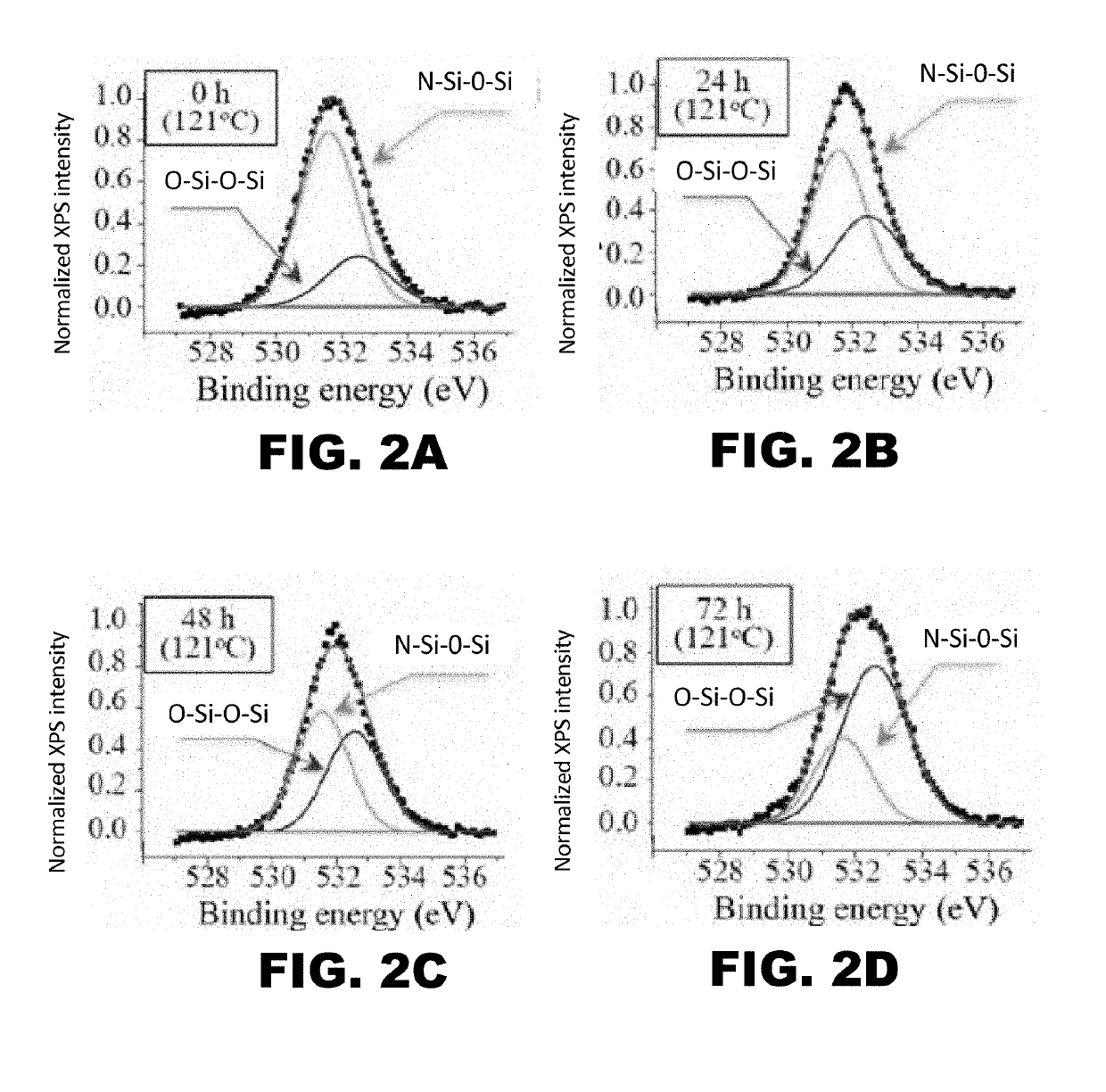

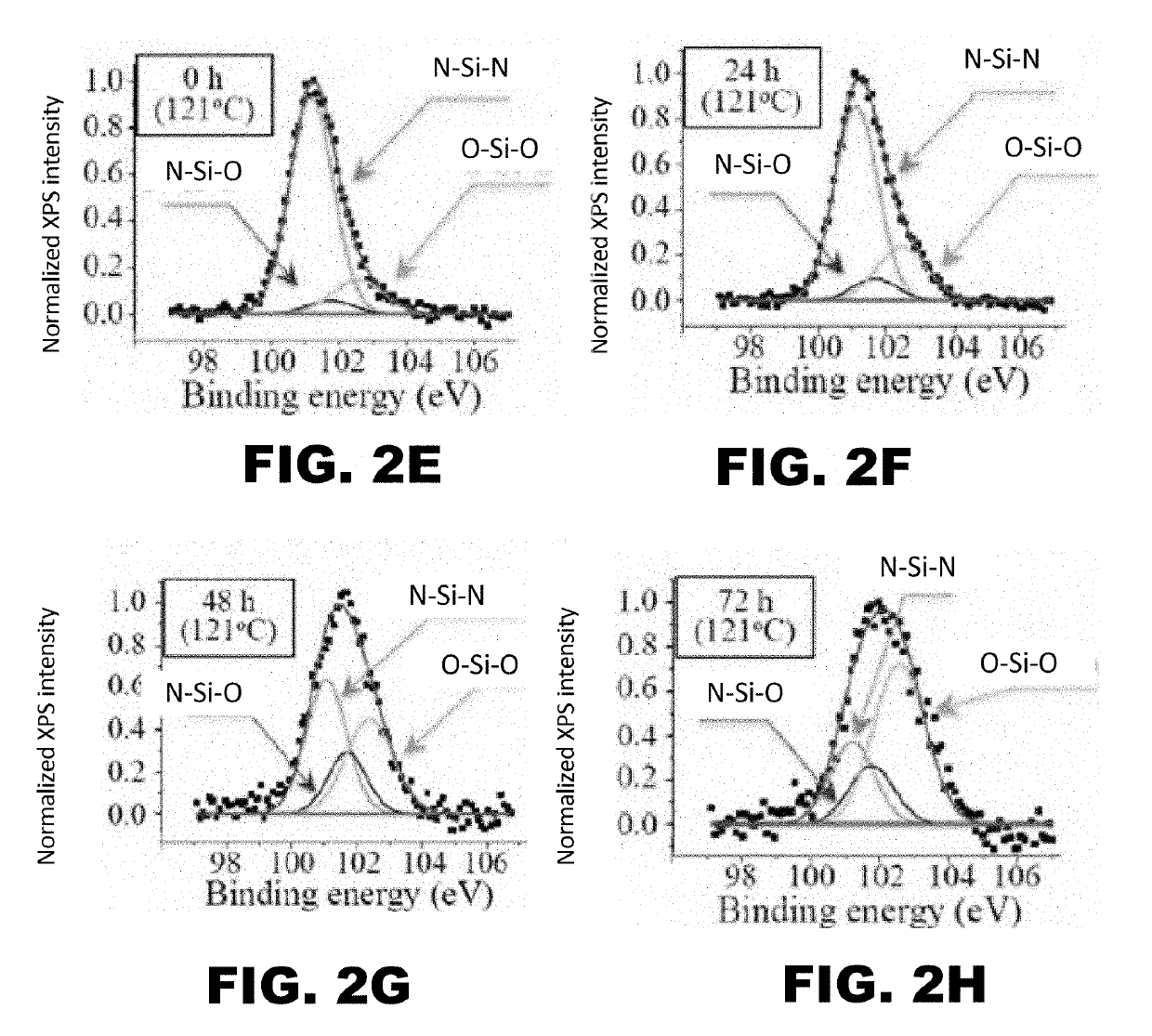

[0075]To determine the extent of the oxidation reaction, x-ray photoelectron spectroscopy was conducted on the oxidized components following 0 (FIG. 2A and FIG. 2E), 24 (FIG. 2B and FIG. 2F), 48 (FIG. 2C and FIG. 2G), and 72 (FIG. 2D and FIG. 2H) hours of exposure to the hydrothermal oxidation process. Further, the x-ray photoelectron spectroscopy analyzed the deconvolution of the O1s and Si2P bands. The results of the deconvolution of the O1s band (FIG. 2E, FIG. 2F, FIG. 2G, and FIG. 2H) demonstrated a reduction of near-surface N—Si—O—Si bonds in favor of O—Si—O—Si bonds. The results of the deconvolution of the Si2P band (FIG. 2E, FIG. 2F, FIG. 2G, and FIG. 2H) demonstrated a reduction of surface N—Si—N bonds in favor of N—Si—O and O—Si—O bonds. Both t...

example 3

ing

[0077]Femoral heads prepared as described in Examples 1 and 2 and femoral heads prepared with BIOLOX delta (zirconia-toughened alumina) were subjected to wear testing using a hip joint simulator. Specifically, the acetabular cups were subjected to hydrothermal oxidation treatment for 72 hours at 121° C. Briefly, the acetabular cups were weighted and pre-soaked in a bath comprising bovine serum to achieve a steady level of fluid sorption (as recommended in ISO 14242 / 2). After 50 hours of soaking, all acetabular cups were cleaned and re-weighted. This procedure was repeated until the incremental change of the acetabular cups over 24 hours was less than 10% of the previous cumulative mass change (as part ISO 14242—Part 2).

[0078]The acetabular cups were coupled to femoral heads and tested on a 12-station hip joint simulator using a lubricant (25% sterile calf serum (Sigma Aldrich, St. Louis, Mo.) balanced with deionized water, 0.2% sodium azide, and 20 mmol / dm3 ethylenediaminetetraac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com