Silica glass member for hermetic sealing of ultraviolet SMD LED element and method for manufacturing quartz glass member for ultraviolet LED

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

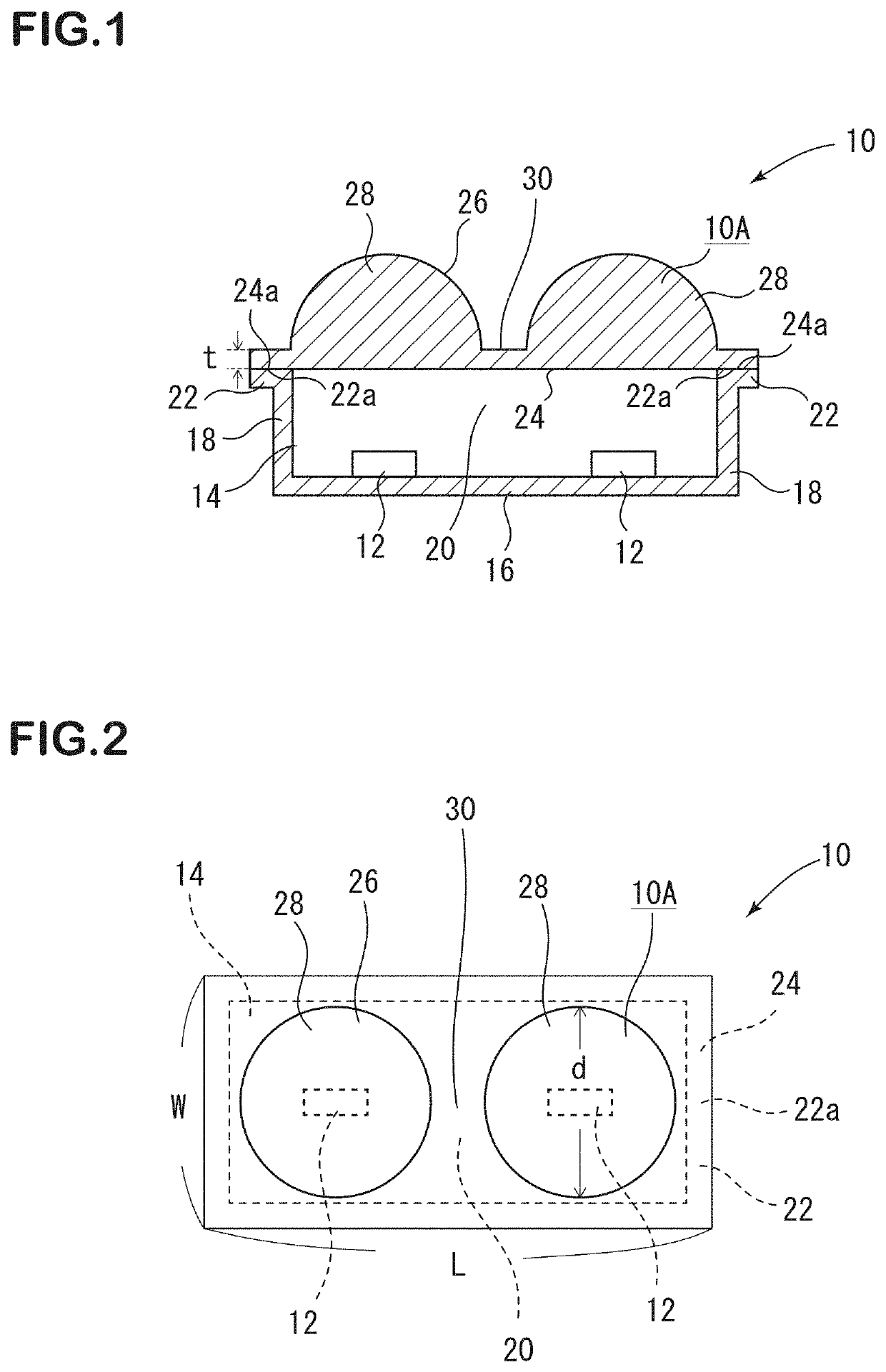

Image

Examples

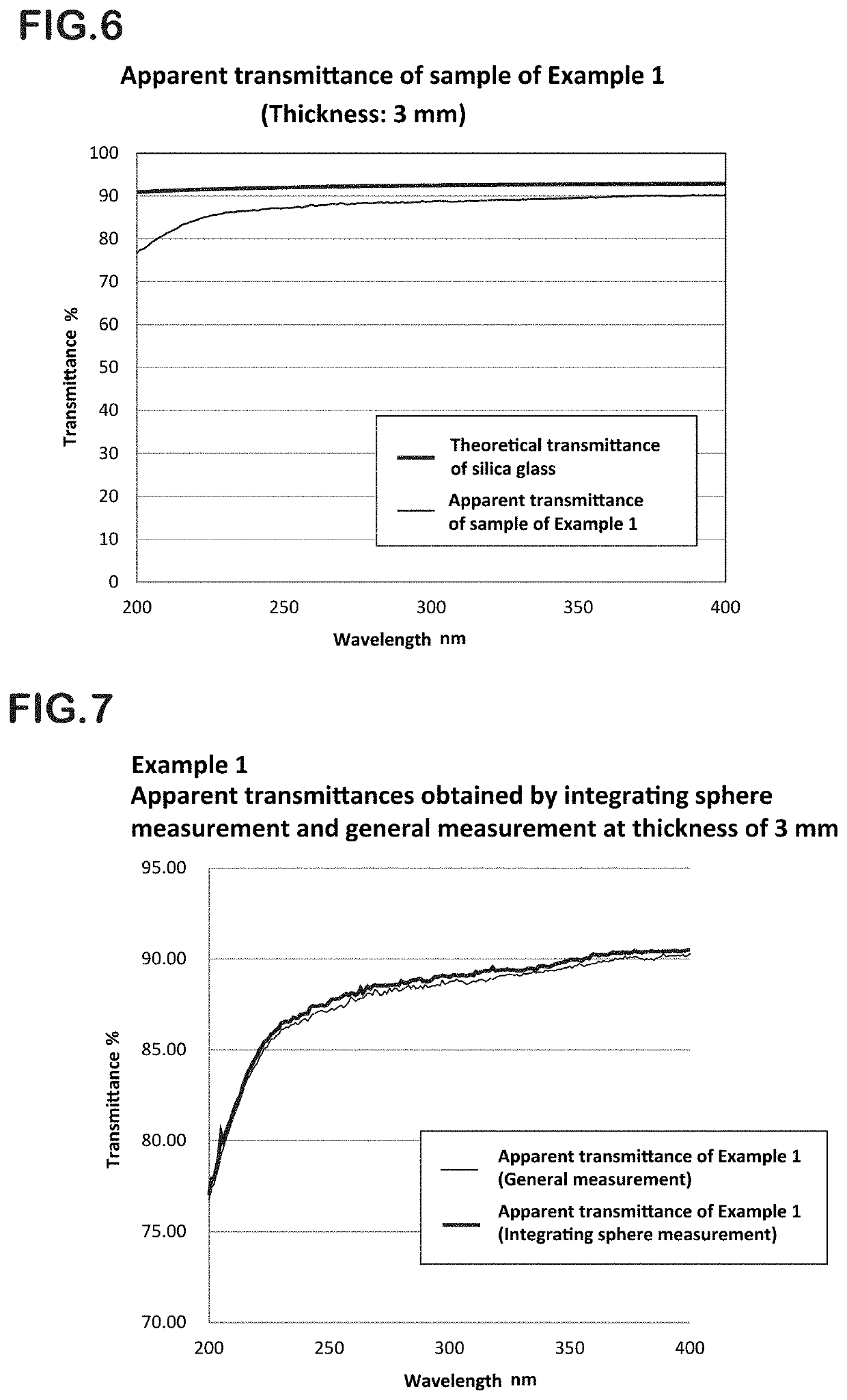

example 1

[0091](Formation of Plastic Matter)

[0092]79 Parts by weight of mixed powder obtained by mixing spherical synthetic silica powder having a diameter of 1.2 μm (product name: ADMAFINE SO-E3) and spherical synthetic silica powder having a diameter of 2 μm (product name: ADMAFINE SO-E5) at a weight ratio of 1:1, 20 parts by weight of an aqueous solution of 7.8 wt % METOLOSE (product name: SM-4000), and 1 part by weight of a lubricant (product name: UNILUBE 50 MB-2) were mixed and then kneaded with a triple roll mill to form plastic matter. The term “plastic matter” as used herein refers to a kneaded product of silica glass powder, in a state of having higher viscosity than a slurry, and having hardness and plasticity comparable to those of a clay.

[0093](Degassing Operation)

[0094]The formed plastic matter is degassed by being further kneaded under reduced pressure. Specifically, for example, kneading extrusion is performed using a kneading extrusion molding machine manufactured by Miyazak...

example 2

[0125](Molding Step)

[0126]79 Parts by weight of mixed powder obtained by mixing powder having an average particle diameter of 1.0 μm (ADMAFINE SO-E3 manufactured by Admatechs Company Limited) and powder having an average particle diameter of 2.0 μm (ADMAFINE SO-E5 manufactured by Admatechs Company Limited) at a weight ratio of 1:1, 20 parts by weight of an aqueous solution of 7.8% methylcellulose (METOLOSE SM-4000 manufactured by Shin-Etsu Chemical Co., Ltd.), and 1 part by weight of a lubricant (UNILUBE 50 MB-2 manufactured by NOF Corporation) were mixed and then kneaded with a triple roll mill. Through the use of a vacuum extrusion molding machine, the mixture was degassed, and subjected to kneading extrusion under a reduced pressure of 0.1 MPa.

[0127]The mixture of the silica powder and the binder subjected to the degassing treatment was injection-molded into a metal mold at an increased pressure of 120 MPa to provide a molded body having a predetermined shape. Here, with regard t...

example 3

[0148]A quartz glass member for an ultraviolet LED was obtained in the same manner as in Example 2 except that the treatment for repairing an oxygen-deficient defect was performed at a temperature of 1,050° C., and under an atmosphere containing water vapor produced by a method involving bubbling pure water kept at 30° C. with oxygen serving as a carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com