Grating coupled vertical cavity optoelectronic devices

a vertical cavity optoelectronic and grating technology, applied in the direction of lasers, lasers, semiconductor lasers, etc., can solve the problems of large waveguide loss, limitation of modulation bandwidth, and inability to realize optical sources with those modulation bandwidths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

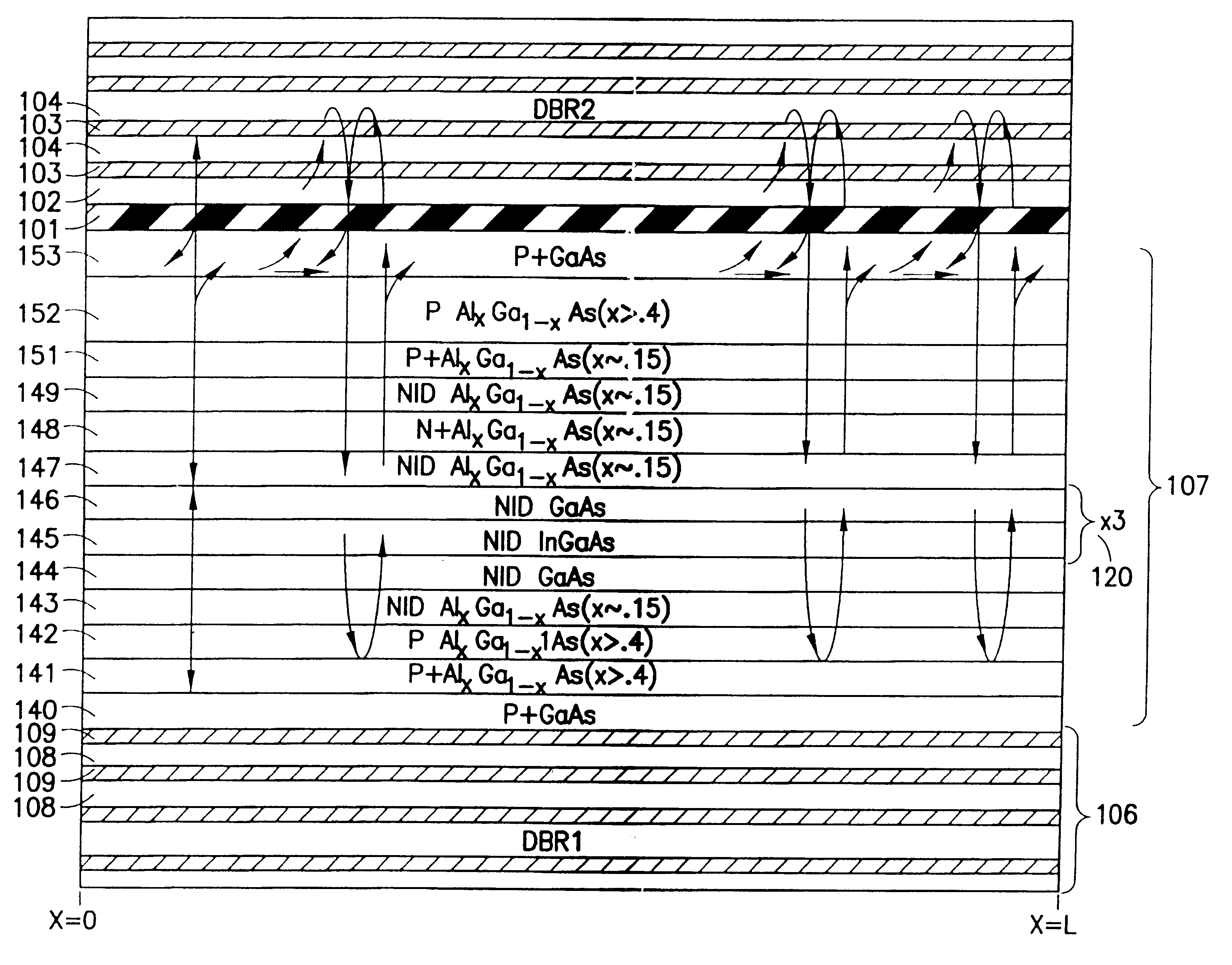

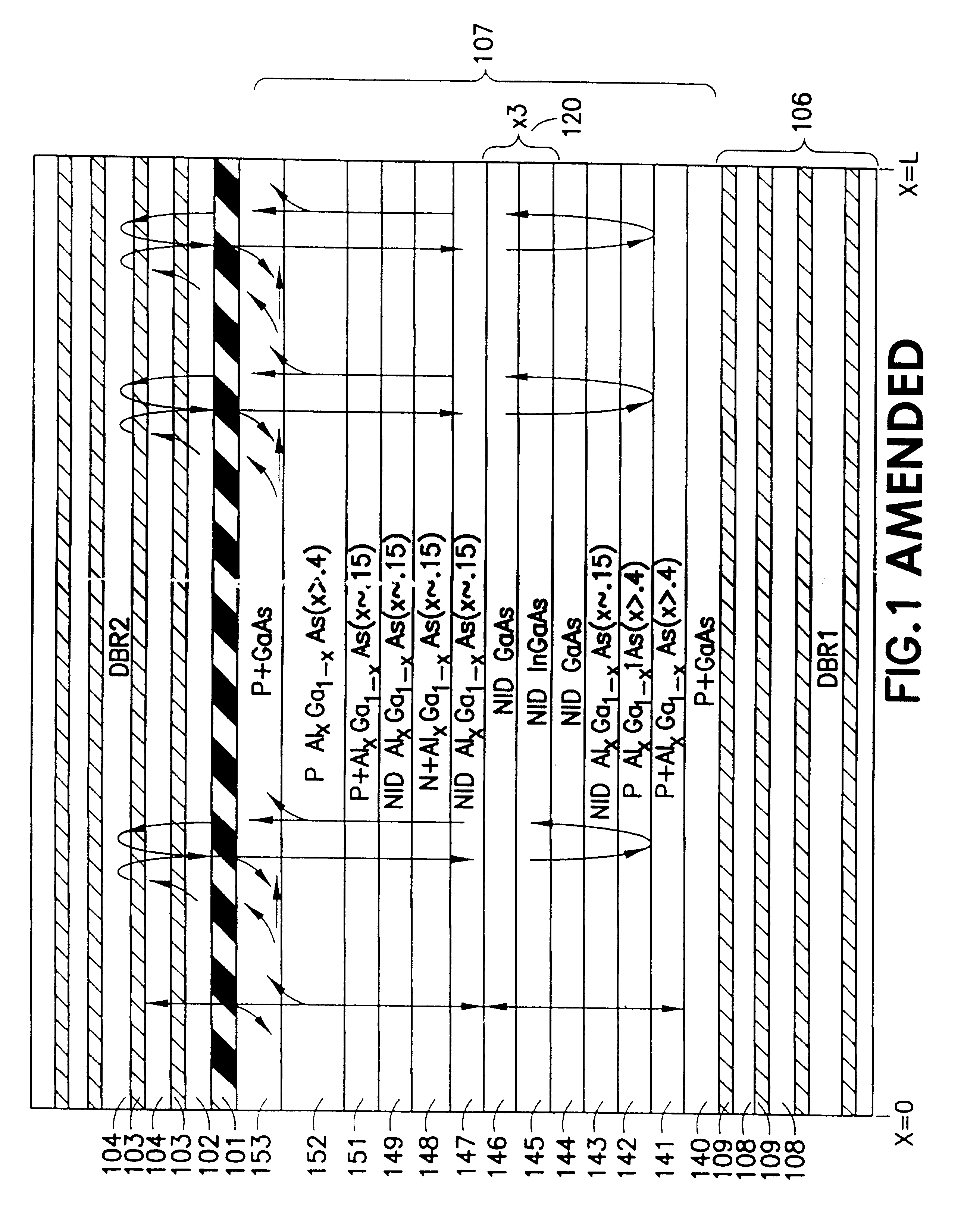

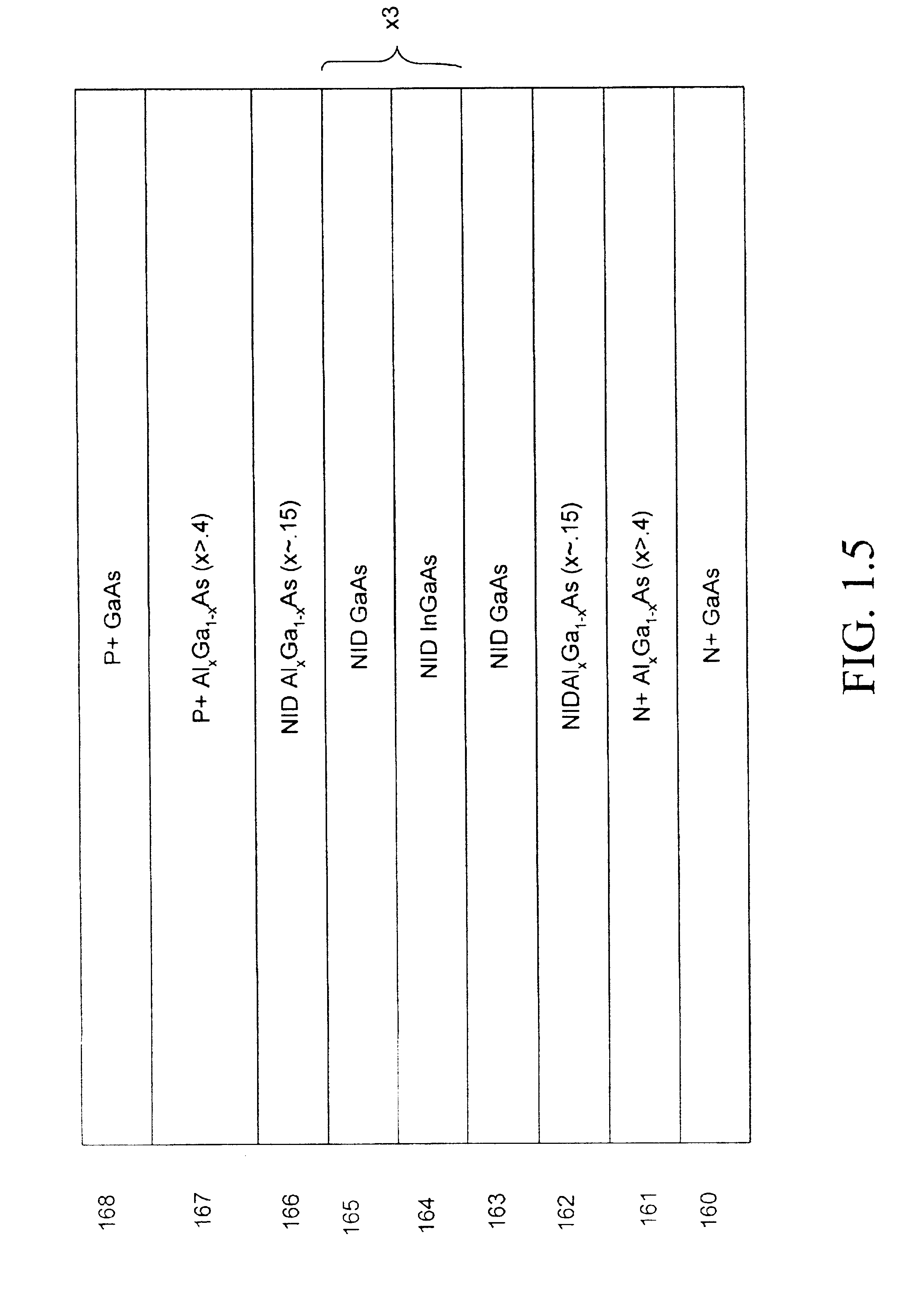

FIGS. 1,2,3 shows the layers of a structure in accordance with a preferred embodiment and from which all the devices of the invention can be made. The semiconductor layer structure and fabrication are in accordance with the Inversion Channel Technology and have been described in detail in application Ser. No. 60 / 028,576. A vertical cavity laser is constructed comprised of: a lower DBR mirror 106 consisting typically of alternating layers 108 of GaAs and 109 of AlAs which itself will be oxidized during the fabrication to form layers 109 of AlxOy, a active laser cavity 107 consisting of the standard SCH (separate confinement heterostructure) semiconductor laser structure containing say 3 quantum wells 120 which may be the laser structure of the inversion channel laser as discussed here or the conventional pn laser structure, a top DBR mirror consisting of alternating layers 101, 102, 103, and 104 of two deposited dielectrics. For the inversion channel laser this structure consists of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com