Apparatus and method for operating internal combustion engines from variable mixtures of gaseous fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

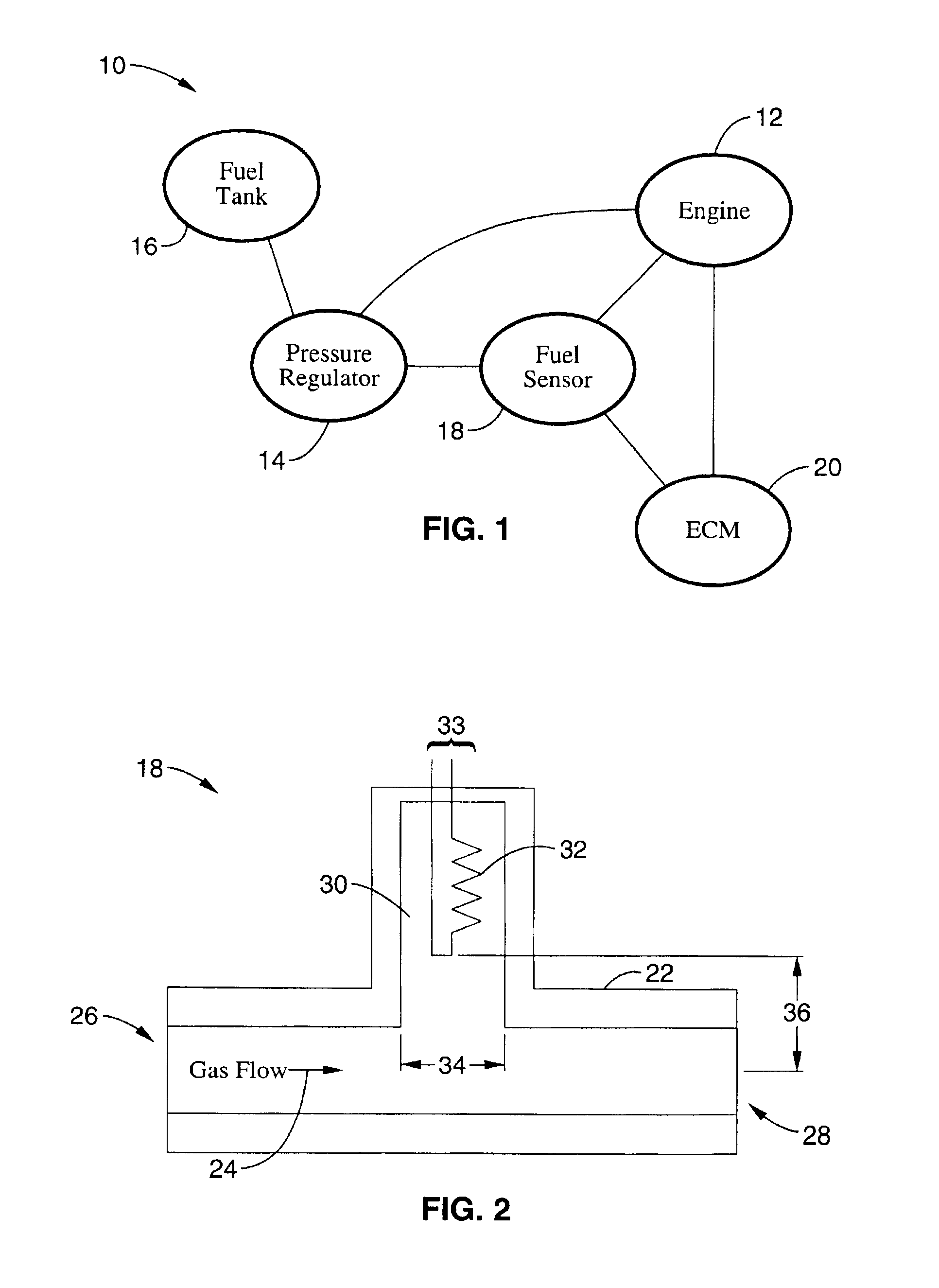

[0059]Care should be taken in designing the structure of the fuel sensor as the internal diameter 34 of the branched line for the sensing element and the distance between sensor element and fuel flow line 36 have been found to be important considerations in providing an adequate sensor signal level with a sufficiently rapid response time. By way of example, a suitable fuel sensor structure was fabricated with a chamber having a diameter 34 of about one-half centimeter (0.53 cm actual diameter used in testing) whereas filament 30 was offset 36 from the center of the gas flow passageway by a distance of about two centimeters (2.3 cm actual offset utilized in testing). It will be appreciated therefore that high signal levels and low susceptibility to gaseous flow rate were obtained with the offset distance being approximately four times (4×) that of the chamber diameter. It should also be appreciated, however, that the filament may be isolated from the convective flow using alternative...

example 2

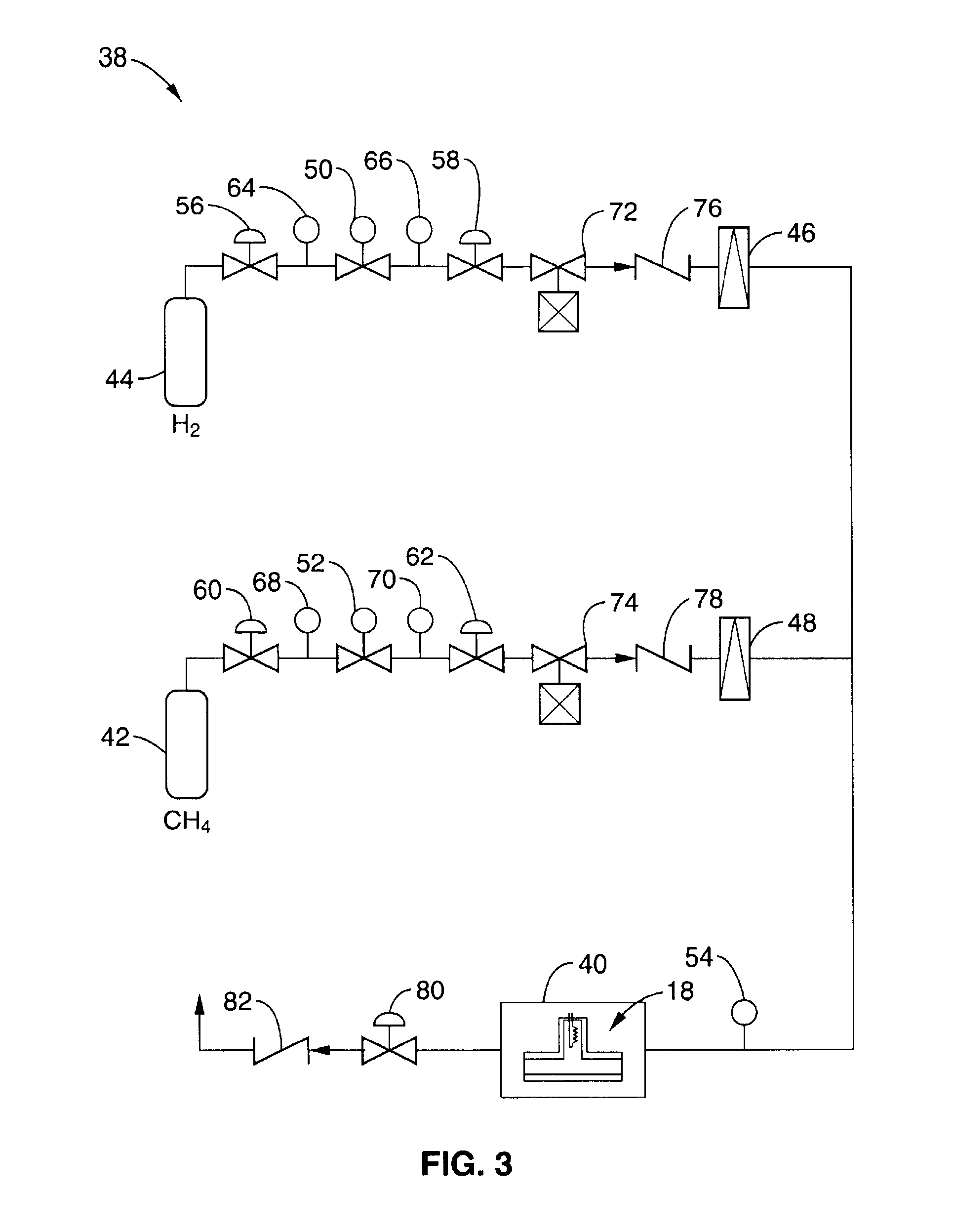

[0061]FIG. 3 illustrates a sensor test bench that was utilized for testing gaseous fuel composition sensor 18 as shown in FIG. 2. Test measurements were taken with fuel composition sensor 18 positioned within a temperature controlled oven 40. Oven temperature was measured utilizing an integrated circuit temperature sensor, specifically a model LM35 from National Semiconductor Incorporated®. The temperature sensor was utilized to control the temperature in conjunction with a personal computer to provide feedback for any desired value from ambient temperature to about 350 degrees Kelvin. Two kinds of calibration were performed with sources of pure methane 42 or pure hydrogen 44 that could be fed into fuel composition sensor 18 simultaneously, or sequentially, with the operation of a solenoid valve. The desired gas flow rate was adjusted by a needle valve and a ball flow meter 46, 48 for a range of flow situations from a static, no flow condition, to about two liters per minute. A cali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com