Method for synthesizing homopolymer and copolymers in alcohol-water system

A synthesis method and technology of copolymers, applied in the field of polymer synthesis, can solve the problems of difficult large-scale industrial production, complex process and equipment, and achieve the effects of less types and amounts of use, wide applicability and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

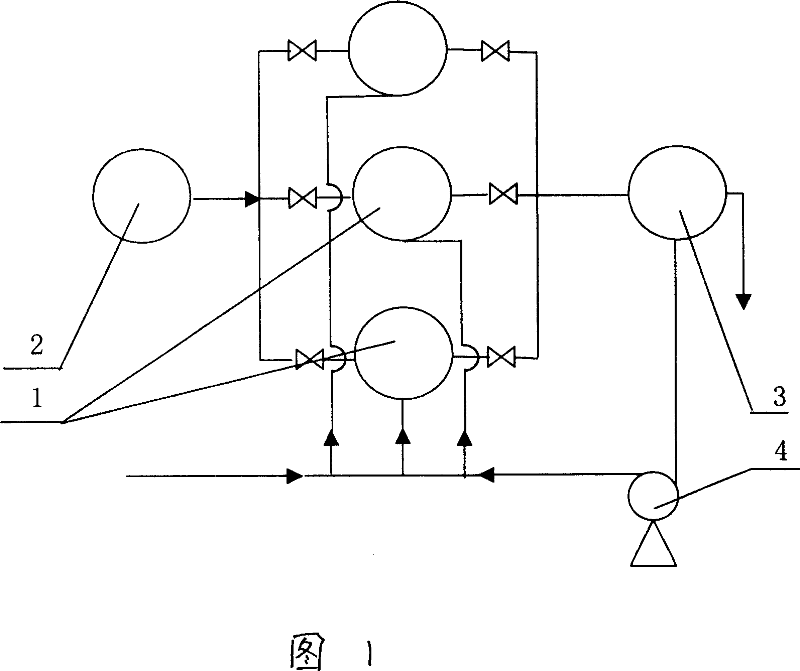

[0020] Example 1.a, raw material mixing: 100 kg of mixed monomers with a mass content of 80% vinylidene chloride and 20% vinyl chloride were mixed with 100 kg of water to form a mixed system with a total monomer mass fraction of 50%, adding 2% by mass of sodium lauryl sulfate, 1% of cetyl alcohol, 1% of ammonium persulfate and sodium sulfite are used as an initiator and an appropriate amount of stabilizer and plasticizer, and are rapidly stirred and emulsified in a mixer (2). b. Adding alcohol: the above-mentioned mixed raw materials are sent into the jacketed heating reaction kettle (1) through valve switching, and 5% ethanol by mass based on water is added under rapid stirring in the reaction kettle. c. Polymerization reaction: after purging the inside of the reactor (1) with an inert gas such as nitrogen, react at 50° C. for 2 hours. d. Separation: The reaction product is separated from ethanol and unreacted monomers by the alcohol-water separator (3) to obtain vinylidene c...

Embodiment 2

[0021] Example 2.a, raw material mixing: mix 100 kg of mixed monomers with 90% vinylidene chloride mass content and 10% vinyl chloride mass content with 100 kg water to form a mixed system with a total monomer mass fraction of 50%, and add 2% by mass of sodium lauryl sulfate, 1% of cetyl alcohol, 1% of ammonium persulfate and sodium sulfite are used as an initiator and an appropriate amount of stabilizer and plasticizer, and are rapidly stirred and emulsified in a mixer (2). b. Adding alcohol: the above-mentioned mixed raw materials are sent into the jacketed heating reactor (1) through valve switching, and 20% ethanol by mass based on water is added under rapid stirring in the reactor. c. Polymerization reaction: After purging the inside of the reactor (1) with an inert gas such as nitrogen, react at 80° C. for 2 hours. d. Separation: The reaction product is separated from ethanol and unreacted monomers by the alcohol-water separator (3) to obtain vinylidene chloride and viny...

Embodiment 3

[0022] Example 3.a, raw material mixing: mix 100 kg of mixed monomers with 80% vinylidene chloride mass content and 20% styrene mass content with 233 kg water to form a mixed system with a total monomer mass fraction of 30%, and add 1% by mass of sodium lauryl sulfate, 2% cetyl alcohol, 0.2% ammonium persulfate and sodium sulfite are used as an initiator and an appropriate amount of stabilizer and plasticizer, and are rapidly stirred and emulsified in a mixer (2). b. Alcohol addition: the above-mentioned mixed raw materials are sent into the jacketed heating reactor (1) through valve switching, and 5% methanol by mass based on water is added under rapid stirring in the reactor. c. Polymerization reaction: after purging the inside of the reactor (1) with an inert gas such as nitrogen, react at 50° C. for 3 hours. d. Separation: the reaction product is separated from methanol and unreacted monomers by the alcohol-water separator (3) to obtain vinylidene chloride and styrene copo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com