Process for preparing acrylic amide-acrylic sodium polymer nano particle micro emulsion

A technology of sodium acrylate and acrylamide, which is applied in the field of preparation of acrylamide-sodium acrylate polymer nanoparticle microemulsion, can solve the problems of fish-eye insoluble matter cost, slow powder dissolution rate, complicated preparation process, etc., and achieve low cost , short production cycle and simple preparation system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

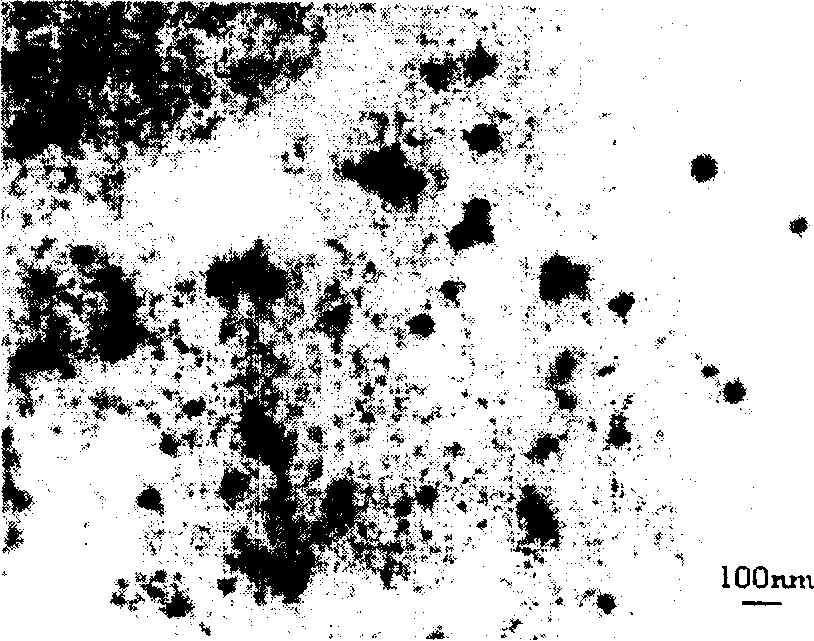

Image

Examples

preparation example Construction

[0028] Preparation process route of the present invention:

[0029] (1) Preparation of monomer aqueous solution: after acrylic acid (AA) is neutralized into sodium acrylate (SA) with sodium hydroxide, the monomer aqueous solution of required concentration is prepared according to the mass ratio of SA and AM;

[0030] (2) Prepare emulsifier solution: dissolve the emulsifier in mineral spirits, and fully emulsify for 30 minutes under slow stirring;

[0031] (3) Microemulsion polymerization: Slowly add the aqueous monomer solution dropwise into the emulsifier solution (30-45°C water bath), at a certain stirring speed, blow nitrogen to drive oxygen, and after blowing nitrogen at a constant temperature for 1 hour, add the required amount of initiator Agent (NH)4S2O8 and NaHSO3, under the protection of nitrogen, initiate polymerization at 40°C, and react for about 1 hour to obtain a transparent AM-SA polymer nanoparticle microemulsion;

[0032] (4) Preparation of powder: after the ...

Embodiment 1

[0036] In the four-necked flask that thermometer, reflux condenser, nitrogen conduit and dropping funnel are equipped with, add 500g kerosene, then add Span80 emulsifier 39.60g, Tween60 emulsifier 20.40g (HLB8.0) and be dissolved in kerosene, in collection Fully emulsify for 30 minutes under slow stirring under a hot magnetic stirrer; add 61.5g AA and dissolve it in 200g of 20% sodium hydroxide deionized aqueous solution, and neutralize it into SA; add 123g of AM again to make monomer aqueous solution (AM: SA=2:1); Slowly add the monomer aqueous solution into the emulsifier solution (30-45°C water bath), at a certain stirring speed, blow nitrogen to drive oxygen, and after constant temperature nitrogen blowing for 1h, add the total amount of monomer 0.9‰ initiator (NH)4S2O80.0874g and NaHSO30.0786g (1:0.9), under the protection of nitrogen, initiate polymerization, and the initiation reaction is carried out at 40°C, and the reaction is about 1h, and the transparent AM-SA polyme...

Embodiment 2

[0039] The preparation process route is the same as in Example 1, only the components of the reaction system are changed.

[0040] Change the consumption of composite emulsifier (the amount of emulsifier is 10% of the total mass of the oil phase) and the HLB value (being 9.6), that is, Span80 emulsifier 25g, Tween60 emulsifier 25g are dissolved in 500g kerosene, under the heat collecting magnetic stirrer Fully emulsified for 30 minutes under slow stirring; 36.9gAA was dissolved in 12% sodium hydroxide deionized aqueous solution of 200g, and neutralized into SA; then added 147.6gAM (AM:SA=4:1) to make monomer aqueous solution; The aqueous solution is added dropwise to the emulsifier solution, and the initiator (NH)4S2O80.0326g and NaHSO30.0228g (1:0.7) of 0.3‰ of the total amount of monomers are added, and the initiation reaction is carried out at 40°C, and the reaction is about 1h, that is, Transparent AM-SA polymer nanoparticle microemulsion. The amount of emulsifier is 10% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com