Method for solvent thermal reaction preparation of alpha-Si3N4 monocrystal nano wire

A solvothermal reaction, single crystal nanotechnology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of product impurity and high reaction temperature, achieve low reaction temperature, simple and easy to control reaction, Achieve the effect of industrialized production with large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1: Preparation of α-Si by reaction of magnesium nitride and silicon tetrachloride 3 N 4 Nanowires

[0016] Take 2 millimoles of magnesium nitride and 5 millimoles of silicon tetrachloride, put them into a stainless steel reaction kettle lined with a hafnium alloy, use nitrogen to remove the air in the kettle, seal them and place them in a resistance crucible boiler, respectively, at 550 ° C , 600°C and 700°C (furnace temperature controlled at ±5°C) for 5-24 hours; after stopping heating, cool the reaction kettle to room temperature naturally; open the kettle and remove unreacted SiCl 4 , the resulting product was washed with acid and water, centrifuged and dried to obtain α-Si 3 N 4 product. Vacuum-dried at 50°C for 6 hours to obtain an off-white powder product.

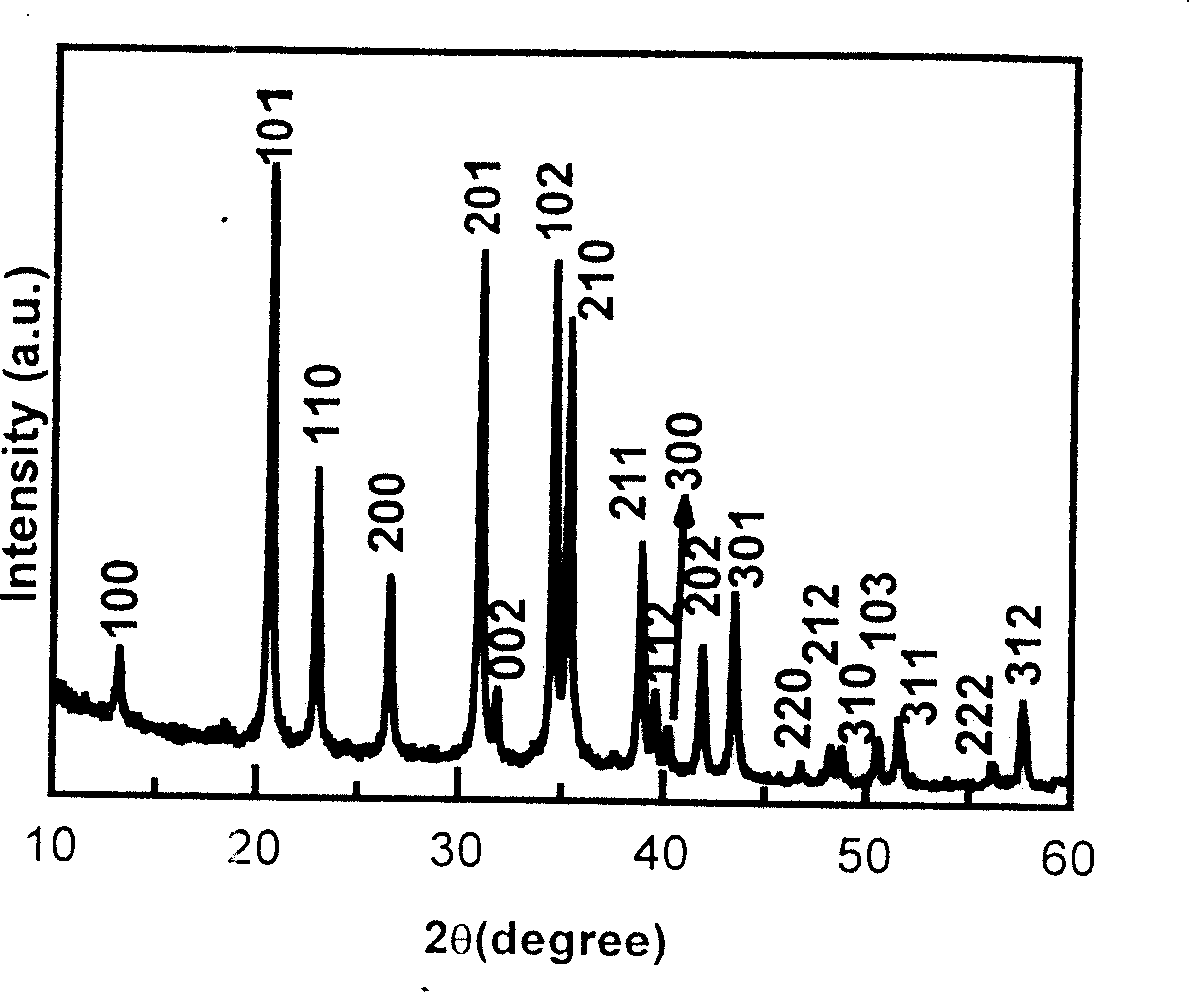

[0017] Adopt Japan Rikagu DmaxγA X-ray powder diffractometer to take Cu Kα ray (wavelength λ=1.54178 ) is a diffraction light source for X-ray diffraction analysis of the product.

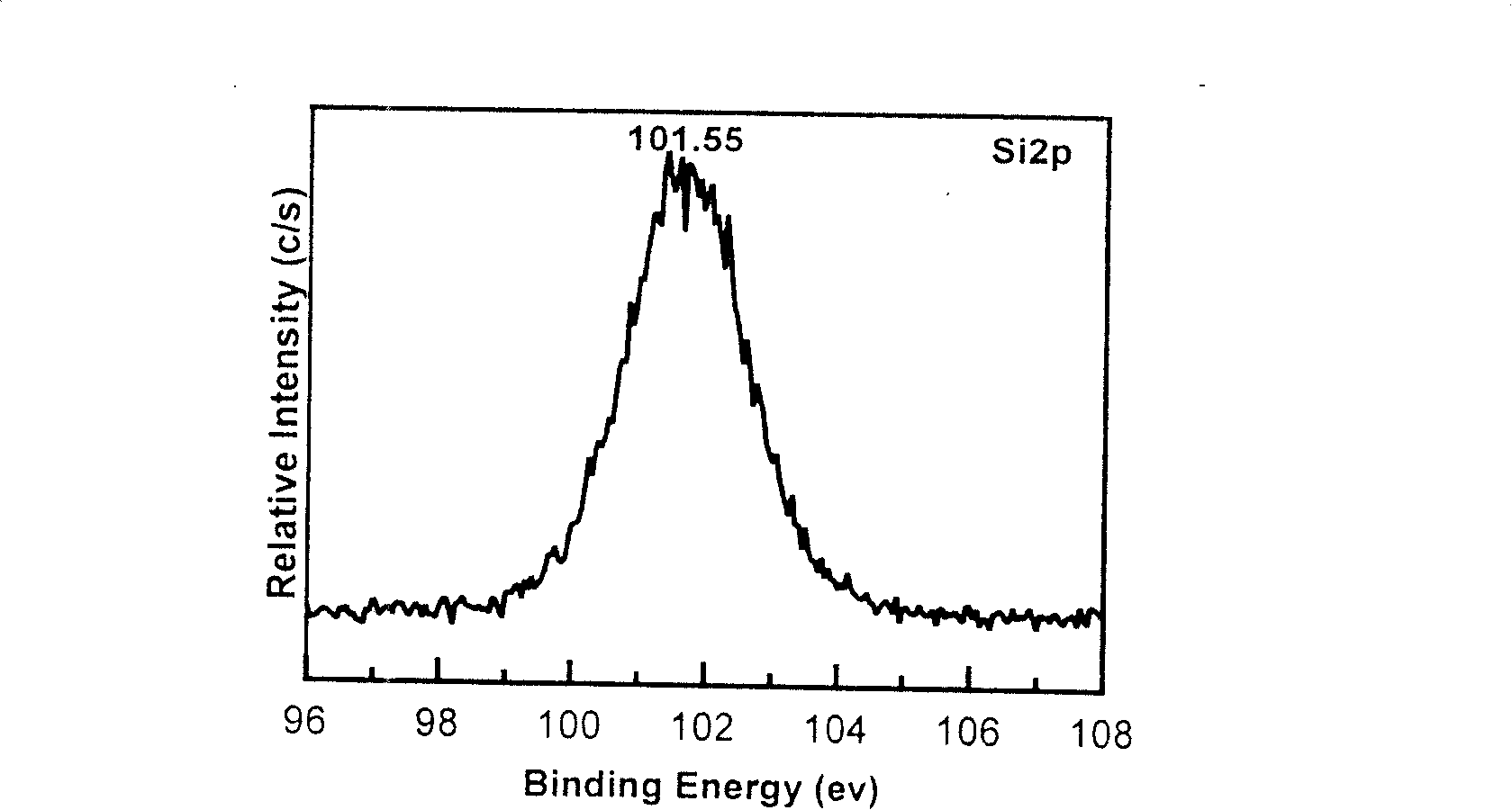

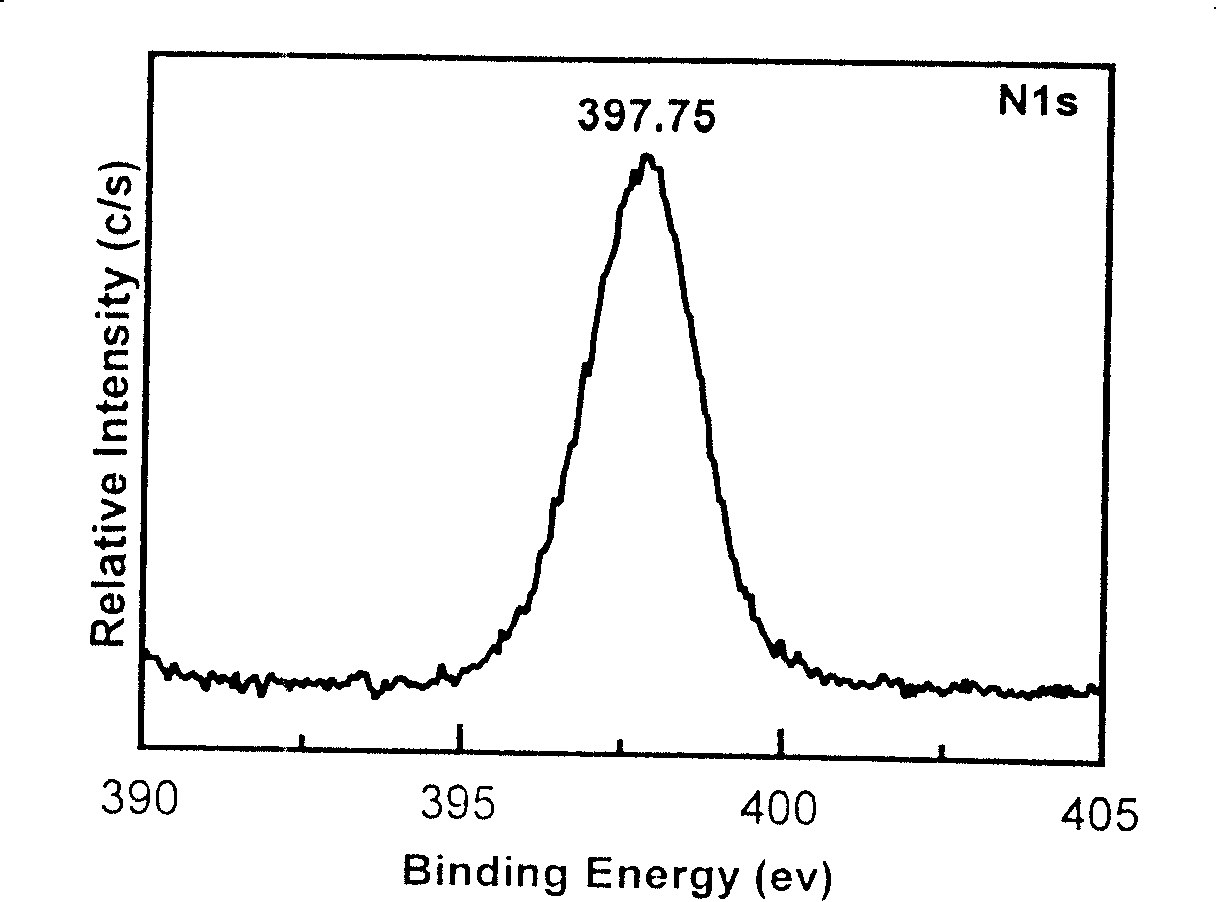

[0018] fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com