Method and apparatus of using molten lead iodide to grow monocrystal

A growth method and lead iodide technology, applied in crystal growth, chemical instruments and methods, single crystal growth and other directions, can solve the problem that the decomposition of lead iodide and the evaporation of iodine cannot be completely inhibited, it is difficult to obtain lead iodide single crystals, and precipitation Inconsistent directions, etc., to achieve the effect of convenient cutting and cleavage, low stress, and high utilization of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

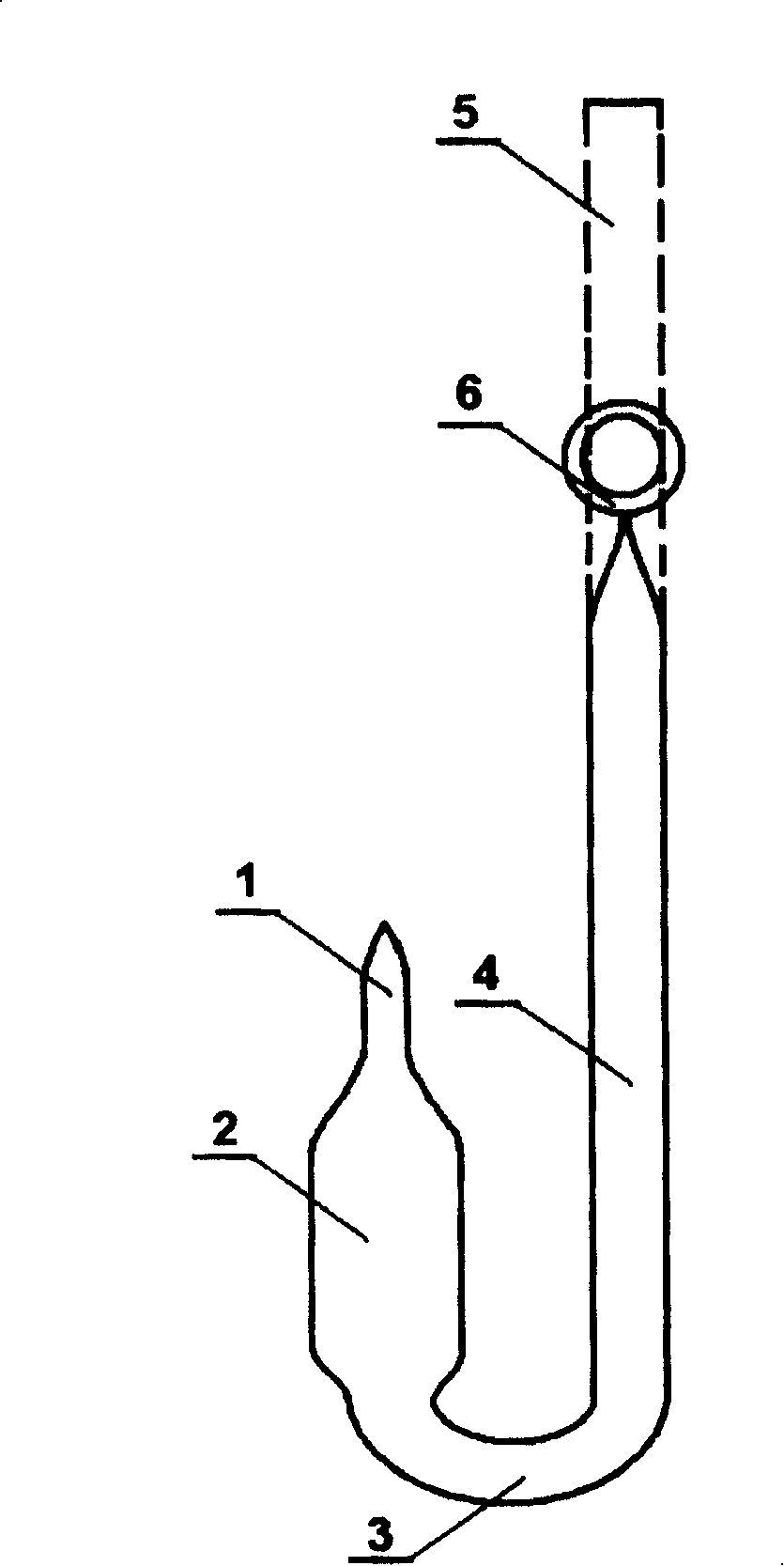

[0035] The present embodiment prepares the lead iodide single crystal whose size is Φ15 millimeters × 30 millimeters, and the best plan is to use the quartz tube of internal diameter Φ15 millimeters × 500 millimeters to make such as figure 1 U-shaped ampoule shown.

[0036] The processing steps of the present embodiment are as follows:

[0037] 1. Clean the ampoule

[0038] Rinse the ampoules with deionized water and allow to dry to remove impurities.

[0039] 2. Filling and degassing the ampoule

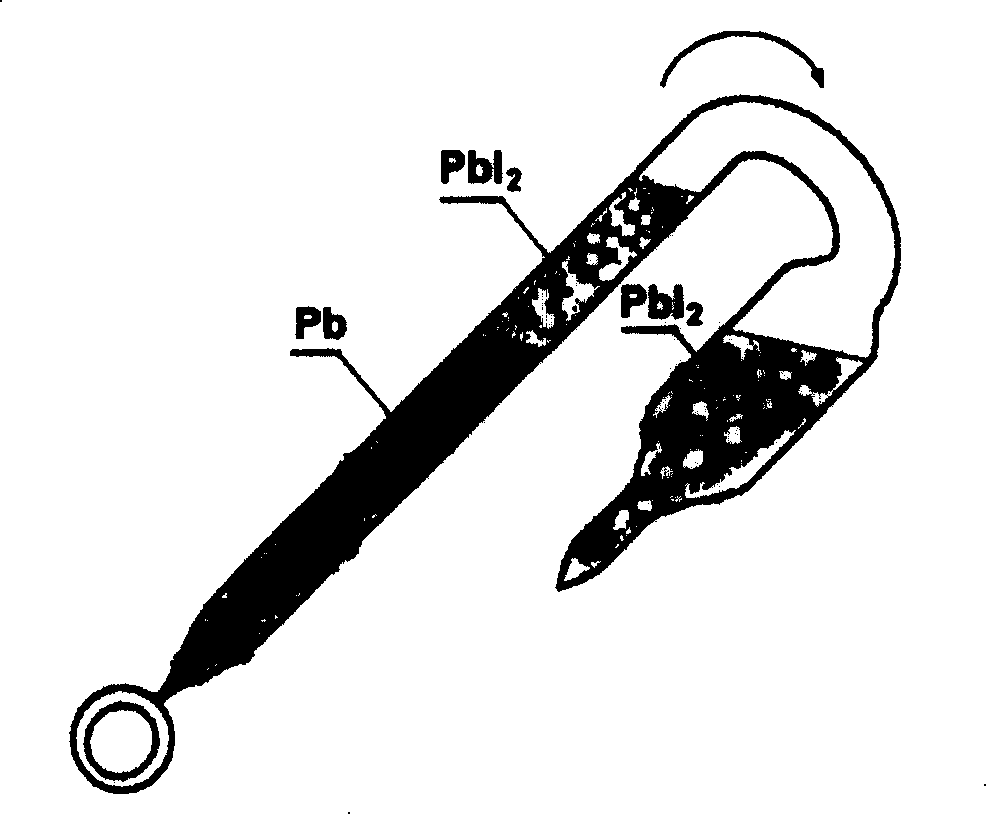

[0040] Measure the volume of ampoule seed crystal bag 1, growth chamber 2, connector 3 and lead liquid pipe 4 with the method of filling water, to determine the quality that needs to pack lead iodide polycrystalline raw material and lead powder; The lead polycrystalline raw material and lead powder are loaded into the cleaned ampoule in turn, and in the charging process, in order to ensure that the lead iodide melt can be pressed into the growth chamber 2 and fill the seed crysta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com