Synthesis method of cobaltous oxide nano-tube

A technology of cobaltous oxide and synthesis method, applied in the directions of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complex reaction process, poor morphology, low yield, etc., and achieve easy control of production conditions, The effect of high product purity and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

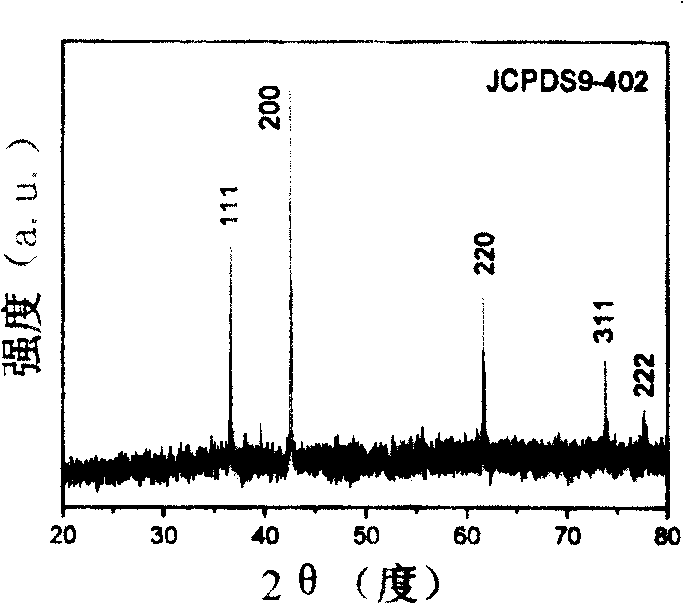

[0019] Weigh 0.00025mol of cobaltous nitrate and place it in a beaker, add 10ml of deionized water to dissolve it, then add 10ml of 0.1M ammonia solution dropwise under rapid stirring, continue to stir for 10 minutes after the precipitation is formed, and then dissolve the obtained Precipitation is centrifuged and washed until the pH of the washing solution is 8, and the precipitate is redispersed in 20ml of methanol solution with a weight concentration of 100%, and then according to the washed precipitate: hydrazine hydrate=1:0.1 parts by weight, add hydrazine hydrate as a reducing agent and Stir until dissolved, transfer the stirred and dissolved mixture into a closed stainless steel reactor, react at 250°C for 5 hours, cool to room temperature after the reaction, then wash the obtained product with deionized water and dry at 50°C get the product. The product was identified as cobaltous oxide by X-ray powder diffraction; the morphology of the product was nanotubes as detecte...

Embodiment 2

[0021] Weigh 0.00025mol of cobaltous nitrate and place it in a beaker, add 10ml of deionized water to dissolve it, then add 10ml of 0.2M ammonia solution dropwise under rapid stirring, continue stirring for 5 minutes after the precipitation is formed, and then dissolve the obtained Precipitation is centrifuged and washed until the pH of the washing liquid is 6, and the precipitation is redispersed in 25ml of weight concentration in methanol aqueous solution of 3%, then according to the washed precipitation: hydrazine hydrate=1: 10 parts by weight, add hydrazine hydrate as reducing agent and Stir until dissolved, transfer the stirred and dissolved mixture into a closed stainless steel reactor, react at 100°C for 30 hours, cool to room temperature after the reaction, then wash the obtained product with deionized water and dry at 80°C get the product. The product was identified as cobaltous oxide by X-ray powder diffraction; the morphology of the product was nanotubes as detected...

Embodiment 3

[0023] Weigh 0.00025mol of cobaltous nitrate and place it in a beaker, add 10ml of deionized water to dissolve it, then add 10ml of 0.2M ammonia solution dropwise under rapid stirring, continue to stir for 8 minutes after the precipitation is formed, and then dissolve the obtained Precipitation is centrifuged and washed until the pH of the washing liquid is 7, and the precipitation is redispersed in 30ml of weight concentration in methanol aqueous solution of 20%, then according to the washed precipitation: hydrazine hydrate=1: 5 parts by weight, add hydrazine hydrate as reducing agent and Stir until dissolved, transfer the stirred and dissolved mixture into a closed stainless steel reactor, react at 180°C for 20 hours, cool to room temperature after the reaction is complete, then wash the obtained product with deionized water, and dry it in a conventional vacuum get the product. The product was identified as cobaltous oxide by X-ray powder diffraction; the morphology of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com