Winding-structured engine tail gas processing device with metal as carrier

A technology for exhaust gas treatment and metal carrier, applied in engine components, machines/engines, mechanical equipment, etc., can solve the problem of lack of bonding technology between metal sheet substrate and shell, low exhaust gas purification efficiency, and high pressure resistance of engine exhaust system and other problems, to achieve the effect of not easy brittle cracking, strong shock resistance, and reducing exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

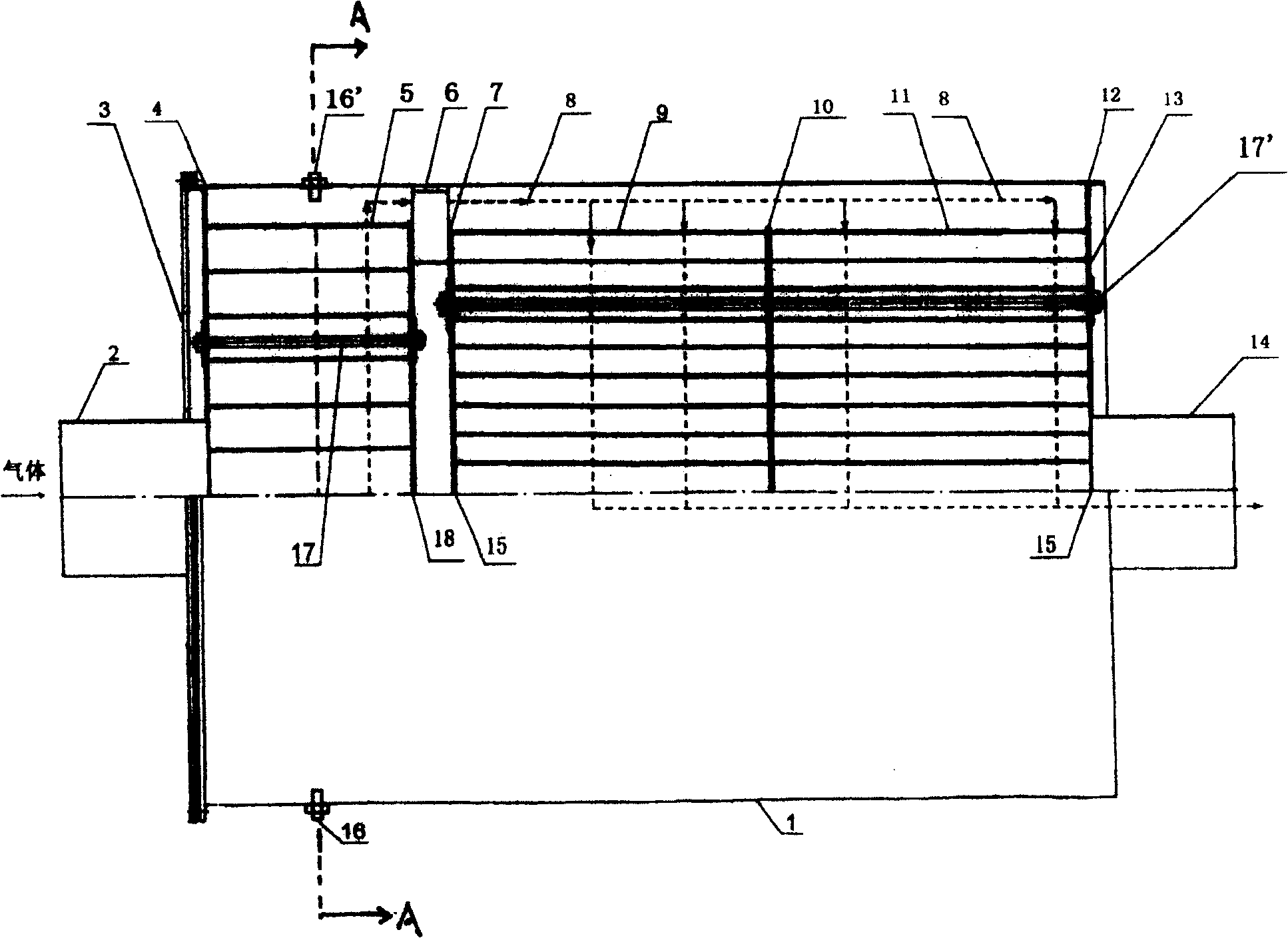

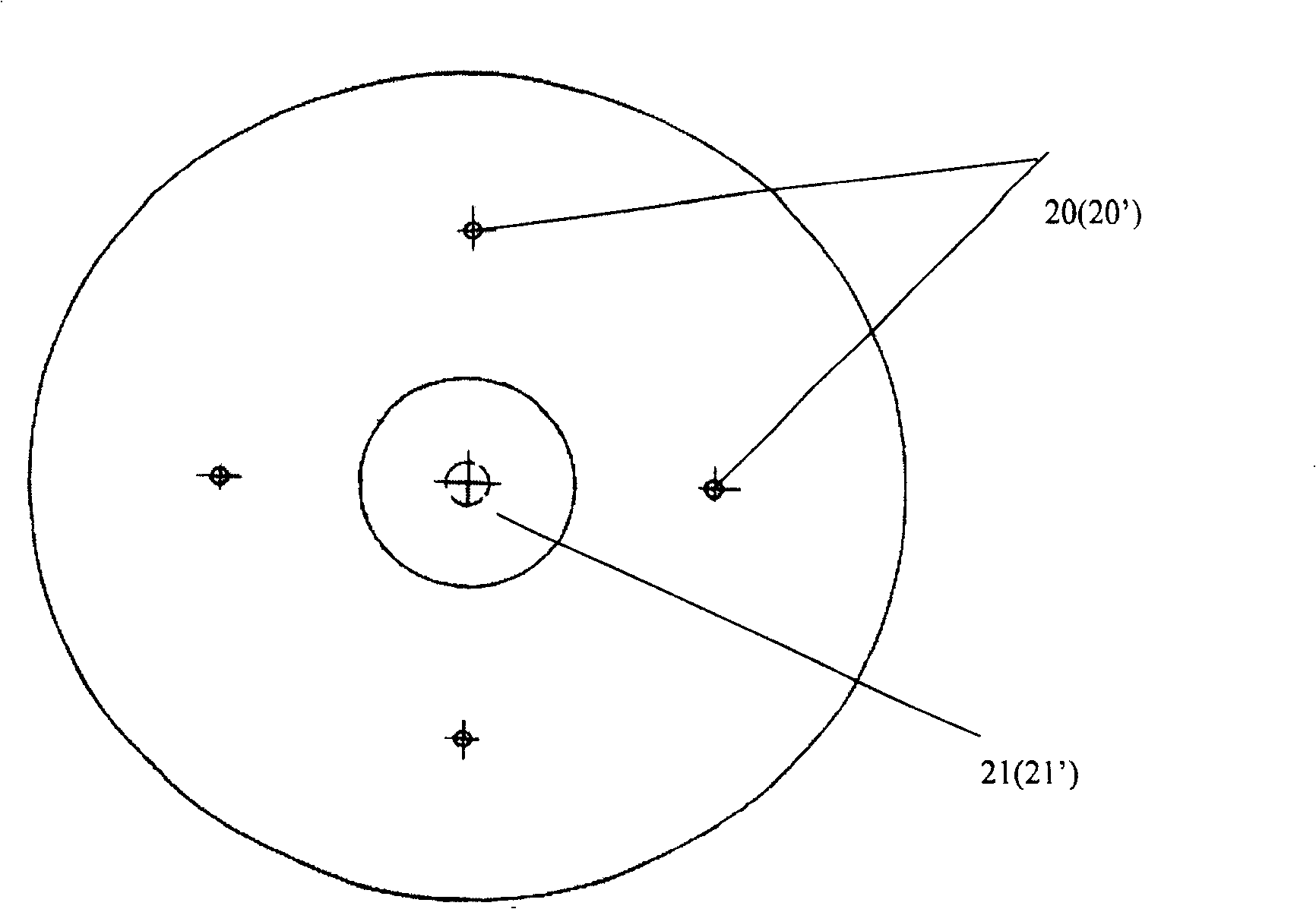

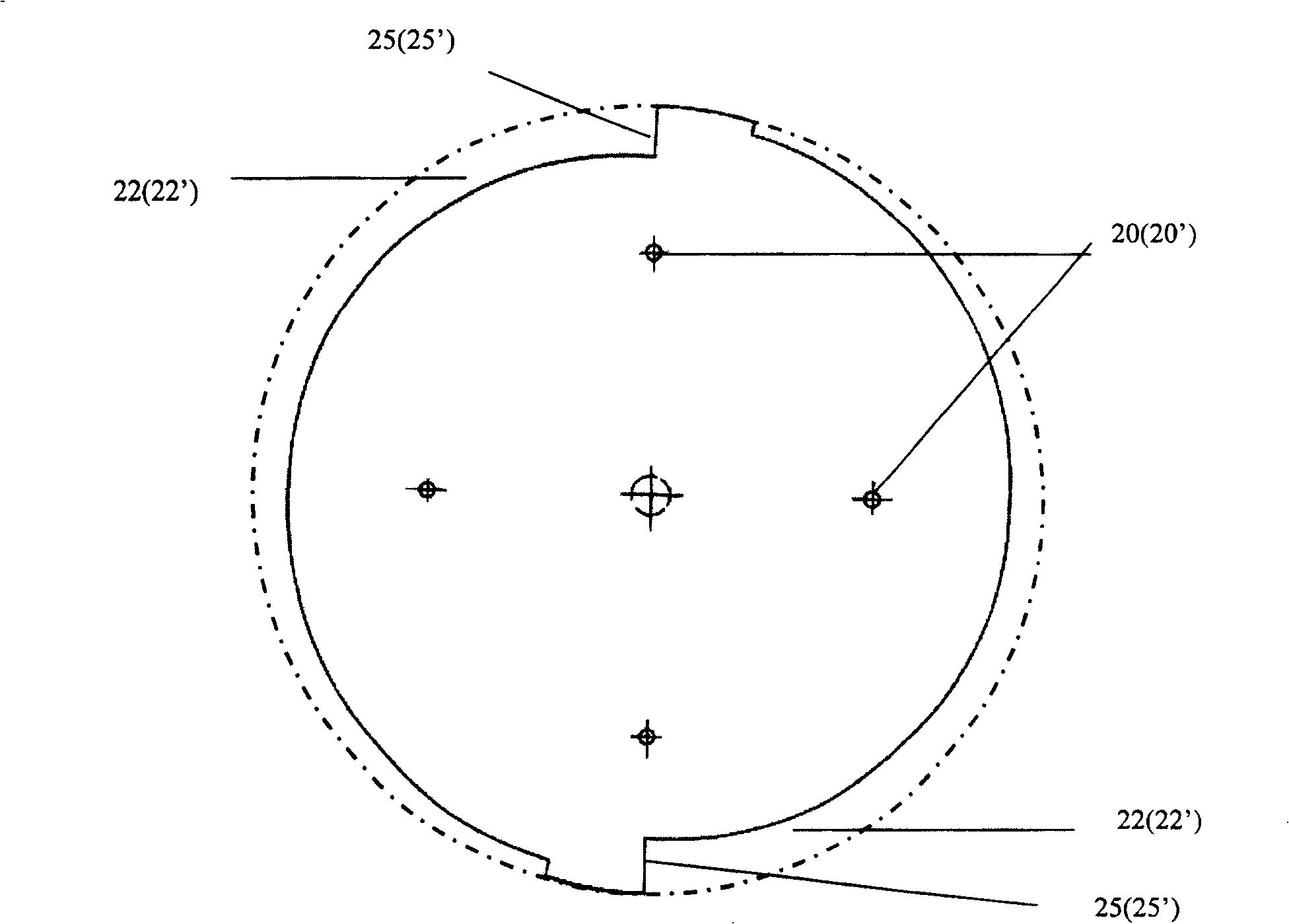

[0057] like figure 1 , in the catalytic first stage, the gas flows in from the center of the baffle 4 and flows into the second stage 15 along the outer edge of the baffle 18 . Catalytic secondary 15 is to be made of the second catalytic corrugated band 9 and the 3rd catalytic corrugated band 11 that are twisted into S shape with two identical lengths and width, the catalytic corrugated band of catalytic secondary 15 is by means of metal baffle plate 10 (such as figure 2 , 3 , 4) apart, and the ceramic baffles 4, 18 clamp the first catalytic fold belt 5, wear it with a pin 17, and fix it on the inlet cover 3 of the purifier, and the metal baffles 7, 10, 12 are also clamped The second catalytic fold belt and the third catalytic fold belt are fixed on the air outlet cover 13 through pins 17 ′. gas flow path such as figure 1 As shown in 8, in the first stage, the gas enters from the hole in the middle of the baffle plate 4 and flows along the S-shaped fold belt, and finally f...

Embodiment 2

[0085] a) Heating metal strip width:

[0086] After the diameter of the intake pipe and the inner cylinder is determined, we can determine the width of the heating metal belt according to the required power and the actual vehicle model. The width of the heating metal belt is D 1 Generally between 120mm-160mm (can be determined according to the actual situation); the metal thickness is h (0.05mm-0.5mm), the height of the metal corrugated is H (0.5-3mm), and the required power is W (2-2.5kw ).

[0087] The cross-sectional area of the intake pipe in this patent is F 1 =6362mm 2 , the diameter R of the inner tube 0 =175mm, metal bandwidth D 1 =122mm, the height H of the corrugated metal band=1.8mm, the thread pitch is M 1

[0088] Then there are: M 1 =F 1 ÷D 1 +H

[0089] So: M 1 =54mm

[0090] Power W=2.1kw, resistivity ρ=1.09*10 -6 , the voltage of the car battery is U (usually 24V), the thickness of the metal is h=0.1mm, and the resistance of the metal strip is R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com