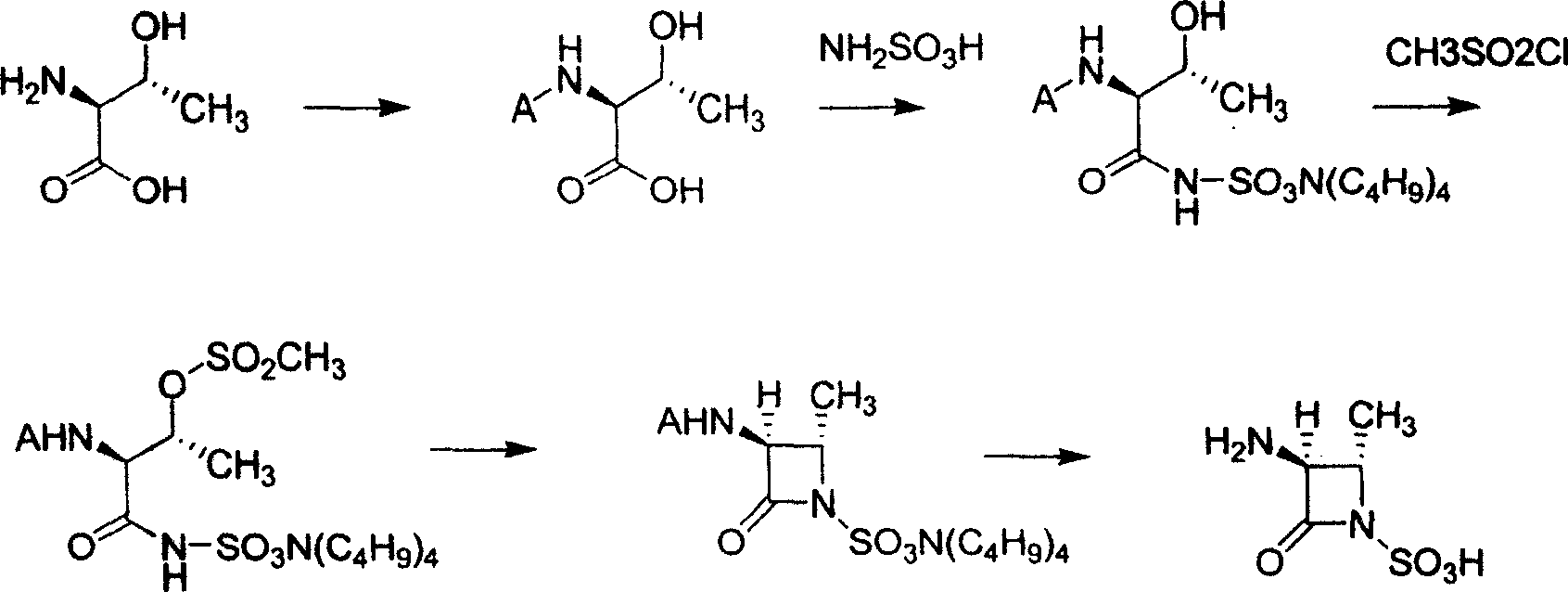

Process of synthesizing (2S-trans)-3-methyl-4-oxo-1-azacyclo butyl sulfonic acid

A technology of azetidine sulfonic acid and sulfamic acid, applied in directions such as organic chemistry, can solve problems such as low yield and difficult operation, and achieve the effects of improved yield, low cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

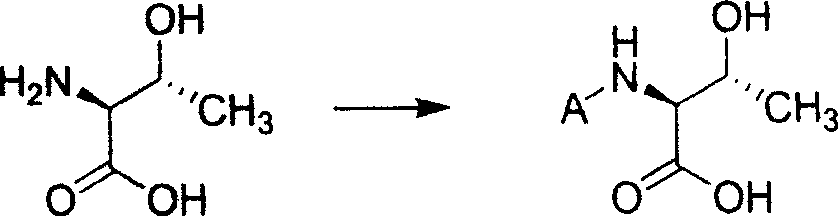

[0059] Step A:

[0060] In a 2L three-necked flask, add 350ml of water and 350ml of 1,4-dioxane, stir evenly, add 67.3g of L-threonine, 94.5ml of triethylamine, 181g of di-tert-butyl dicarbonate, and react at room temperature overnight. After the plate reaction is complete, add 500ml ethyl acetate, stir for 30 minutes, separate the organic layer, adjust the pH of the aqueous layer to 2~3 with hydrochloric acid, extract with ethyl acetate 300×3, combine the organic layers, and dry with anhydrous sodium sulfate. It was filtered and concentrated to obtain 115 g of colorless oil with a yield of 93%.

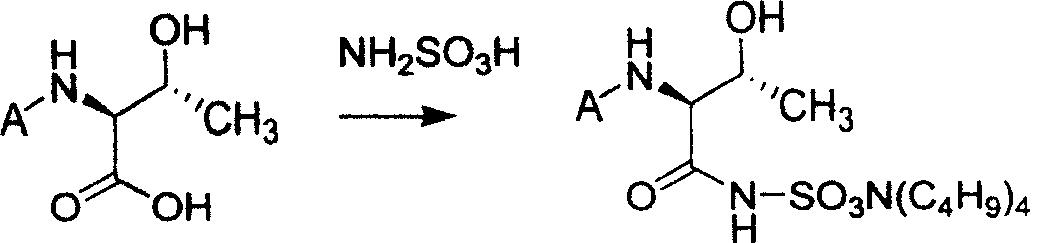

[0061] Step B

[0062] Take 11.2g of the product of step A, dissolve it in a 250ml three-necked flask with 100ml tetrahydrofuran, cool to -5℃ with an ice salt bath, add 7.2g 1-hydroxybenzotriazole, and add 11.7g N,N-dicyclohexylcarbodiimide After stirring for 30 minutes, add 5.5g sulfamic acid and 5.7g triethylamine. After reacting at low temperature for 1 hour, remove the ice bath, reac...

Embodiment 2

[0070] Step A:

[0071] In a 2L three-necked flask, add 350ml water and 350ml 1,4-dioxane, stir well, add 67.3g L-threonine, 94.5ml triethylamine, drop 144g benzyl chloroformate, the addition is complete After that, react overnight at room temperature. After the spotting reaction is complete, add 500 ml of ethyl acetate, stir for 30 minutes, separate the organic layer, adjust the pH of the aqueous layer to 2 to 3 with hydrochloric acid, extract with ethyl acetate 300×3, and combine the organic layers. It was dried with anhydrous sodium sulfate, filtered, and concentrated to obtain 136 g of a colorless oil with a yield of 95%.

[0072] Step B

[0073] Take 13g of the product of step A and dissolve it in a 250ml three-necked flask with 100ml of tetrahydrofuran, cool to -5°C in an ice-salt bath, add 7.2g of 1-hydroxybenzotriazole, and add 11.7g of N,N-dicyclohexylcarbodiimide, Stir for 30 minutes, add 5.5g sulfamic acid and 5.7g triethylamine, react at low temperature for 1 hour, rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com