Functional luminescent material and its prepn

A composite material and functional technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminous efficiency of devices, short service life of devices, etc., and achieve controllable polymerization process, good solubility and film-forming performance, The effect of clear product structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

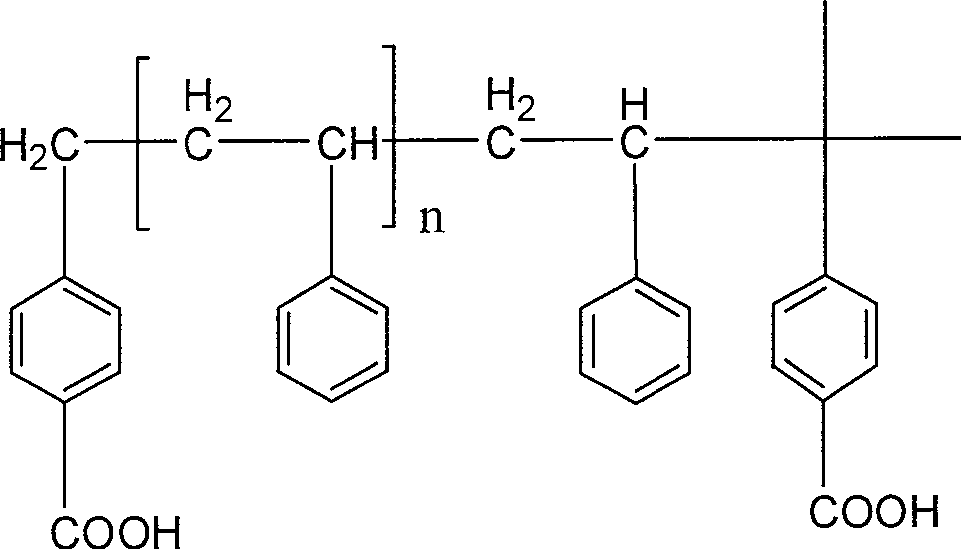

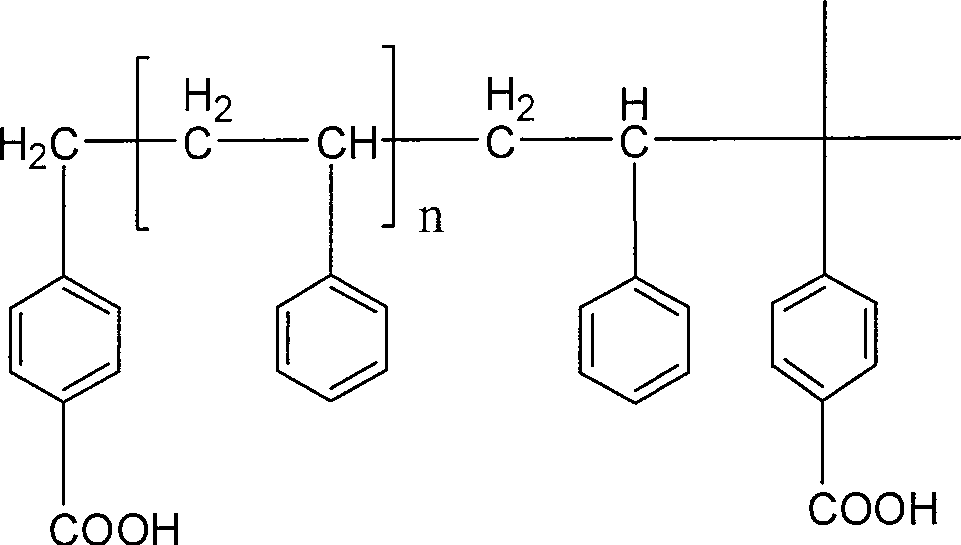

[0023] Example 1: Preparation of polystyrene containing benzoic acid units at both ends

[0024] (1) Atom Transfer Radical Polymerization of Styrene Initiated by 4-Chloromethylbenzoic Acid

[0025] Initiator 4-chloromethylbenzoic acid, catalyzer (the complex of cuprous chloride and 2,2'-bipyridine), styrene are added in the cyclohexanone solvent, make styrene / initiator / catalyst / partition The molar ratio of the body is 200 / 5 / 5 / 15, the mass ratio of styrene and cyclohexanone is 1:1, the polymerization system is polymerized under the condition of nitrogen protection and oxygen isolation, and the reaction is carried out at 130°C for 2-6 hours. Polymerization products were precipitated in excess methanol, dilute hydrochloric acid was added to remove the catalyst, and the solid product was filtered out and dried. The resulting polymer is polystyrene with terminal benzoic acid units.

[0026] (2) Synthesis of p-isopropylbenzoic acid-terminated polystyrene

[0027] Add 0.3g-0.6g of...

Embodiment 2

[0028] Example 2: Nano TiO 2 Modification of polystyrene with carboxylic acid at both ends

[0029] Dissolve 0.1g-0.5g of polystyrene obtained in Example 1 with carboxylic acid at both ends in chloroform, and drop 30ml of TiO 2 In the colloid, stir at room temperature for 1h-5h, let it stand for stratification, drop methanol into the lower layer (add an appropriate amount of NaCl aqueous solution in advance), and there will be a white precipitate, filter, add deionized water and ultrasonically shake to remove doped nanoparticles, filter and dry to obtain polymerization matter / nano-TiO 2 Composite system.

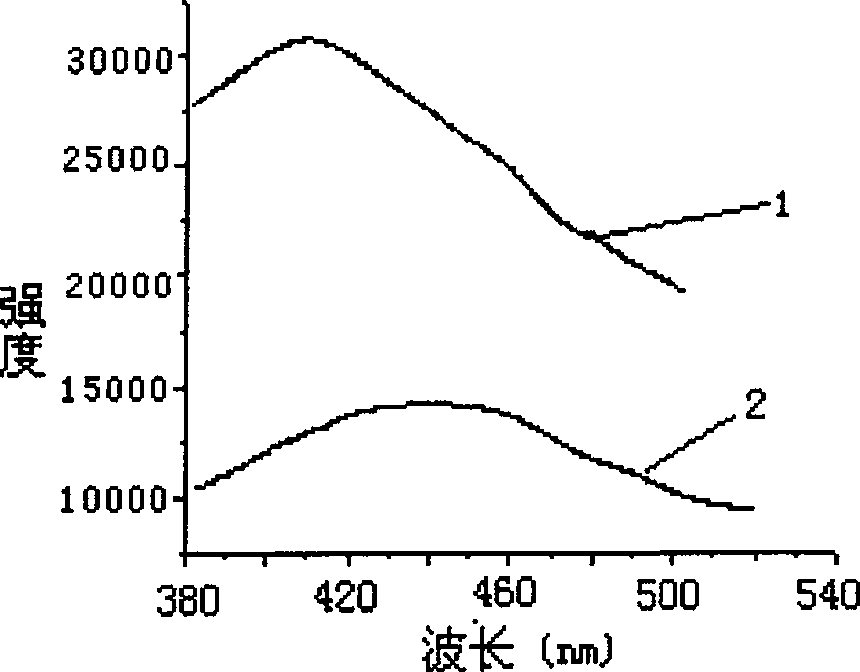

[0030] Referring to Figure 2, the fluorescence emission spectrum of the film of the polymer and the composite system: the emission peak of the composite system has a red shift of 35nm relative to that of the polymer. In the figure, curve 1 represents the fluorescence emission spectrum of the polymer; curve 2 represents the polymer / nano-TiO 2 Fluorescence emission spectra...

Embodiment 3

[0031] Embodiment 3: Nano-ZnO modification of polystyrene with carboxylic acid at both ends

[0032] Dissolve 0.1g-0.5g of polystyrene with both ends of carboxylic acid obtained in Example 1 in 15ml-30ml of chloroform, add excess nano-ZnO sol, stir and react at room temperature for 1-5h, then let it stand for stratification, and the lower layer Precipitate in methanol (pre-added saturated NaCl solution), filter, dissolve the obtained precipitate in tetrahydrofuran, precipitate in methanol again, add water and ultrasonically oscillate to remove doped nanoparticles, filter and dry to obtain a white powder that is polymerization matter / nano-ZnO composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com