Preparation process of nanometer composite titania/silica photocatalyst sol and transparent photocatalytic film

A nano-titanium dioxide and composite photocatalysis technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the environmental protection discount of water-based environmental protection coatings, accelerated aging of paint film coatings, and poor stability, etc. problem, to achieve the effect of low price, short operation cycle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Dilute 8ml titanium tetrachloride solution to 1000ml solution under ice-water bath and stirring condition, Ti 4+ The ion concentration is about 0.02mol / L, and the pH value is adjusted to 7 with ammonia water to obtain orthotitanic acid precipitation, which is washed to remove impurities. In this precipitation, add 40ml mass percentage concentration earlier and be 30% hydrogen peroxide solution, treat that after all dissolving, be 30% nitric acid adjustment pH value to be 2, then add 200ml particle diameter and be 8~20nm, The acidic silica aqueous sol with a pH value of less than 3 is refluxed at 100° C. for 3 hours to obtain a light yellow and transparent titanium dioxide / silica composite photocatalytic sol, and the particle size of the composite photocatalytic sol is 15-30 nm.

Embodiment 2

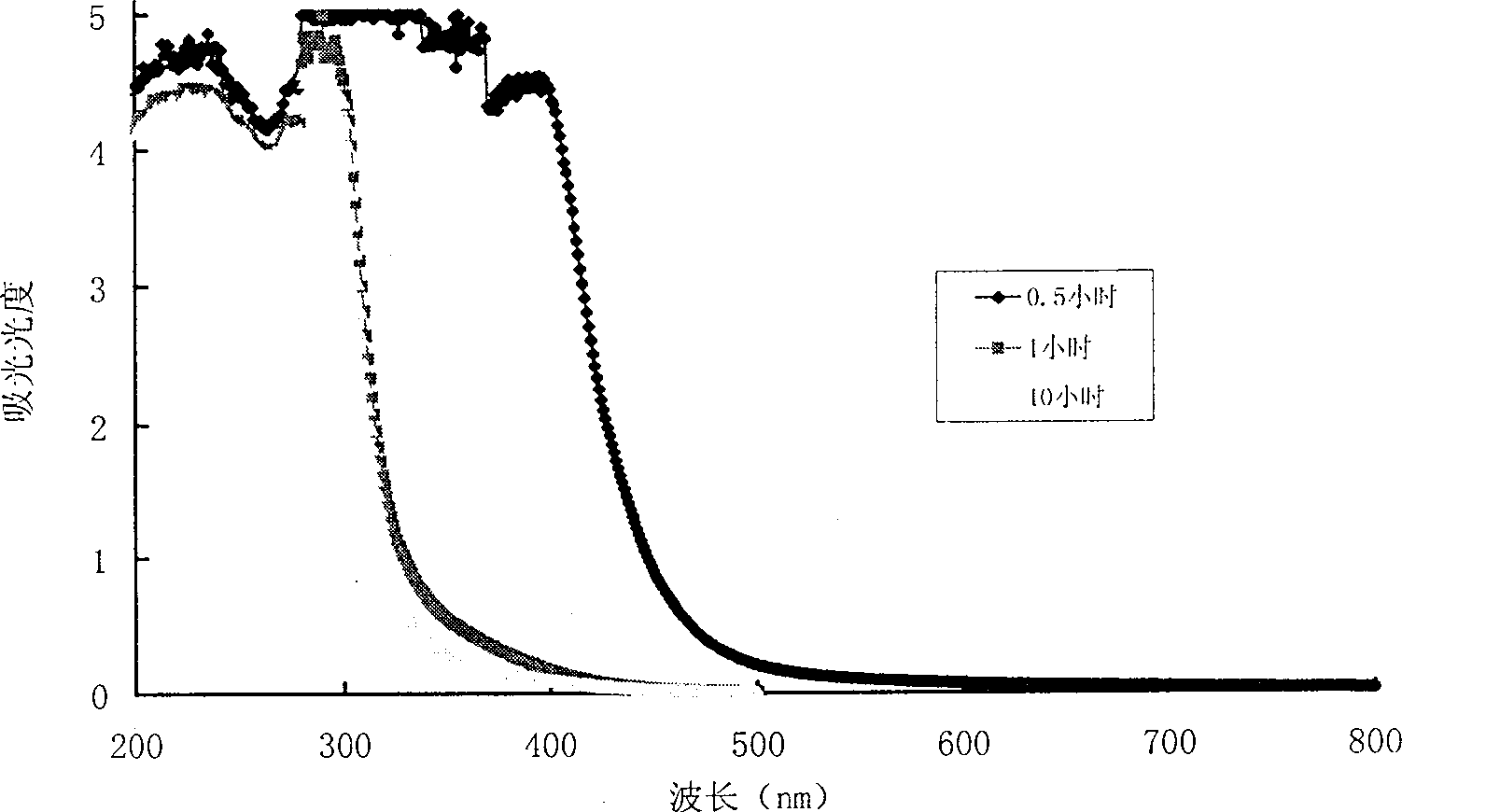

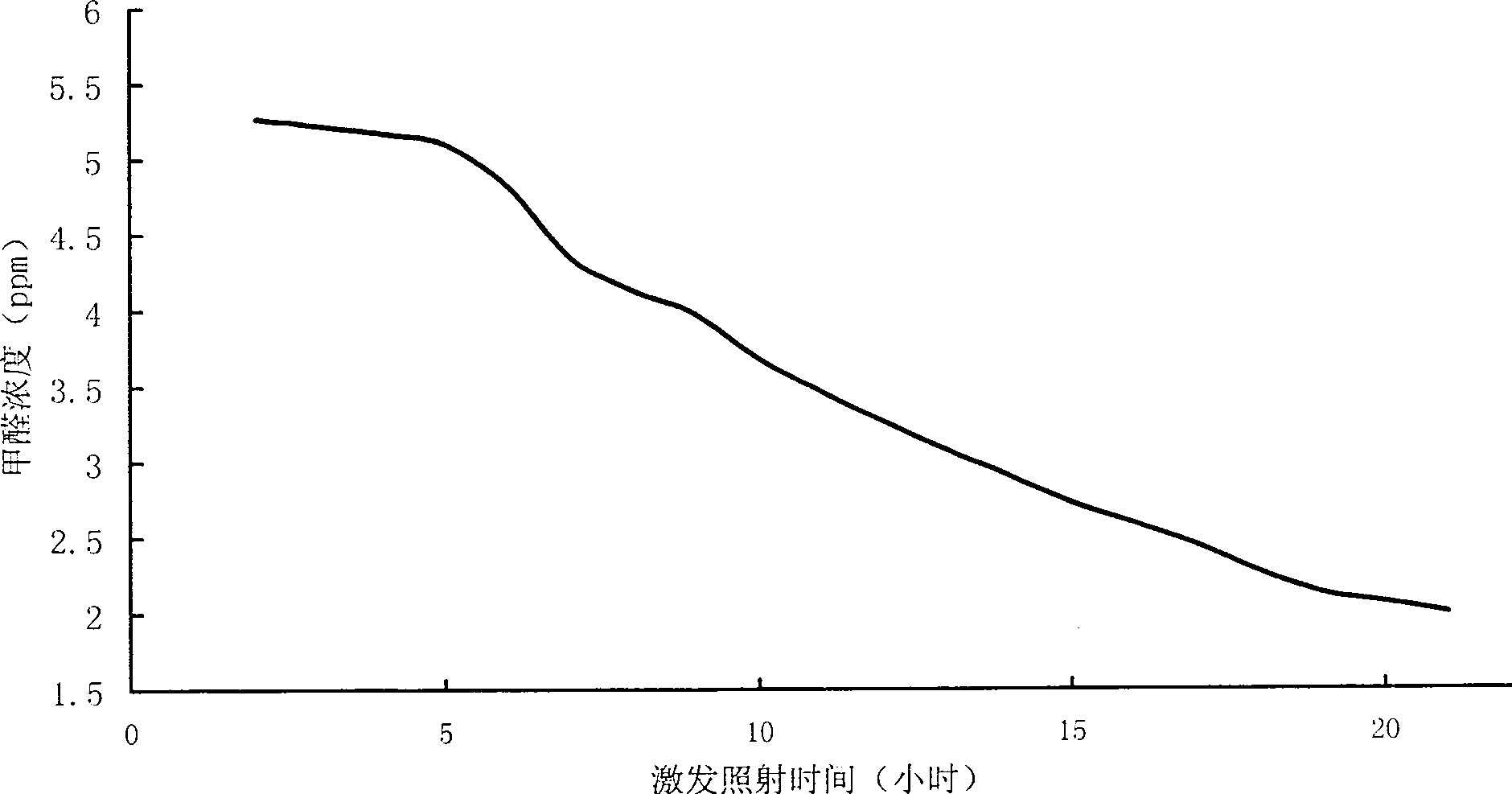

[0053] Sulfuric acid with a concentration of 80% by mass is heated to melt ilmenite (mass ratio is ilmenite: sulfuric acid = 1:2), and the obtained solid phase sediment is soaked in water to obtain titanium liquid, and the titanium liquid is filtered to remove insoluble substances , freeze and recrystallize to remove ferrous sulfate by filtration to obtain a titanium-containing solution, Ti 4+ The ion concentration is 0.1-0.2 mol / L; the pH value is adjusted to 7 with ammonia water, and orthotitanic acid is precipitated, washed to remove impurities. Take 100 g of orthotitanic acid precipitate, add 50 ml of distilled water, and then add 200 ml of neutral (pH value of 7) silica aqueous sol with a particle size of 8-20 nm. After mixing evenly, add 40ml of hydrogen peroxide solution with a mass percentage concentration of 30%, and reflux at 80°C for 0.5 hour, 1 hour, and 10 hours respectively to obtain different orange-yellow transparent titanium dioxide / silicon dioxide nano-compos...

Embodiment 3

[0055] 100g titanyl sulfate is dissolved in 500ml distilled water to form a titanium-containing solution, Ti 4+ The ion concentration is 0.1~0.3mol / L. Use 1mol / L NaOH solution to adjust the pH value to 7 to obtain orthotitanic acid precipitate, wash to remove impurities. Take 100g of orthotitanic acid precipitate and first add 40ml of hydrogen peroxide solution with a mass percentage concentration of 30%. After it is completely dissolved, adjust the pH value to 8 with dilute ammonia water, and then add 100ml of alkaline silica with a particle size of 8 to 20nm. The sol was refluxed at 90° C. for 6 hours to obtain a light yellow transparent titanium dioxide / silicon dioxide composite photocatalytic sol, and the particle diameter of the composite photocatalytic sol was 15-30 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com