Nanometer fluorocarbon modified coating with titania, its production and process

A technology of nano-titanium dioxide and modified fluorocarbon, applied in the direction of coating, etc., can solve the problems of poor stain resistance and scrub resistance, unsuitable for aluminum alloy profiles and plate surface coating, etc., to achieve easy control and good self-cleaning Performance, the effect of fewer steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

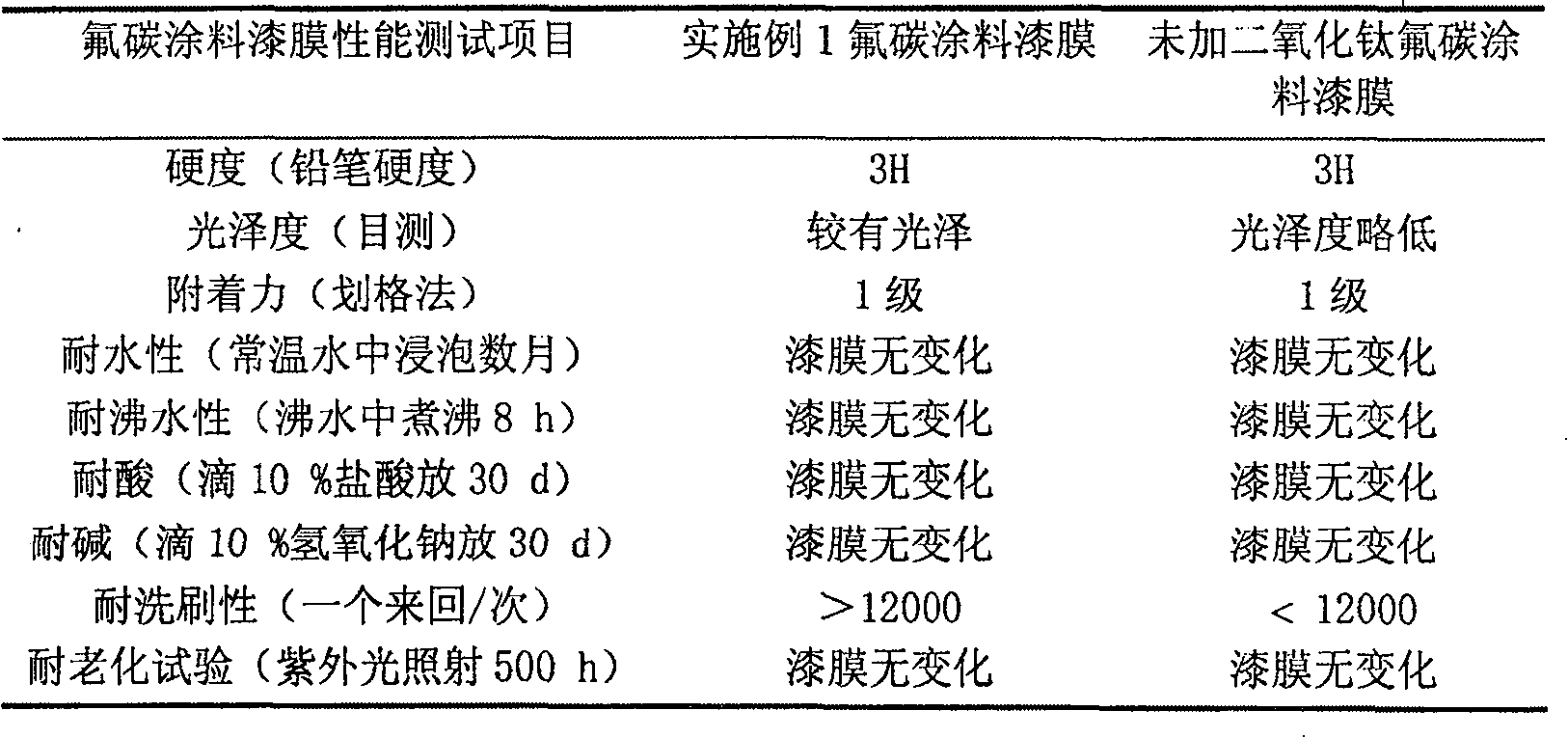

[0021] Embodiment 1 Nano-titanium dioxide modified fluorocarbon coating and its preparation example ①

[0022] The ratio of modified fluorocarbon coating in this example, anatase nano-TiO 2 and rutile nano-TiO 2 Mixture (the weight mixing ratio of the two is 4:1): fluorocarbon coating = 2:100. The anatase nano-TiO 2 and rutile nano-TiO 2 The mixture is available on the market.

[0023] The preparation method is as follows: (1) oleic acid coated anatase nano-TiO 2 and rutile nano-TiO 2 Preparation of the mixture Take 4g (2% of fluorocarbon coating) nano anatase TiO 2 and rutile TiO2 Pour the mixture powder into 50ml of deionized water, then add about 2ml of perchloric acid dropwise, and stir to make the water and powder mix evenly, adjust its pH value to 4, and then ultrasonically vibrate for 30 minutes; At the same time, add 3ml of oleic acid to the mixture first, then slowly add ammonia water dropwise, and at the same time stir rapidly to adjust the pH of the suspensio...

Embodiment 2

[0045] Embodiment 2 Nano-titanium dioxide modified fluorocarbon coating and its preparation example ②

[0046] The ratio of modified fluorocarbon coating in this example, anatase nano-TiO 2 and rutile nano-TiO 2 Mixture (the ratio of the two is 4:1): fluorocarbon coating = 3:100.

[0047] The preparation method is as follows: (1) oleic acid coated anatase nano-TiO 2 and rutile nano-TiO 2 Preparation of mixture to obtain anatase nano-TiO 2 and rutile nano-TiO 2 Pour 6g of the mixture powder into about 75ml of deionized water, then add 3ml of perchloric acid dropwise, and stir to mix the water and powder evenly, adjust the pH value to 4, and then ultrasonically vibrate for 35 minutes; Add 6ml of oleic acid to the mixture, then slowly add ammonia water dropwise, and at the same time stir rapidly to adjust the pH of the suspension to 8.5; heat the suspension to >90°C to slowly evaporate the water to obtain nano Titanium dioxide powder; (2) mixing the prepared oleic acid-coat...

Embodiment 3

[0049] Example 3 Example of pretreatment process of aluminum alloy plate

[0050] (1) Use a grinder for mechanical polishing to remove burrs, scale, adhered release agent, various oil stains, reduce surface roughness, and wash to remove slag; (2) Degreasing ①Ultrasonic degreasing solvent: acetone , temperature: room temperature, soaking time: 10min; ②Solvent used for solvent degreasing: trichlorethylene solvent, temperature: 60°C, soaking time: 8min; ③Used solution for alkaline cleaning and degreasing: containing sodium phosphate 20g dm -3 , sodium bicarbonate 20g·dm -3 , nonionic surfactant 8ml·L -1 , temperature: 60°C, soaking time: 3min; (3) Rust removal and oxidation film removal: the first pickling: use a solution containing 7.5% (volume ratio) of sulfuric acid, corrosion inhibitor urotropine (hexamethylene Tetramine) 0.5g·dm -3 , temperature: 40°C, soaking time: 3min; second pickling: use a solution containing 8% (volume ratio) nitric acid, temperature: 20°C, soaking ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com