Fischer-Tropsch synthesis method

A technology for Fischer-Tropsch synthesis and coal-to-synthesis gas, which is applied in the recovery of liquid hydrocarbon mixtures, petroleum industry, etc., can solve the problems of increasing the tail gas emission of the second-stage device, reducing the process economy, reducing the conversion rate, etc., and achieves improvement. The effect of distribution, improved utilization, and improved conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

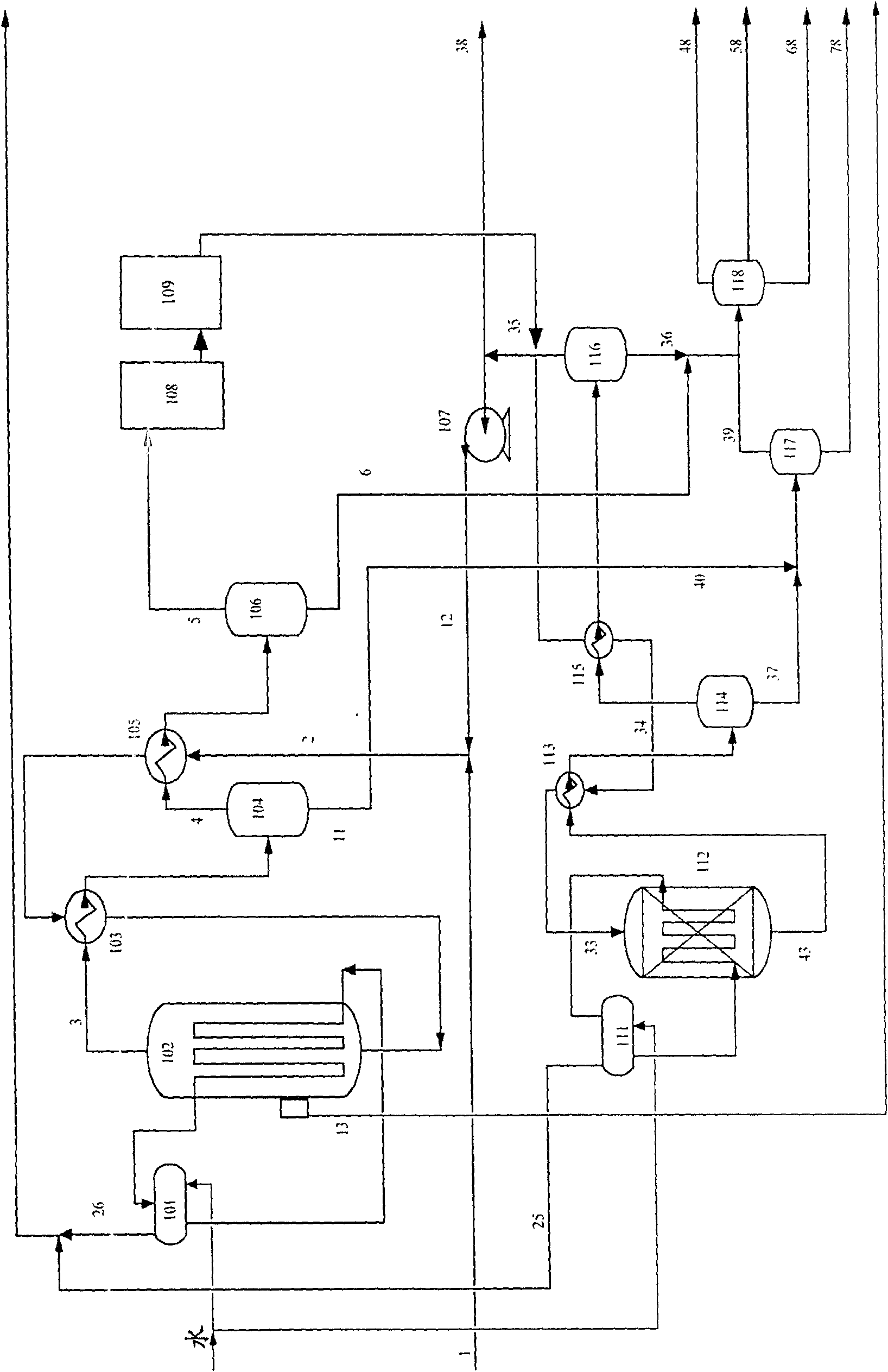

[0031] This embodiment adopts figure 1 In the process flow shown, the fresh raw material gas is coal gasified, then purified and water-gas shifted to obtain H 2 The synthesis gas with a / CO volume ratio of 1.5, the specific composition is shown in Table 1.

[0032] Table 1 Composition of raw materials for coal-based syngas

[0033] Composition, v%

[0034] The weight composition of the iron-based catalyst used in the primary reactor is 100Fe:5Cu:5K 2 O: 25SiO 2 . Its preparation method is to first mix ferric nitrate and copper nitrate solution in proportion to form a mixed solution, and then add Na 2 CO 3 The solution was precipitated, then filtered and washed free of alkali; the filter cake was beaten and excess K 2 SiO 3 , and join the HNO 3 Wash off excess potassium ions, wash and filter, beat the filter cake and spray dry to obtain catalyst particles with a particle size range of 60-90 microns. After the catalyst is reduced, it can be used as a qualified ...

Embodiment 2

[0047] This embodiment adopts figure 1 In the process flow shown, the fresh raw material gas is coal gasified, then purified and water-gas shifted to obtain H 2 The synthesis gas with a / CO volume ratio of 1.3, the specific composition is shown in Table 5.

[0048] Table 5 Composition of raw materials for coal-based syngas

[0049] Composition, weight %

[0050] The iron-based and cobalt-based catalysts used in the primary and secondary reactors are the same as in Example 1.

[0051] Fresh raw material gas and recycle gas are mixed according to the ratio of 2, and then reacted under the process conditions listed in Table 6. About 75% of CO+H 2 Converted in the first stage reactor. The tail gas of the primary reactor is deCOated by potassium carbonate 2 After treatment, the C1-C4 hydrocarbons are converted by the methane autothermal oxidation device, and the treated tail gas enters the second-stage reactor, and reacts under the process conditions listed in Table 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com