A producing method of food-level concentrated soybean phospholipid

A technology of soybean concentrated phospholipid and production method, which is applied in the directions of edible phospholipid composition, food preparation, protein food ingredients, etc., can solve the problems of insufficient mechanical strength, acid and alkali resistance, easy clogging, etc., and achieves good transparency and light color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

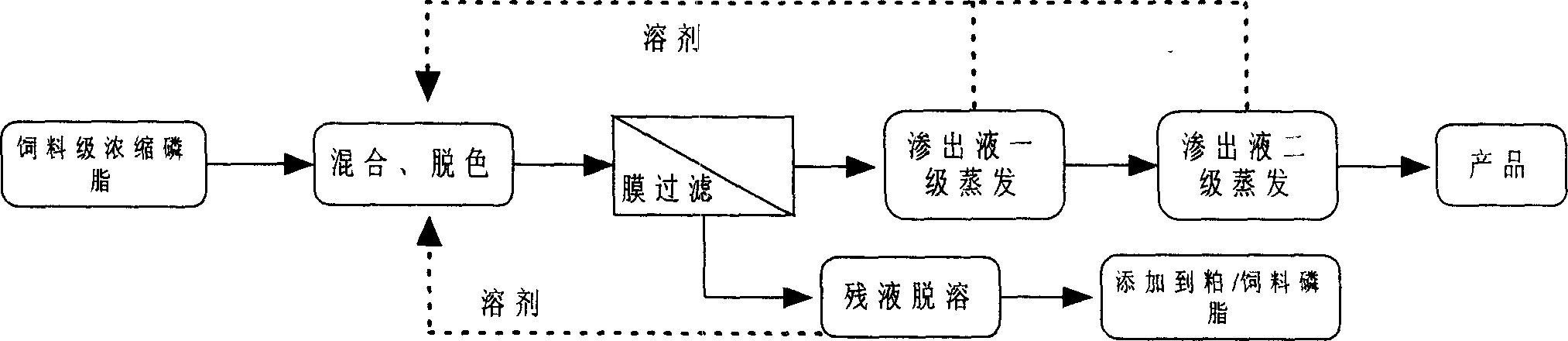

Method used

Image

Examples

Embodiment 1

[0015] Feed-grade soybean concentrated phospholipids are used as raw materials and dissolved with n-hexane. The mass ratio of raw materials and solvents is optimal for the raw material dissolution process. During the decolorization process, hydrogen peroxide with 1.5% of the feed-grade soybean concentrated phospholipid mass is added and stirred at 40°C for decolorization. For 40 minutes, choose 200nm membrane tube, the temperature is 35 ℃, the filter treatment effect is best under the pressure before the tube 0.15MPa, the primary evaporation condition is 60 ℃, the residual pressure is 0.18kPa, the secondary evaporation temperature is 75 ℃, the residual pressure 0.18kPa, the acetone insoluble matter of the obtained product is greater than 62%, the ether insoluble matter is less than 0.2%, the Gardner color is 11+, the volatile matter is less than 50mg / kg, and the product has good transparency.

Embodiment 2

[0017] Feed-grade soybean concentrated phospholipids are used as raw materials and dissolved in petroleum ether. The mass ratio of raw materials and solvents is 1:2 in the raw material dissolution process. During the decolorization process, hydrogen peroxide with 1% of the feed-grade soybean concentrated phospholipid mass is added, and stirred at 60 ° C for 20 minutes to decolorize , select 50nm membrane tube, filter at 50°C and 0.3MPa in front of the tube, the primary evaporation condition is 50°C, the residual pressure is 0.18kPa, the secondary evaporation temperature is 60°C, and the residual pressure is 0.18kPa, the product is obtained The acetone insoluble matter is greater than 62%, the ether insoluble matter is less than 0.2%, the Gardner color is 11+, the volatile matter is less than 50mg / kg, and the product has good transparency.

Embodiment 3

[0019] Feed-grade soybean concentrated phospholipids are used as raw materials and dissolved with n-hexane. The mass ratio of raw materials and solvents used in the raw material dissolution process is 1:6. During the decolorization process, 4% hydrogen peroxide is added to feed-grade soybean concentrated phospholipids, and stirred at 20 ° C for 60 minutes. , using a 500nm membrane tube, the temperature is 20°C, the pressure before the tube is 0.05MPa, and the filtration treatment is carried out. The primary evaporation condition is 70°C, the residual pressure is 0.18kPa, the secondary evaporation temperature is 90°C, and the residual pressure is 0.18kPa. The product is obtained The acetone insoluble matter is greater than 62%, the ether insoluble matter is less than 0.2%, the Gardner color is 11+, the volatile matter is less than 50mg / kg, and the product has good transparency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com