Lithium cell positive material thiofuran polymer and lithium battery preparation method

A positive electrode material, lithium battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low specific capacity and low energy density, and achieve high energy density, high specific capacity and energy density, and good cycle stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

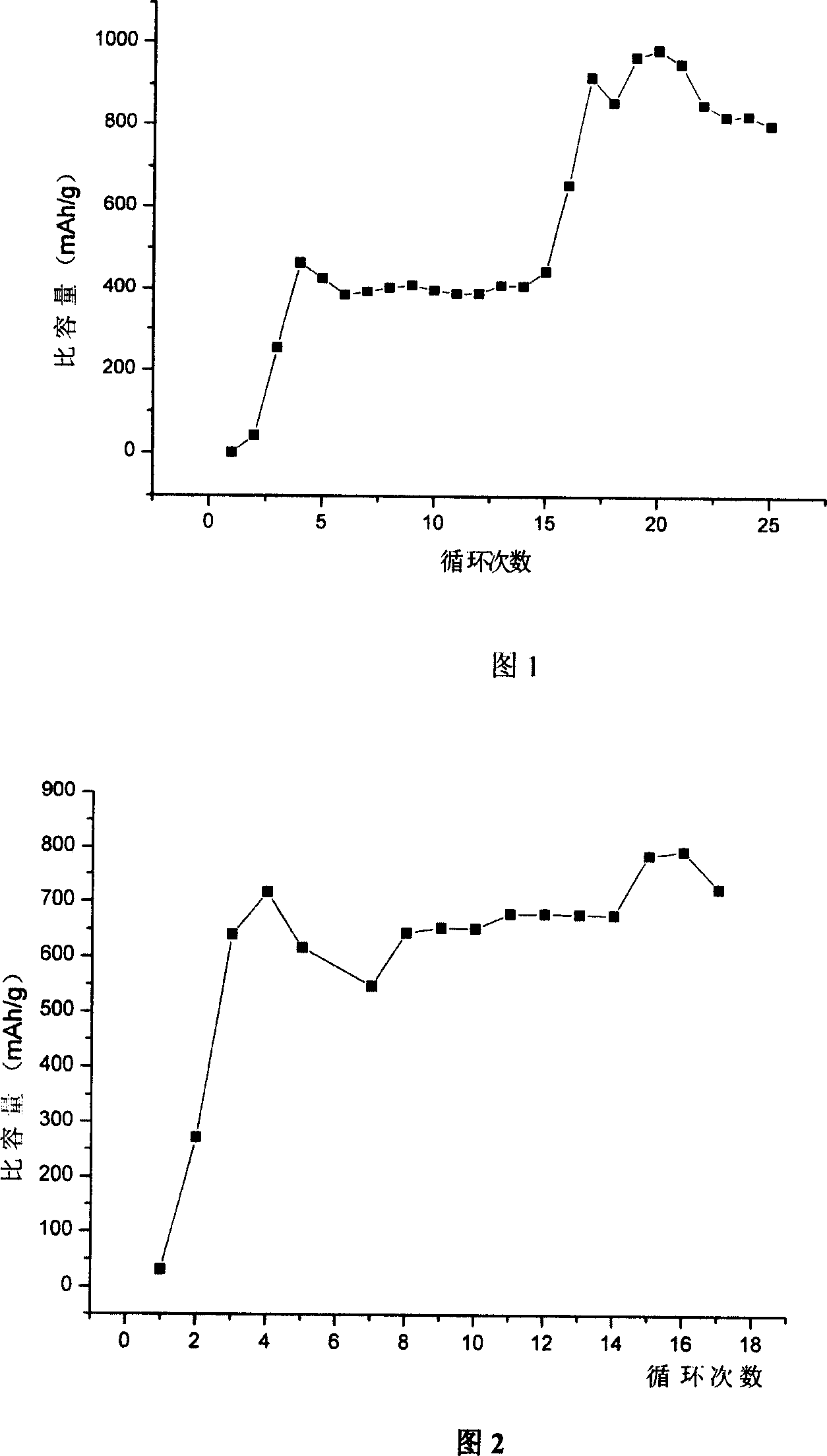

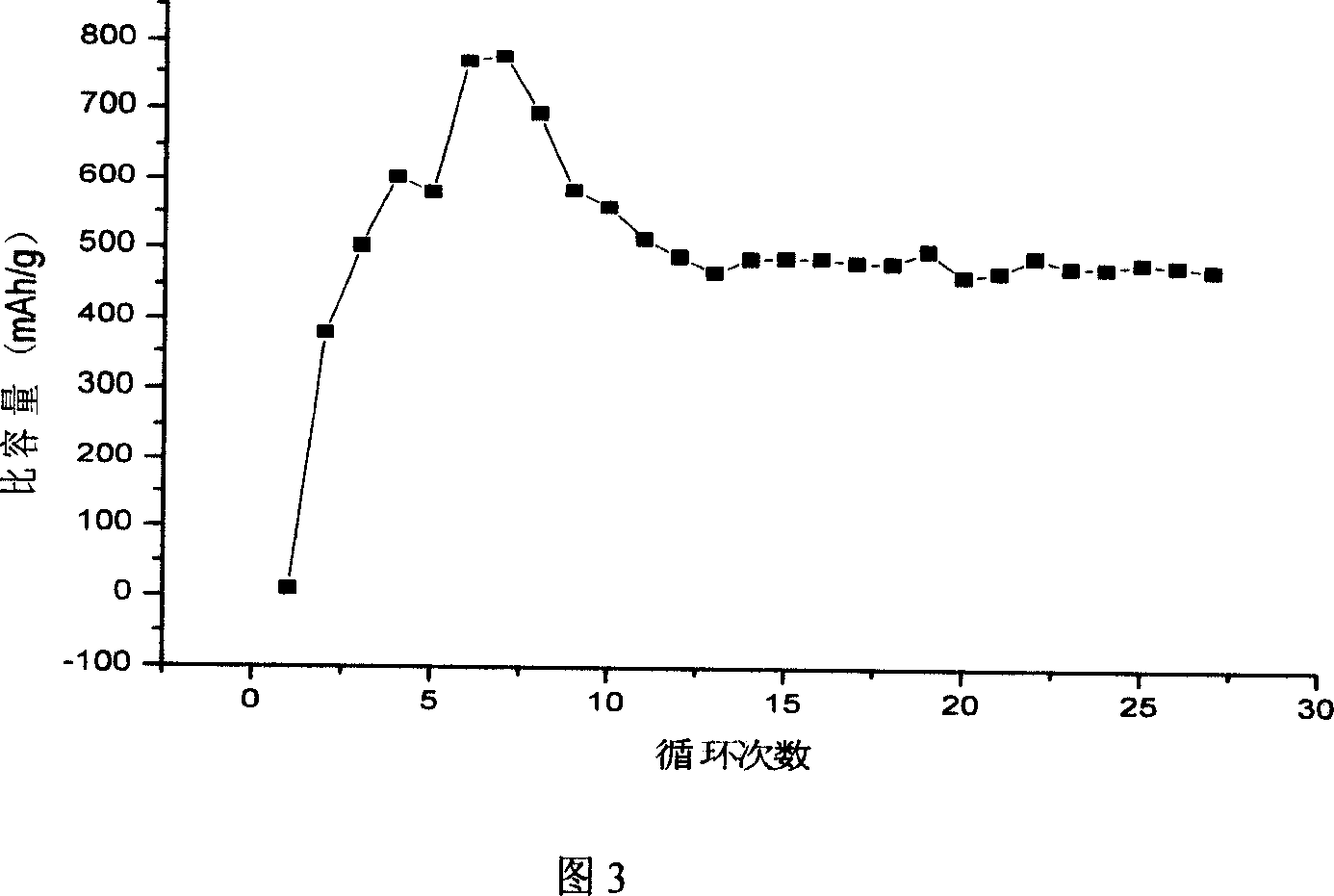

Examples

Embodiment 1

[0038] Put 0.84g of thiophene and 3.25g of ferric chloride in a mortar and grind at room temperature for about 30 minutes until no HCl gas is released, then stop grinding. Add 50 milliliters of dehydrated ethanol in the beaker, transfer the solid in the mortar to the beaker, stir it electromagnetically for 10 minutes, filter and dry; repeat washing the solid 3 times until the effluent when filtering is colorless. After drying, the product was transferred to a filter paper tube and placed in a Soxhlet extractor. 100 milliliters of dehydrated ethanol is loaded into a 250 milliliter single-necked flask, a Soxhlet extractor is installed, and the above-mentioned crude product is put into the extractor and extracted for two days until the effluent liquid is a colorless and transparent liquid. The product was taken out and dried, weighed 0.75 g, and the yield was 89%.

[0039] Add 50 milliliters of chloroform in a 100 milliliter flask equipped with a reflux condenser, and dissolve 0...

Embodiment 2

[0042] Weigh 0.84g of thiophene, 3.2g of anhydrous ferric chloride, 2.7g of ferric chloride hexahydrate, add them to the mortar, and grind for about 30 minutes under the condition of ice-salt bath (-10°C) until there is no HCl gas Release, stop grinding.

[0043] Add 50 milliliters of absolute ethanol into a beaker, pour the solid in the mortar into the beaker, and stir with electromagnetic for 10 minutes. Filter and dry. The solid was washed repeatedly with 50 ml of absolute ethanol until the effluent was colorless upon filtration. After the crude product is dried, it is transferred to a filter paper tube and placed in a Soxhlet extractor. 100 milliliters of dehydrated ethanol is loaded into a 250 milliliter single-necked flask, a Soxhlet extractor is installed, and the above-mentioned crude product is put into the extractor and extracted for two days until the effluent liquid is a colorless and transparent liquid. The product was dried and weighed 0.73 g, yield 86%.

[0...

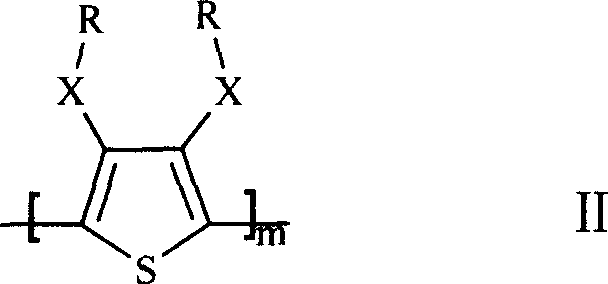

Embodiment 3

[0047] Put 0.84g of thiophene and 6.5g of ferric chloride in a mortar, grind for about 30 minutes at a temperature of 4-10°C, stop grinding until no HCl gas is released. Wash the solid with 50 ml of absolute ethanol, add 50 ml of absolute ethanol to a beaker, pour the solid in the mortar into the beaker, and stir for 10 minutes. Filter and dry. The solid was washed with 50 ml of absolute ethanol until the effluent was colorless when filtered. After the crude product is dried, it is transferred to a filter paper tube and placed in a Soxhlet extractor. Put 100 milliliters of absolute ethanol into a 250 milliliter single-necked flask, install a Soxhlet extractor, extract iron in the polymer with ethanol, and extract for two days until the liquid that flows out is a colorless and transparent liquid.

[0048] Dried, weighed 0.76 g, yield 90%.

[0049] Add 50 milliliters of chloroform in a 100 milliliter flask equipped with a reflux condenser, and dissolve 0.76 g of polymer in ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com