Epoxy acrylic resin and preparing method thereof

An epoxy acrylic and epoxy resin technology, applied in epoxy resin coatings, modified epoxy resin adhesives, coatings, etc., can solve the problems of high brittleness, high rigidity, low elongation, etc., and achieve improved flexibility , The effect of improving wettability and increasing heat distortion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

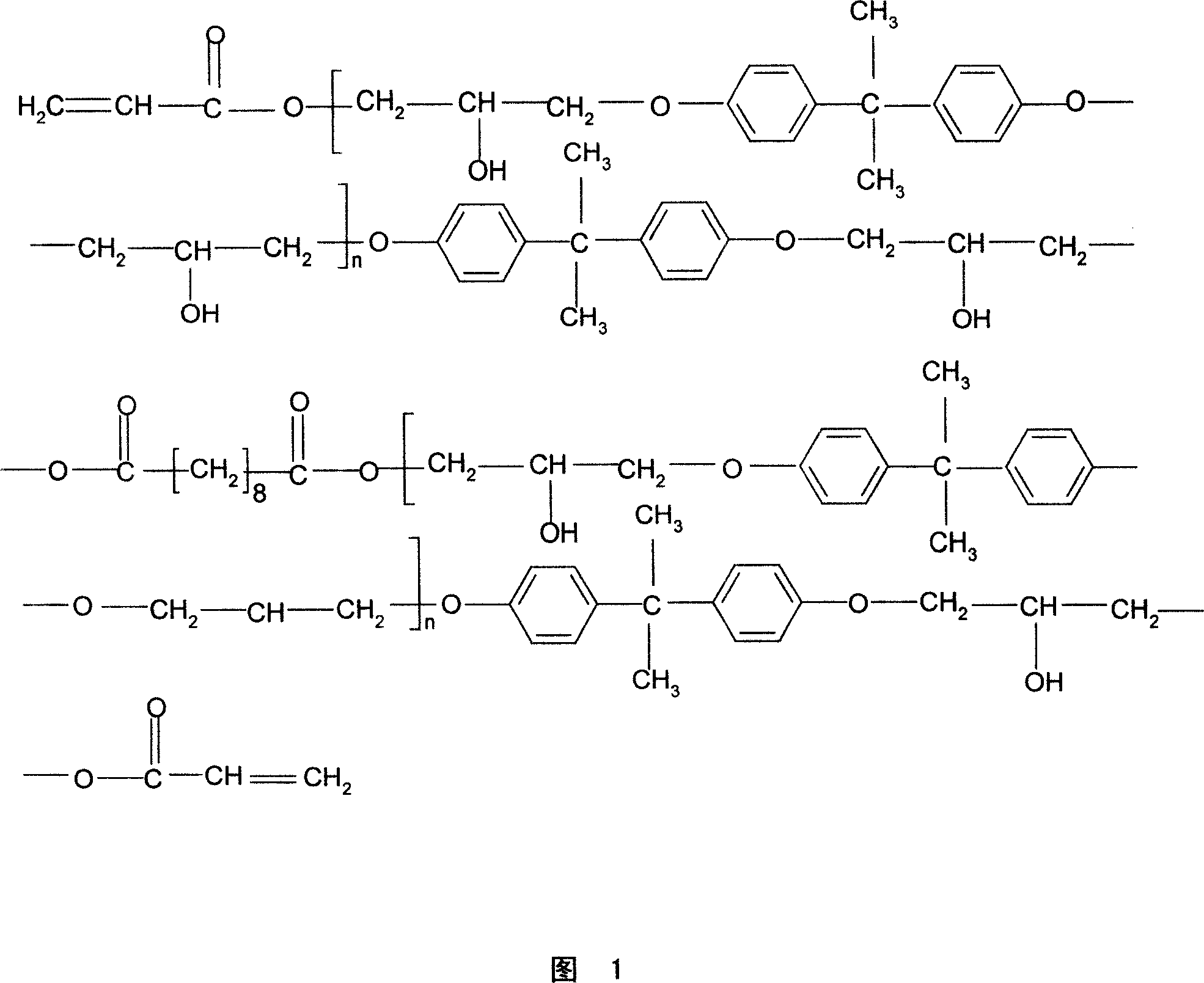

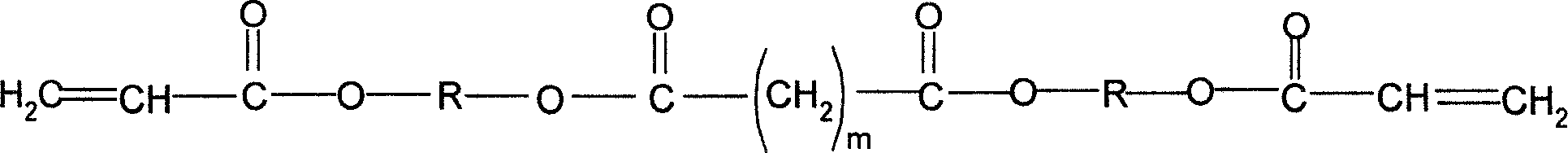

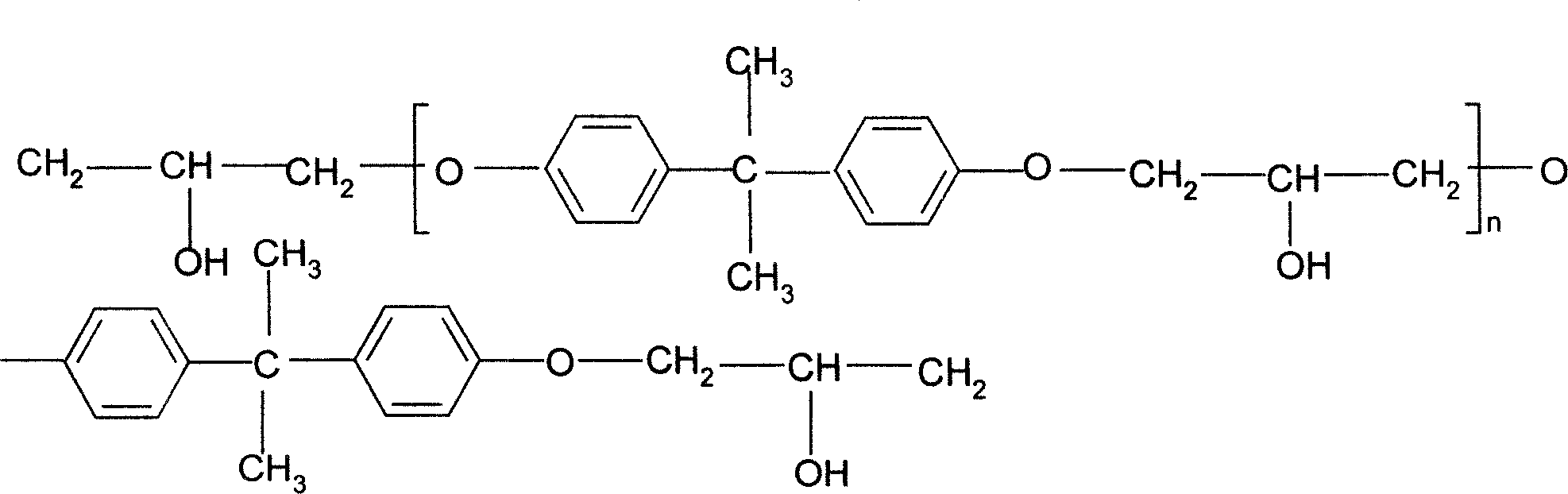

[0027] The preparation of the epoxy acrylic resin of embodiment 1 adipic acid modification

[0028] Add 70 parts of epoxy resin E-51 (618) into a reaction kettle equipped with a stirrer, a thermometer and a dropping funnel, and add 12 parts of adipic acid with a dropping funnel when slowly heating to 60°C with an oil bath, and control it at Dropping is completed within 20 minutes, and then 0.5 parts of triphenyl antimony is added after the addition. Stop heating when the temperature rises to 80°C while stirring, and start to cool down when the system temperature rises to 100°C, and keep the system temperature between 80°C and 115°C for 1.5 hours. Use GB2895-82 to measure the acid value of the system. When the acid value is less than 5, add 15 parts of acrylic acid, and then add 1.8 parts of p-methoxyphenol and 0.7 parts of triphenyl antimony. After reacting at 115°C to 120°C for 2 hours, take a sample to measure the acid value, and when the acid value is less than 3, cool dow...

Embodiment 2

[0029] The preparation of the epoxy acrylic resin of embodiment 2 pimelic acid modification

[0030] Add 57 parts of epoxy resin E-44 (601) into the reaction kettle equipped with stirrer, thermometer and dropping funnel, and add 21 parts of pimelic acid with the dropping funnel when slowly heating to 60°C with an oil bath, and control it at The drop was completed within 30 minutes, and after the addition was completed, 11.5 parts of a mixture of N,N-dimethylbenzylamine and triphenylarsine were added. Stop heating when the temperature rises to 80°C while stirring, and start to cool down when the system temperature rises to 100°C, and keep the system temperature between 80°C and 115°C for 2 hours. Use GB2895-82 to measure the acid value of the system. When the acid value is less than 5, add 17 parts of acrylic acid, and then add 2.5 parts of hydroquinone and 1.0 parts of N, N-dimethylbenzylamine and triphenylarsine mixture. After reacting at 115°C to 120°C for 2.5 hours, take ...

Embodiment 3

[0031] The preparation of the epoxy acrylic resin of embodiment 3 azelaic acid modification

[0032]Add 64 parts of epoxy resin E-51 (618) into the reaction kettle equipped with stirrer, thermometer and dropping funnel, and add 16 parts of azelaic acid with the dropping funnel when slowly heating to 60°C with an oil bath, and control it at After the addition was completed within 15 minutes, 0.3 parts of a mixture of tetra-n-butylammonium bromide and triphenylantimony was added. Stop heating when the temperature rises to 80°C while stirring, and start to cool down when the system temperature rises to 100°C, and keep the system temperature between 80°C and 115°C for 2.5 hours. Use GB2895-82 to measure the acid value of the system. When the acid value is less than 5, add 18 parts of acrylic acid, and then add 1.0 parts of 1,4-naphthalenediol and 0.7 parts of tetra-n-butylammonium bromide and triphenyl antimony mixture. After reacting at 115°C to 120°C for 2.0 hours, take a samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com