Method of preparing cyanamide aqueous solution and dicyandiamide and coproducing carbon and calcium carbonate by calcium cyanamide

A technology of cyanamide and aqueous solution, applied in calcium carbonate/strontium/barium, organic chemistry, etc., can solve the problem that dicyandiamide is difficult to deal with industrial waste residues, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

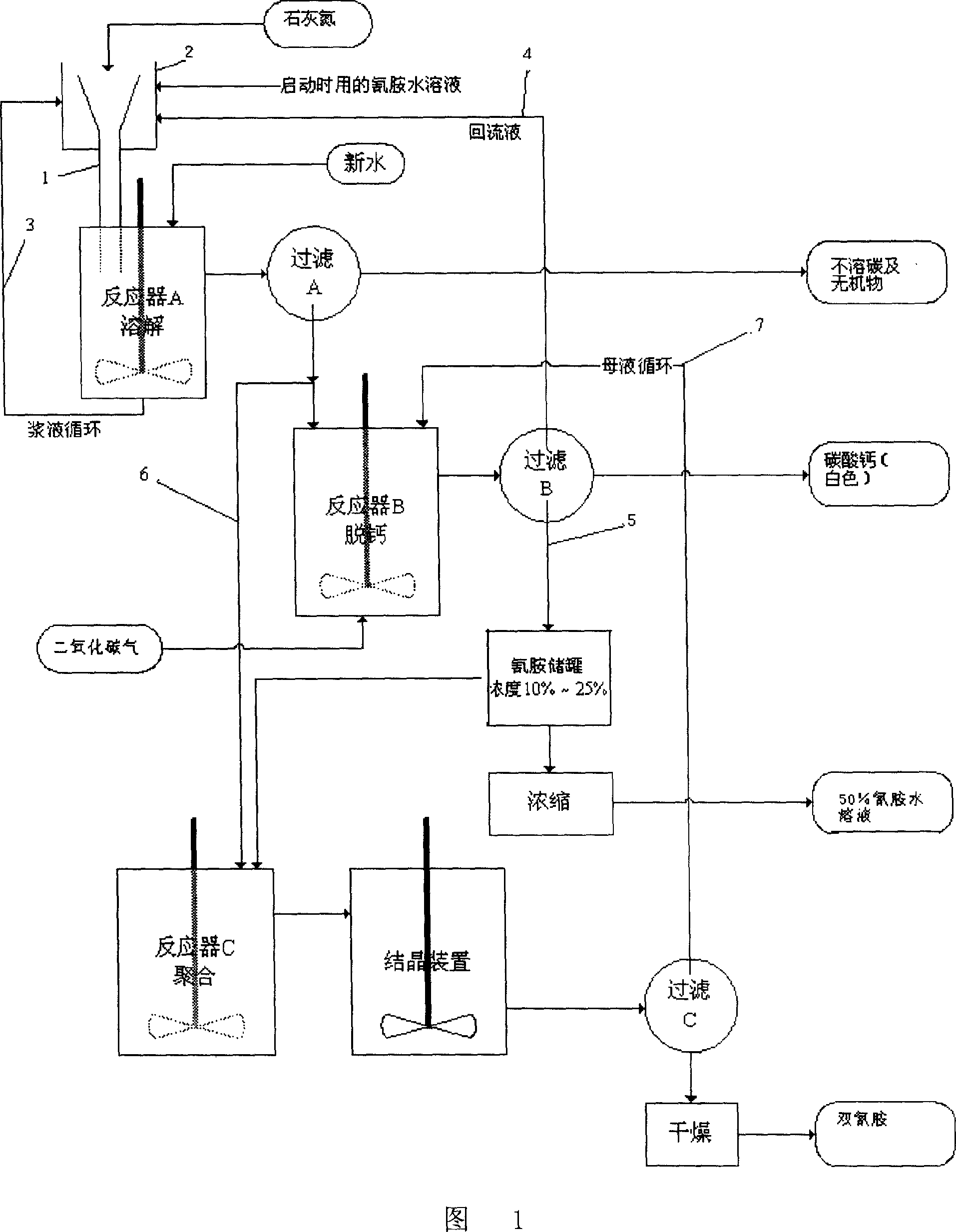

Image

Examples

Embodiment 1

[0075] Example 1 Using 5% aqueous cyanamide solution, batch hydrolysis example

[0076] Into the 500mL beaker equipped with stirring, add 200g (pH7.5) of 5.00% cyanamide aqueous solution, and cool outside the beaker. Under the condition of stirring, add 10g of lime nitrogen at one time. The temperature in the beaker was kept below 20°C. After 10 minutes, the stirring was stopped, and the resultant was vacuum filtered with a Buchner funnel covered with filter paper with a diameter of 10 cm. The insoluble matter on the filter paper was washed with a small amount of water, and the filtrates were combined.

[0077] The main component of the remaining insoluble matter on the filter paper is carbon, weighing 2.83g, containing 30% water, and containing 0.17% available nitrogen. The black matter on the filter paper was first treated with 5% sodium hydroxide, then washed with water, treated with 5% nitric acid, washed with water, refined and dried to obtain 1.17 g of black carbon co...

Embodiment 2

[0103] Embodiment 2 uses the cyanamide aqueous solution of embodiment 1 gained, carries out batch hydrolysis example

[0104] Use the cyandiamide aqueous solution of example 1 gained, according to the same operating method of embodiment 2, final available cyanamide concentration 6.57%, the solution 220g of dicyandiamide concentration 0.65%. Using the material balance calculation method of Example 1 above, the dissolution efficiency is 98.0%.

[0105] Implementing this batch operation method cyclically can obtain a higher concentration of cyanamide aqueous solution.

Embodiment 3

[0106] Embodiment 3 uses 25% cyanamide aqueous solution, batch production cyanamide aqueous solution, dicyandiamide, co-production carbon and calcium carbonate

[0107] Add 200Kg of 25.00% cyanamide aqueous solution (pH10) to the 500L reactor equipped with stirring, circulate the normal temperature water outside the reactor for cooling, and add 25Kg of lime nitrogen at one time while stirring. The temperature in the kettle is kept below 40°C, and the cyanamide of the reaction solution is extracted at intervals to judge whether the reaction is complete. After about 30 minutes, the stirring is stopped, and the obtained product is transported to the drum filter, and the black insoluble matter is washed with a small amount of water. Combine the filtrates.

[0108] The main component of the insoluble matter is carbon. After acid-base refining and drying, 235Kg of black carbon components are obtained.

[0109] Lead the filtrate (mainly acidic calcium cyanamide aqueous solution) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com