Organic electroluminescent white light device with multi-luminescent layer

A white light device and organic light-emitting layer technology, applied in the field of organic electroluminescent devices, can solve the problems of poor anthracene film formation, high voltage, easy breakdown, etc., and achieve the effects of improving efficiency, performance, and device brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

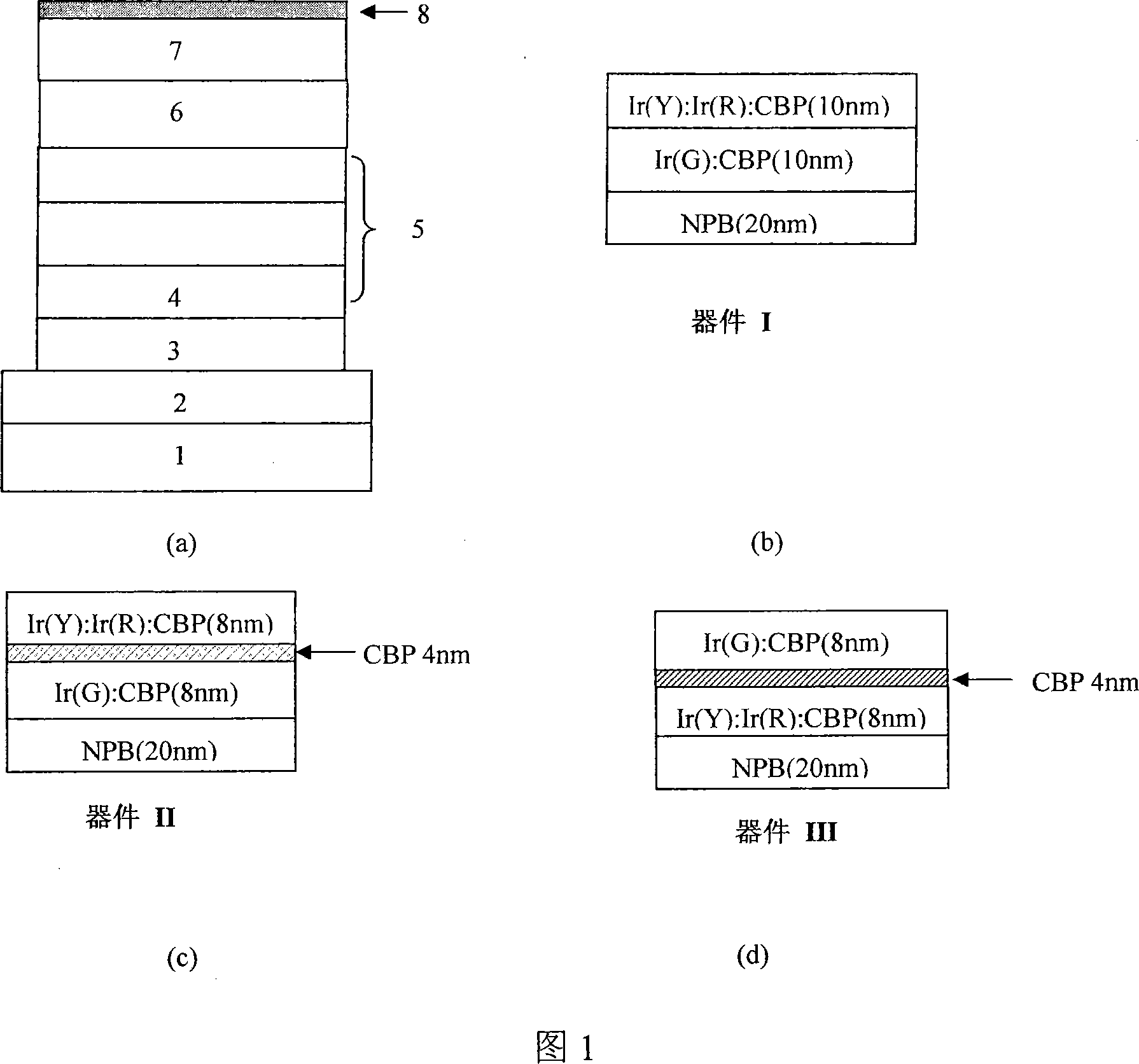

Embodiment 1

[0038] (1) To transparent conductive substrate ITO glass, carry out acetone, ethanol, deionized water to scrub successively, then carry out acetone, ethanol, deionized water ultrasonic cleaning to it again successively, carry out ultraviolet ozone treatment to it after drying;

[0039] (2) Place the above-mentioned pretreated ITO glass in the vacuum chamber of the evaporation equipment, and evacuate to 3×10 -4 Within Pa, evaporate 30nm m-MTDATA on the ITO film as a hole injection layer, and the evaporation rate is 0.1-0.2nm / s;

[0040] (3) Keeping the pressure in the above vacuum chamber constant, first evaporate a 20nm NPB layer as a hole transport layer and a blue light-emitting layer, and then evaporate a 10nm doped Ir(ppy) layer 3 A CBP layer with a concentration of 8wt% is used as a green light-emitting layer; finally, 10nm is evaporated and doped with 5wt% (F-BT) 2 Ir(acac) and 3wt% Ir(piq) 2 The CBP layer of acac is used as the yellow and red light-emitting layers;

...

Embodiment 2

[0046] (1) with embodiment 1;

[0047] (2) with embodiment 1;

[0048] (3) Keep the pressure in the above vacuum chamber constant, first evaporate a 20nm NPB layer as a hole transport layer and a blue light-emitting layer; sequentially evaporate 8nm doped Ir(ppy) 3 The CBP layer with a concentration of 8wt% is used as the green light-emitting layer; a 4nm non-doped CBP layer is evaporated to block the triplet energy transfer from the green dye to the yellow and red dyes; 5wt% (F-BT) 2 Ir(acac) and 3wt%Ir(piq) 2 The CBP layer of acac is used as the yellow light and red light emitting layers. The evaporation speed of these two layers is the same as that in Example 1, and the evaporation time is 40-80s;

[0049] (4) with embodiment 1;

[0050] (5) with embodiment 1;

[0051] (6) Same as in Example 1, to prepare device II.

Embodiment 3

[0053] (1) with embodiment 1;

[0054] (2) with embodiment 1;

[0055] (3) Keep the pressure in the above-mentioned vacuum chamber constant, first evaporate a 20nm NPB layer as a hole transport layer and a blue light-emitting layer; 2 Ir(acac) and 3 wt% Ir(piq) 2 The CBP layer of acac is used as the yellow and red light-emitting layer; then a 4nm non-doped CBP layer is evaporated to block the triplet energy transfer from the green dye to the yellow and red dyes; finally, the 8nm doped layer is evaporated Ir(ppy) 3 Concentration is the CBP layer of 8wt% as green light-emitting layer, and evaporation speed and evaporation time are the same as embodiment 2;

[0056] (4) with embodiment 1;

[0057] (5) with embodiment 1;

[0058] (6) Same as Example 1, prepare device III.

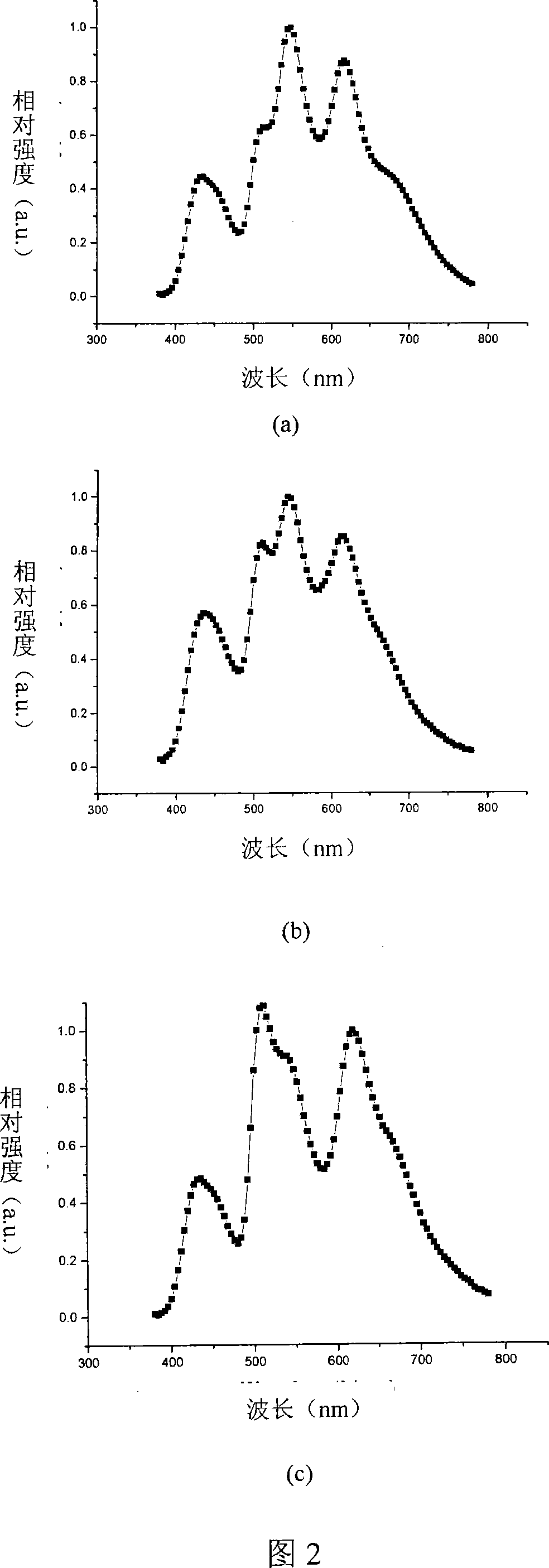

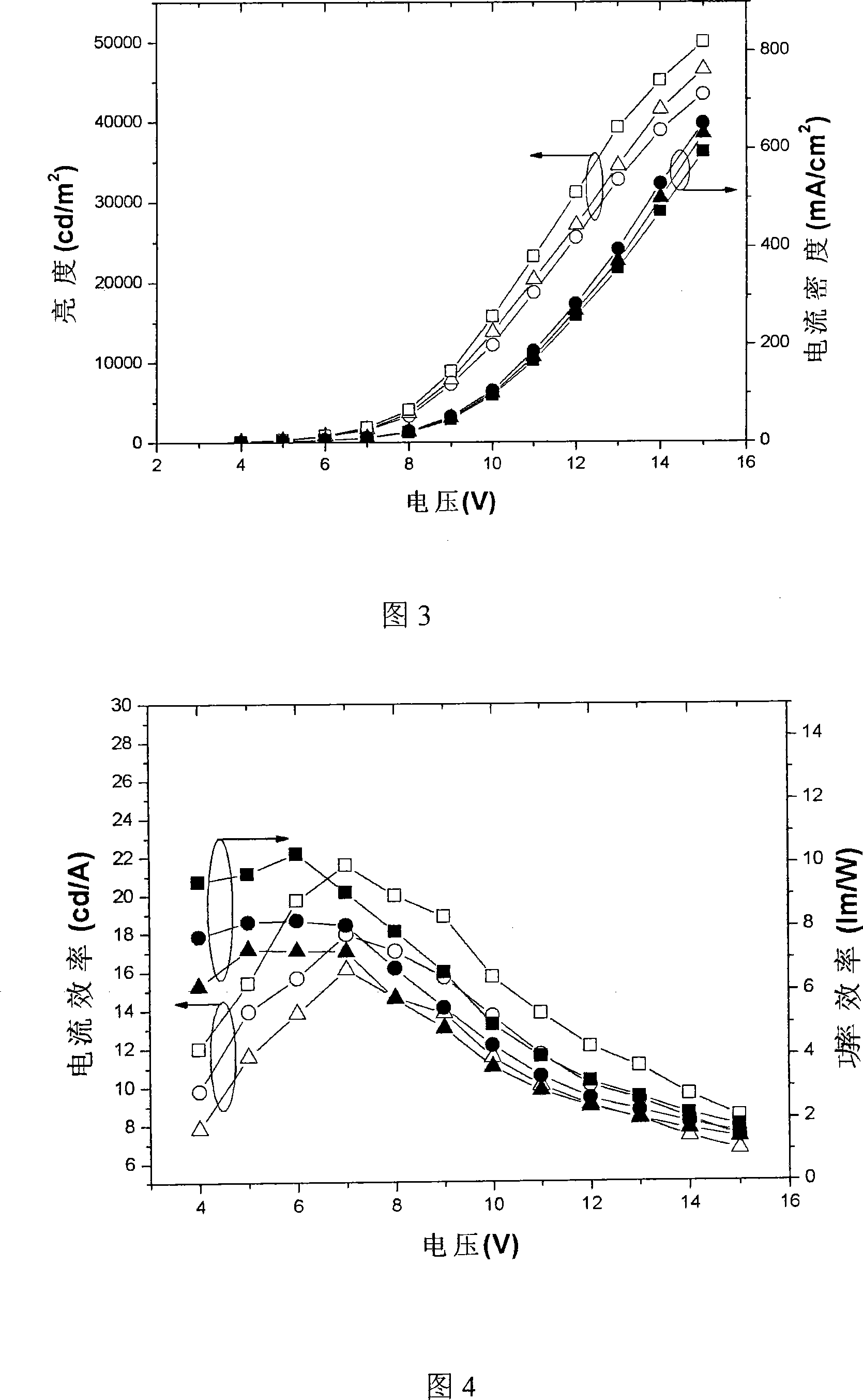

[0059] The electroluminescence spectrum of the device prepared in Examples 1-3 at a driving voltage of 7V is shown in Figure 2, the brightness-voltage, current density-voltage curves of the device are sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com