NOx reduction compositions for use in FCC processes

A technology of composition and mixture, applied in the direction of chemical/physical process, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems that have not been paid attention to, and achieve partial or incomplete improvement Effect of burning FCC process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] While the present invention is not limited to any particular method of preparation, compositions of the present invention are typically prepared by impregnating a microspheroidal particulate base material composition comprising components (i)-(iii) with a source of noble metal. The base material composition may be prepared using any conventional method, see, for example, US Patent Nos. 6,280,607; The carrier is used to prepare the base material composition containing components (i)-(iii).

[0054] In one embodiment of the invention, an aqueous slurry containing an amount of a peptized acidic metal oxide, such as peptized alumina, and an oxygen storage transition metal and / or rare earth metal salt, such as carbon, may be mixed, preferably stirred. salts, nitrates, sulfates, chloride salts, etc. to prepare the base material composition, the amount of peptized acidic metal oxide is sufficient to provide at least 1.0 wt%, preferably at least 25 wt%, most preferably at least...

specific Embodiment approach

[0072] Compositions of the present invention were evaluated in examples using a regenerator test unit (RTU) and model reactions for reduction of NO from FCCU regenerators operating in partial or incomplete combustion mode X And / or the effect of gas phase reduction nitrogen species. RTU is a device specially designed to simulate the operation of FCCU regeneration furnace. In G. Yaluris and A.W. Peters "Studying the Chemistry of the FCCU Regenerator Under Realistic Conditions", Designing Transportation Fuels for a Cleaner Environment, J.G. Reynolds RTUs are described in detail in M.R. Khan, Ed., p. 151, Taylor & Francis, 1999, ISBN: 1-56032-813-4, which description is incorporated herein by reference.

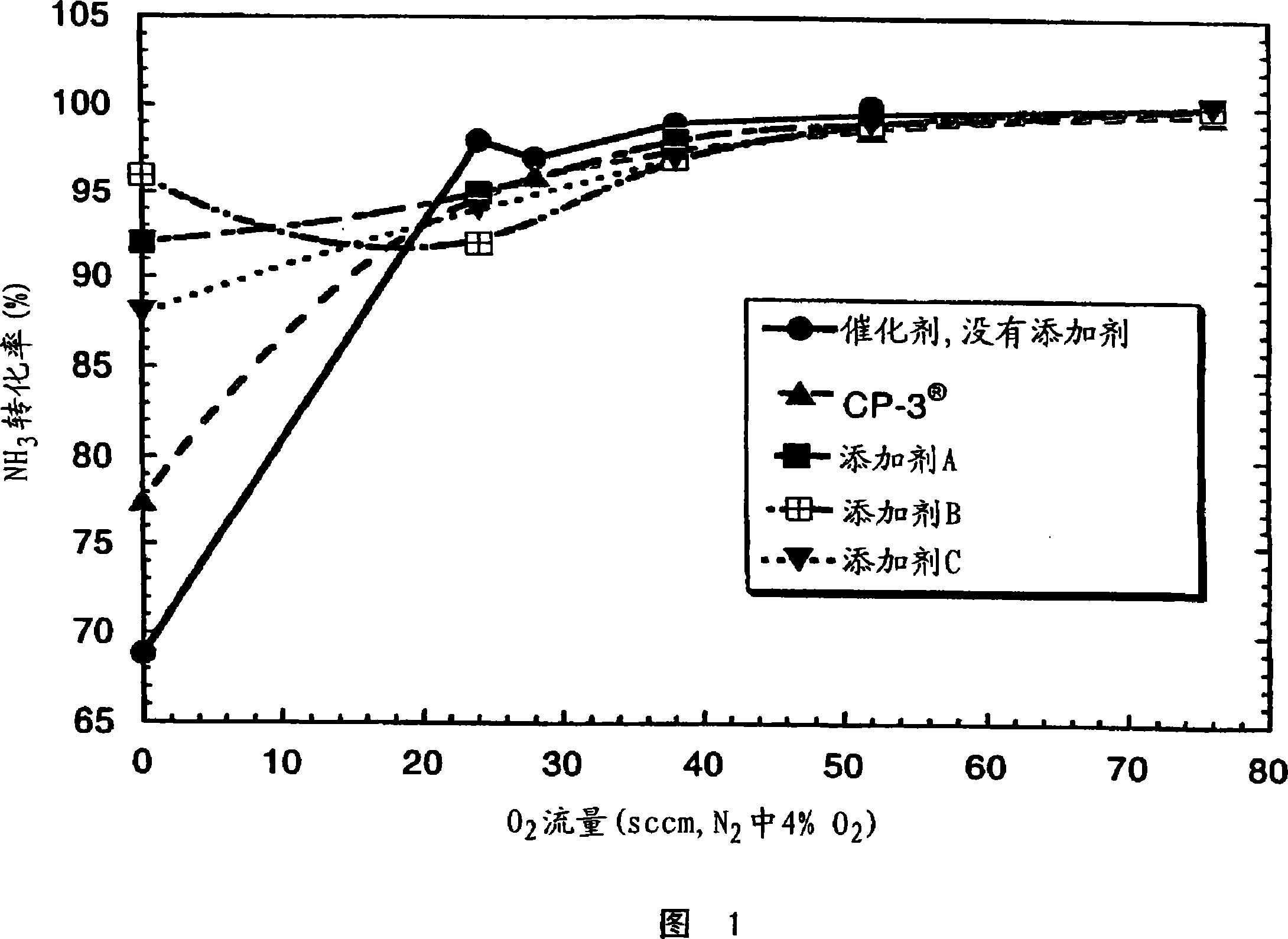

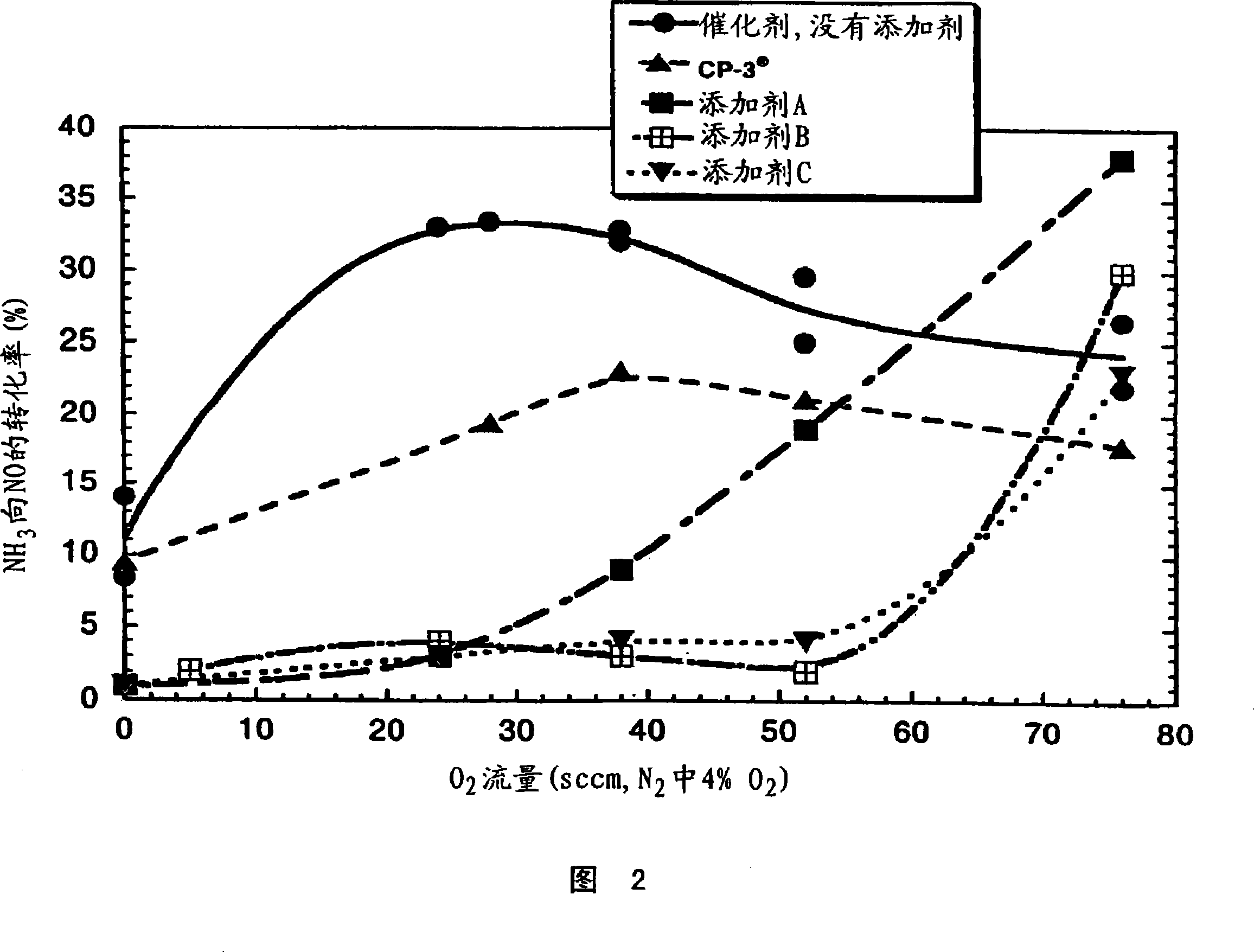

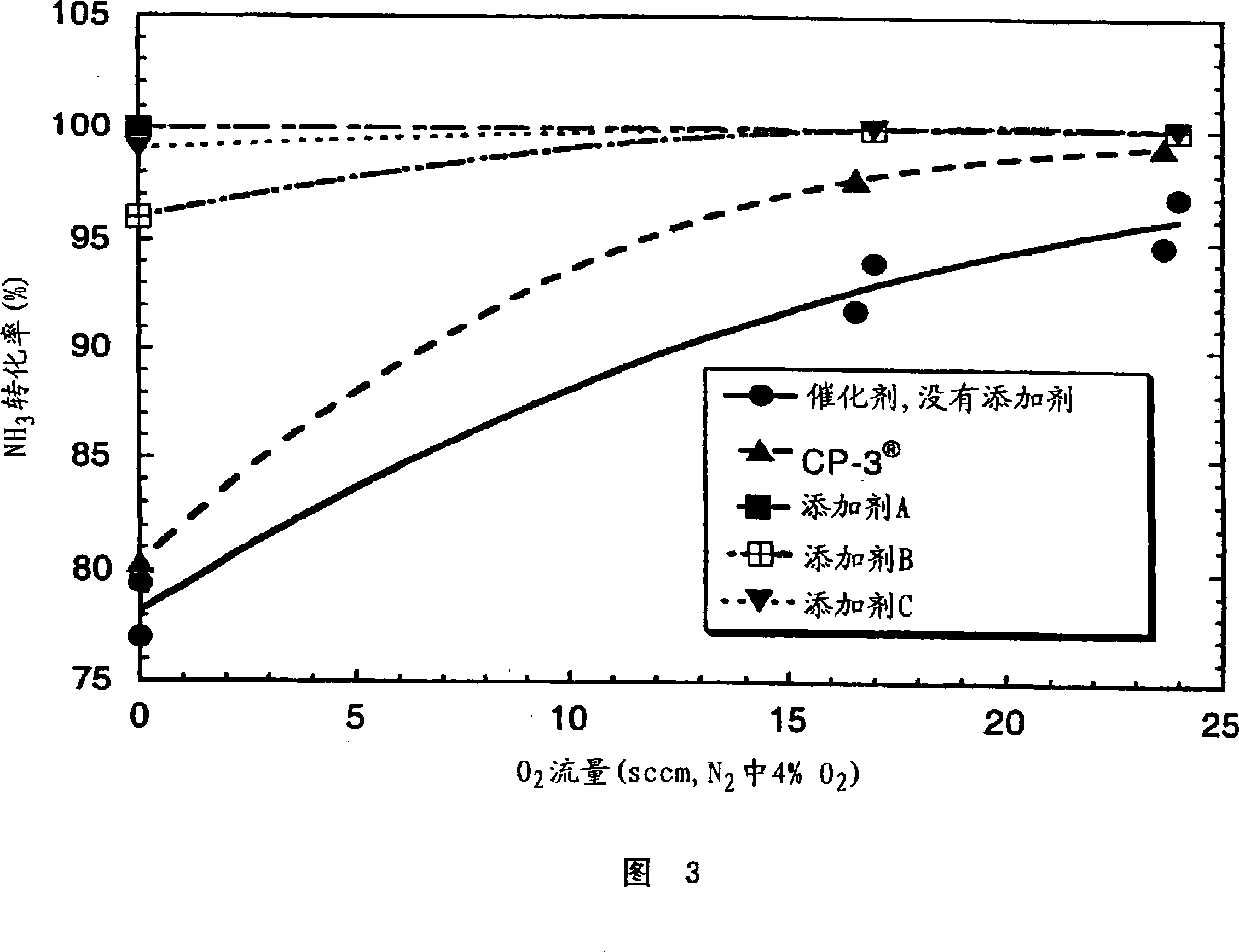

[0073] Determining that the compositions of the present invention reduce gas phase reduced nitrogen species at RTU without converting them to NO X The model response of the capacity is, in the presence of CO and various amounts of O 2 In the presence of NH 3 Reaction on Crack...

Embodiment 1

[0076] A silica-alumina slurry was prepared by adding 30 lbs of SRSII silica-alumina powder to 57 lbs of water heated to 38°C. (SRSII is sold by Grace Davison, a Business Unit of W.R. Grace & Co.-Corm., (Columbia, MD), a silica-alumina powder containing 6% SiO 2 , 94% Al 2 o 3 , with a water content of 33%. ) The slurry was prepared in a steam jacketed stainless steel tank equipped with an electric stirrer. Mix 6 lbs of aqueous hydrochloric acid (35% HCl) and 6.7 lbs of aqueous solution of aluminum ehlorohydrol (22% Al 2 o 3 ) was added to the silica-alumina slurry. The mixture was heated to 55°C, and the mixture was aged at this temperature for 4 hours with continuous stirring. After the aging period, 15.3 pounds of cerium carbonate crystals (obtained from Rhone Poulenc, Inc., 96% CeO 2 , 4% La 2 o 3 , moisture 50%) was added to the tank, and 30 pounds of water was added to the tank to reduce the solids content of the slurry to 20 wt%.

[0077] The mixture was mille...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com