Method of resource protection, decrement treatment of town sewage and sludge

A technology of urban sewage and recycling, applied in chemical instruments and methods, dehydration/drying/concentrated sludge treatment, sludge treatment, etc., can solve the problems of sludge reduction effect and unsatisfactory same-liquid separation performance, and achieve Reduce sludge treatment costs, obvious environmental benefits, and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

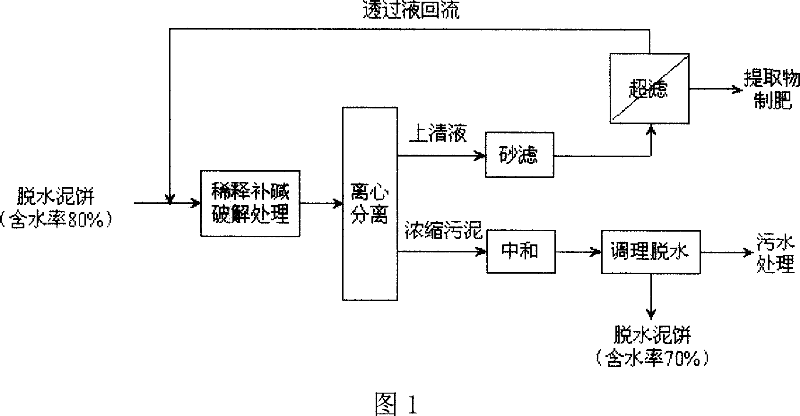

[0018] The invention provides a reduction and recycling method of urban sewage sludge. Fig. 1 is a schematic diagram of the method for realizing sludge reduction and resource utilization by alkali treatment of the present invention, and the following examples are given in conjunction with Fig. 1 to illustrate the present invention,

[0019] The dehydrated cake produced by an urban sewage treatment plant has a moisture content of 81%, an organic matter content of 64%, and a pH of 6.86.

[0020] Dilute the dehydrated cake to a water content of 96%, add sodium hydroxide to make the concentration reach 12g / L, stir for 4 hours, and the treated sludge enters the centrifuge for separation. The separation factor is 3000 rpm to obtain a water content of 90%. The concentrated sludge and supernatant, the chemical oxygen demand (COD) of the supernatant is 10076mg / L, and the content of humic acid is 2996mg / L. The concentrated sludge is neutralized with sulfuric acid to pH = 7, and diluted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com