White light GaN LED epitaxial material without fluorescent powder conversion and method for making the same

A technology for light-emitting diodes and epitaxial materials, which is applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of lack of UV radiation resistance, limited light-emitting quality of white light-emitting diodes, low light-emitting efficiency, etc., and achieves increased device complexity. The effect of improving light utilization efficiency and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Using the method of the present invention and the white light GaN light-emitting diode epitaxy material of the present invention that does not require phosphor powder conversion to prepare a GaN single-tube-core white light light-emitting diode that does not require phosphor powder conversion, the steps are as follows:

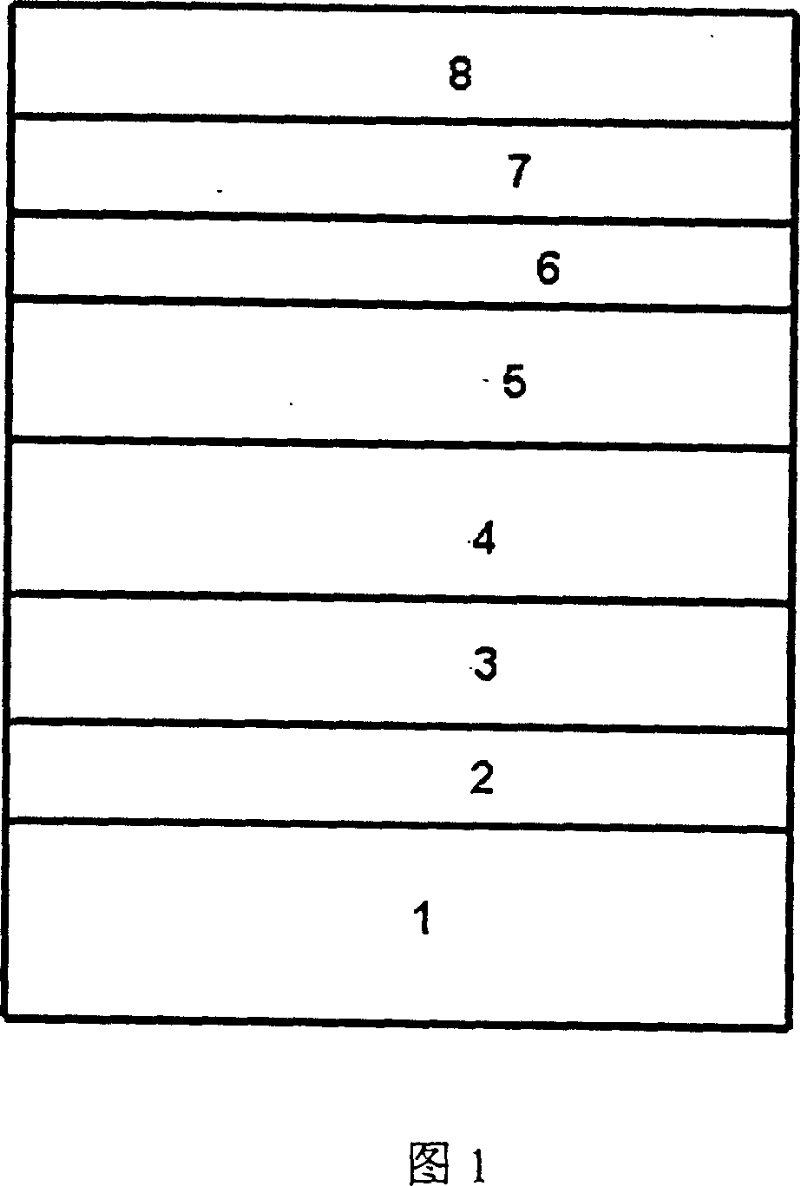

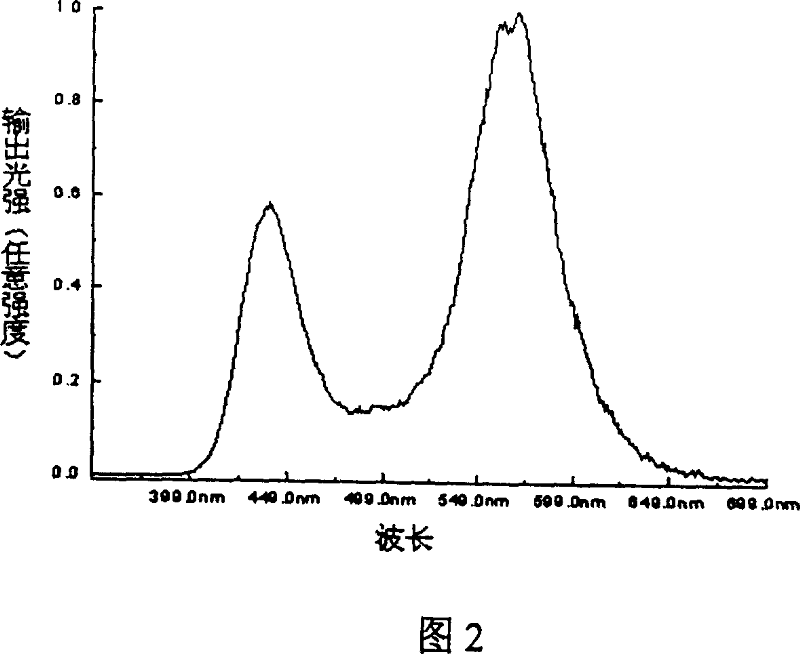

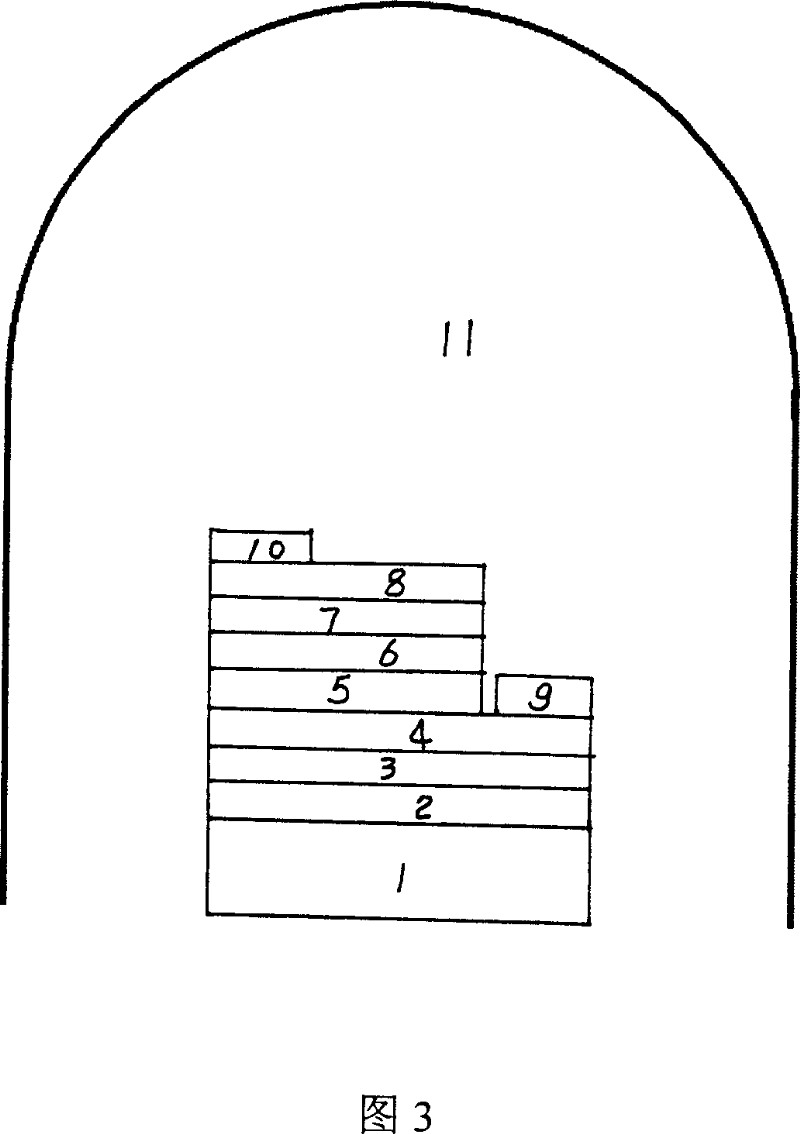

[0036] 1) Using 0.43mm thick sapphire as the substrate 1, the GaN initial growth layer 2, the intrinsic GaN layer 3 (composed of GaN), and the 500nm thick n Type GaN layer 4 (composed of GaN), 1 μm thick InGaN relaxation layer 5 (composed of In 0.1 Ga 0.9 N composition), InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer In 0.05 Ga 0.95 N and quantum well layer In 0.15 Ga 0.85 5 periods of multiple quantum wells composed of N, in which the barrier layer In 0.05 Ga 0.95 The thickness of N is 10nm, the quantum well layer In 0.15 Ga 0.85 The thickness of N is 3nm, the barrier layer In y Ga 1-y The doping concentration...

Embodiment 2

[0042] Using the method of the present invention to prepare white light GaN light-emitting diode epitaxial materials that do not require phosphor powder conversion, the steps are as follows:

[0043] SiC with a thickness of 0.4 mm is used as the substrate 1, and an initial GaN growth layer 2, an intrinsic GaN layer 3 (composed of AlN), and n-type AlN with a thickness of 1 μm are sequentially grown on it by metal-organic chemical vapor deposition (MOCVD) Layer 4 (composed of GaN), 500nm thick InGaN relaxation layer 5 (composed of GaN), InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer GaN and quantum well layer In 0.15 Ga 0.85 4 periods of multiple quantum wells composed of N, in which the thickness of the barrier layer GaN is 12nm, and the quantum well layer In 0.15 Ga 0.85 The thickness of N is 5nm, the barrier layer In y Ga 1-y The doping concentration of N is 1×10 18 / cm 3 0, quantum well layer In x Ga 1-x The doping concentration of th...

Embodiment 3

[0045] Using the method of the present invention to prepare white light GaN light-emitting diode epitaxial materials that do not require phosphor powder conversion, the steps are as follows:

[0046] A 0.3 mm thick silicon substrate is used as the substrate 1, and a 200 nm thick AlN initial growth layer 2, a 1 μm thick intrinsic GaN layer 3 (composed of InGaN), 0.5 μm thick n-type GaN layer 4 (made of AlGaN), 10 nm thick InGaN relaxation layer 5 (made of In 0.2 Ga 0.8 N composition), InGaN multi-quantum structure light-emitting layer 6 (composed of barrier layer GaN and quantum well layer In 0.15 Ga 0.85 4 periods of multiple quantum wells composed of N, in which the thickness of the barrier layer GaN is 12nm, and the quantum well layer In 0.15 Ga 0.85 The thickness of N is 5nm, the barrier layer In y Ga 1-y The doping concentration of N is 1×10 17 / cm 3 , the quantum well layer In x Ga 1-x The doping concentration of the N layer is 2×10 17 / cm 3 ), 0nm thick p-typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com