Wastewater treatment technique for PMIDA preparation process

A wastewater treatment and preparation process technology, applied in the direction of neutralization water/sewage treatment, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem that diglyphosate has not been recycled, and achieve the effect of value improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

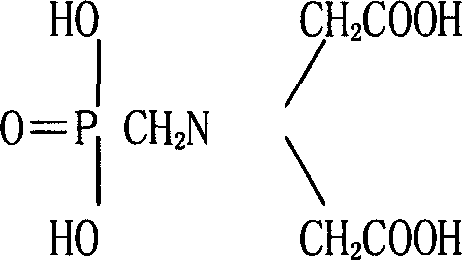

Image

Examples

Embodiment 1

[0021] Add 10,000kg of mother liquor produced during the preparation of diglyphosate into the reactor, adjust the pH to 2.0 with sodium hydroxide, and filter the adjusted pH of the mother liquor of bisglyphosate through a filter press, bag filter or precision filter Pump into the raw material liquid tank, the bisglyphosate mother liquid in the raw material liquid tank uses a pump with a lift of 20m to pump the raw material liquid into a multimedia filter containing activated carbon to remove the viscous liquid in the mother liquid, and then passes through a microporous filter membrane with a pore size of 50 μm The micron particles in the mother liquor are directly removed, and then divided into two streams after being separated by an ultrafiltration membrane. The concentrated side liquid returns to the raw material liquid tank, and the light side liquid enters the secondary membrane system after being pressurized by a high-pressure pump. Diglyphosate mother liquor solution ente...

Embodiment 2

[0025] The liquid 1000kg in No. 1 liquid storage tank among the embodiment 1 is joined in the autoclave, start stirring, then add 1500kg deionized water, 300kg mass fraction successively and be 90% bisglyphosate, 10kg gac catalyst, be warming up to 60 ℃, feed oxygen, control reaction temperature 62±2℃, reaction pressure 0.6Mpa, react for 2 hours, remove catalyst by filtration, cool and crystallize filtrate, obtain 190kg of glyphosate with a mass fraction of 96% after drying crystals obtained by filtration, filtrate 2600kg is concentrated to make 200kg of 10% glyphosate aqueous solution. The yield of glyphosate is 99.75% based on the solid input of diglyphosate.

Embodiment 3

[0027] Add 10,000kg of mother liquor produced during the preparation of bisglyphosate into the reaction kettle, adjust the pH to 7.0 with sodium hydroxide, pump it into the raw material liquid tank after pressure filtration, and pump the raw material liquid into the multi The medium filter is filtered by a microporous membrane with a pore size of 20 μm and then enters the ultrafiltration. The concentrated side liquid returns to the raw material liquid tank, and the light side liquid enters the secondary membrane system after being pressurized by a high-pressure pump. Diglyphosate mother liquor solution entering the secondary membrane system is divided into two strands after membrane separation, and the solution rich in diglyphosate on the thick side is returned to the front-end inlet. When the concentration of diglyphosate in the solution reaches 20%, the concentrate Into the No. 1 liquid storage tank, a total of 1000kg, the light side solution is pressurized by a high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com