Plasma treating apparatus and plasma treating method

A plasma and processing device technology, applied in the field of ion plasma processing devices, can solve problems such as insufficient countermeasures, and achieve the effect of improving etching speed and etching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

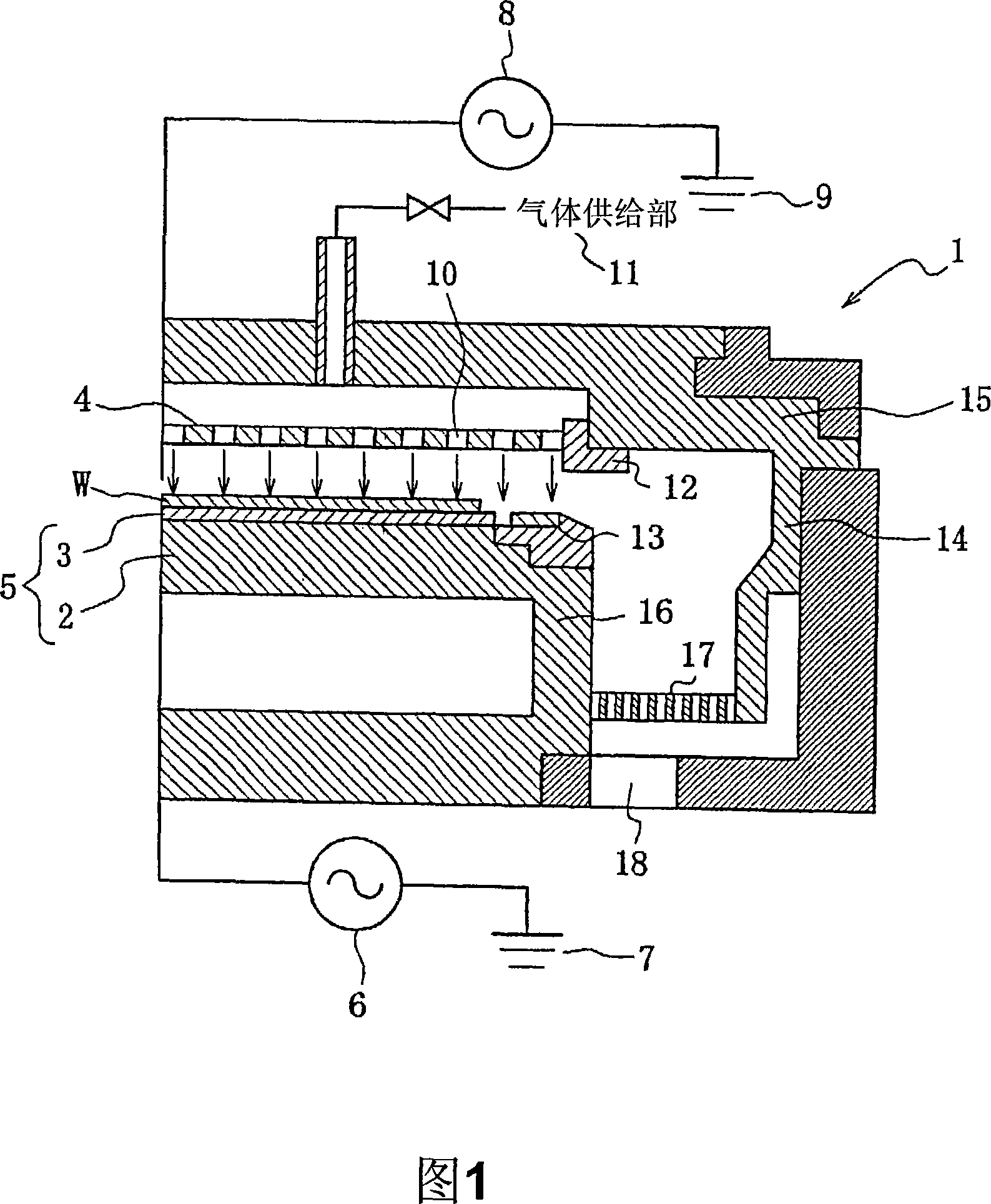

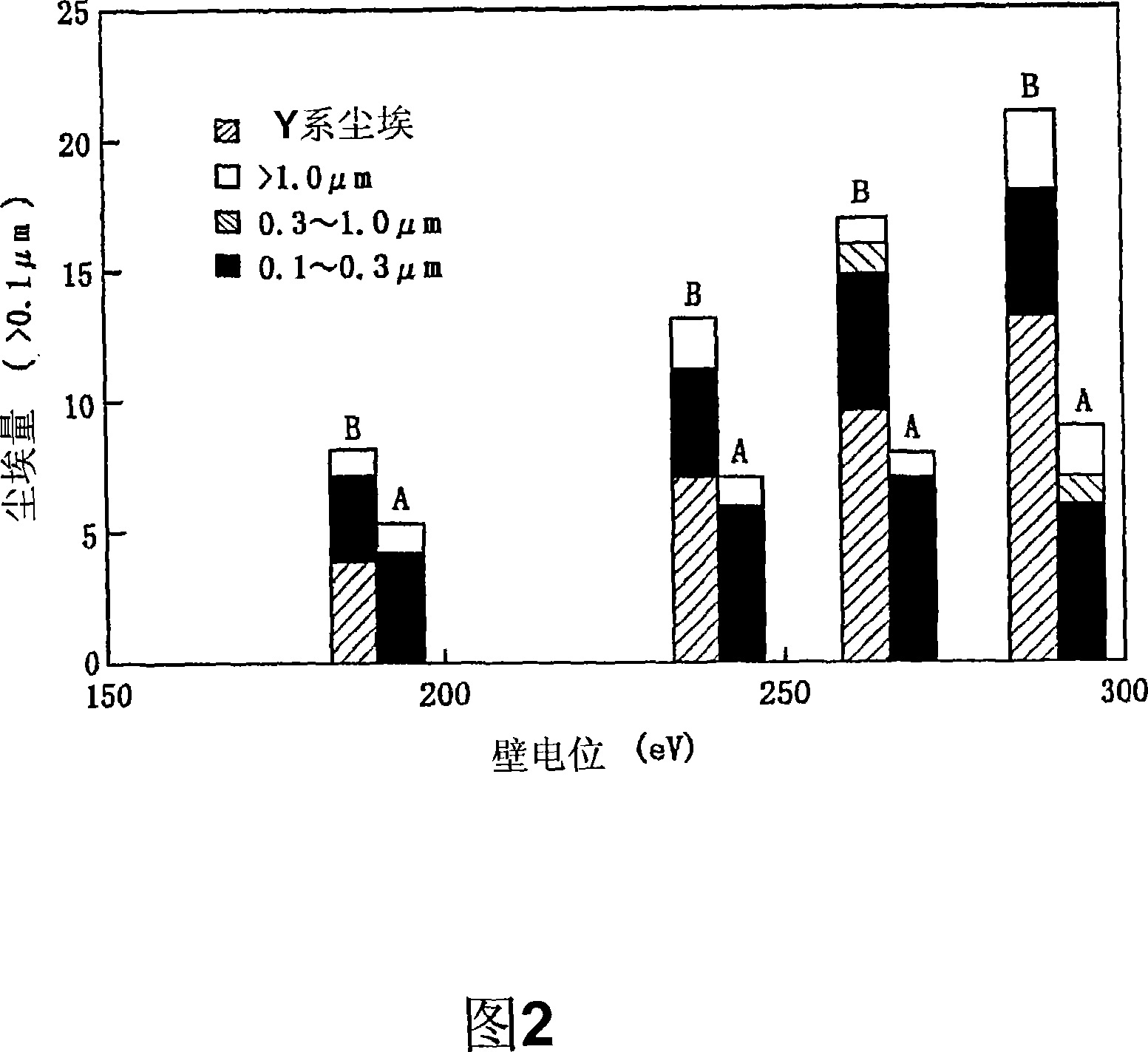

[0105] On the surface of the chamber inner wall member (aluminum baffle) of the plasma processing apparatus shown in FIG. 1, Y 2 o 3 (purity is more than 95mass%), obtains the part (comparative example B) that is formed with film; 2 o 3 After forming the film, the surface was irradiated with electron beams to undergo secondary transformation to form a member having a secondary crystal layer (invention example A). In each chamber, F-containing gas and CH-containing gas are alternately and repeatedly introduced, and plasma treatment is performed to make the above Y 2 o 3 After the sprayed coating is weakened, by controlling the amount of high-frequency power applied to the mounting table of the semiconductor wafer as the object to be plasma processed, the potential difference between the chamber wall potential and the plasma is changed from 200V to 300V, and each potential difference is measured. The amount of dust (particles) generated under the semiconductor wafer. The re...

Embodiment 2

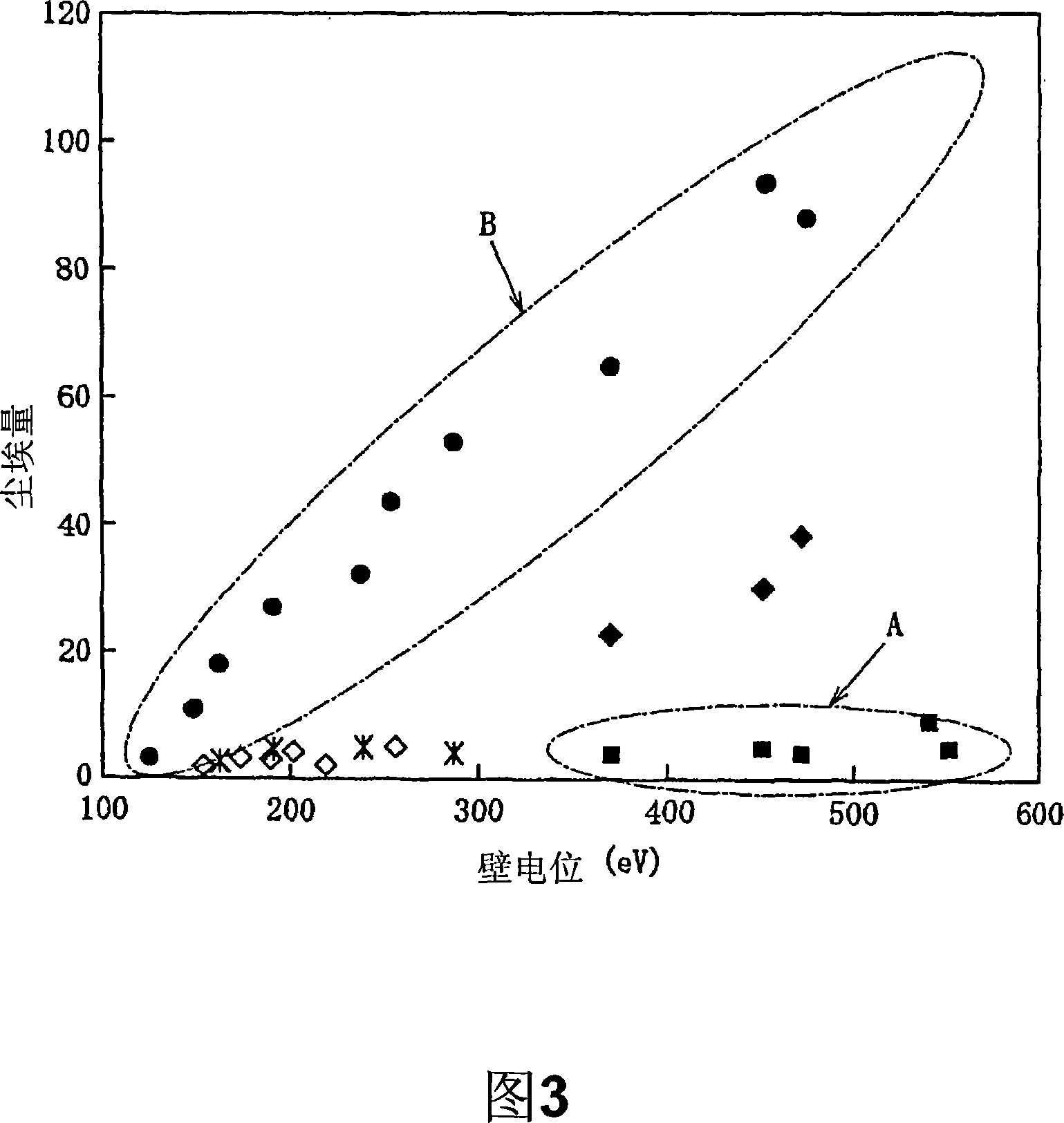

[0108] In order to investigate the limit value of the potential difference between the inner wall parts of the plasma processing container (aluminum lower insulator, baffle plate, deposit shield) and the plasma (the range that can suppress the generation of dust caused by the film (yttrium)), and Embodiment 1 prepares in the same way: on the surface of processing container inner wall parts, spray Y 2 o 3 And form the part (comparative example B) that has film; And in spraying Y 2 o 3 After the film was formed, the surface was irradiated with electron beams to undergo secondary transformation to form a component with a secondary crystal layer (invention example A). In each processing container, F-containing gas and CH-containing gas are introduced alternately and repeatedly for plasma treatment, so that Y 2 o 3 After the film was weakened, the amount of high-frequency power applied to the lower electrode was controlled to change the potential difference between the componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com