Method for separating and purifying 10-deacetyl Baccatins III

A technology for removing acetylation and ethyl acetate, which is applied in the field of separation and purification of 10-deacetylbaccatin III combined with forward and reverse phase liquid chromatography technology, can solve the problems of incomplete separation of impurities, small processing capacity, and high cost, and achieve The solvent is easy to recycle and cheap, prolongs the service life, and has the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

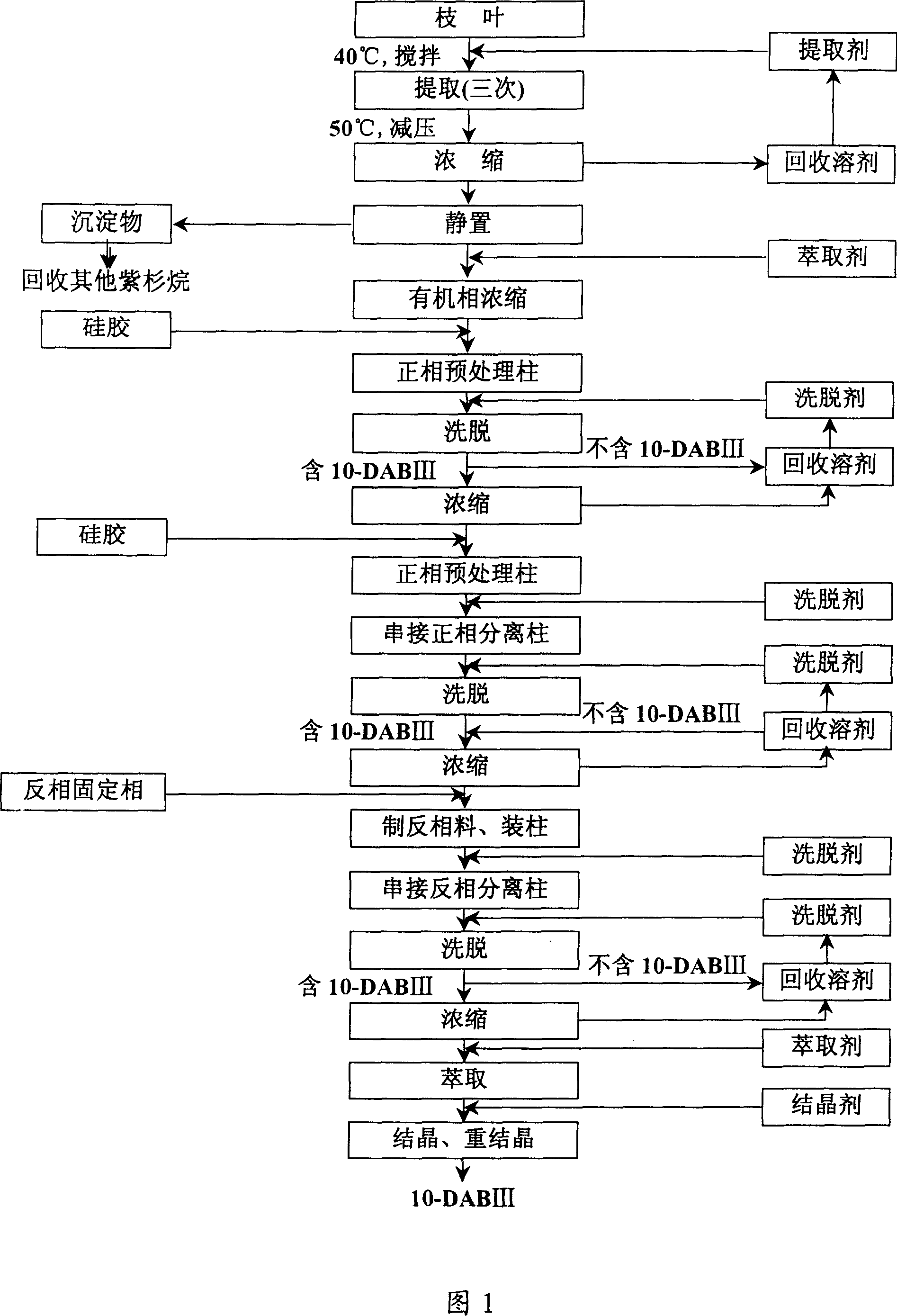

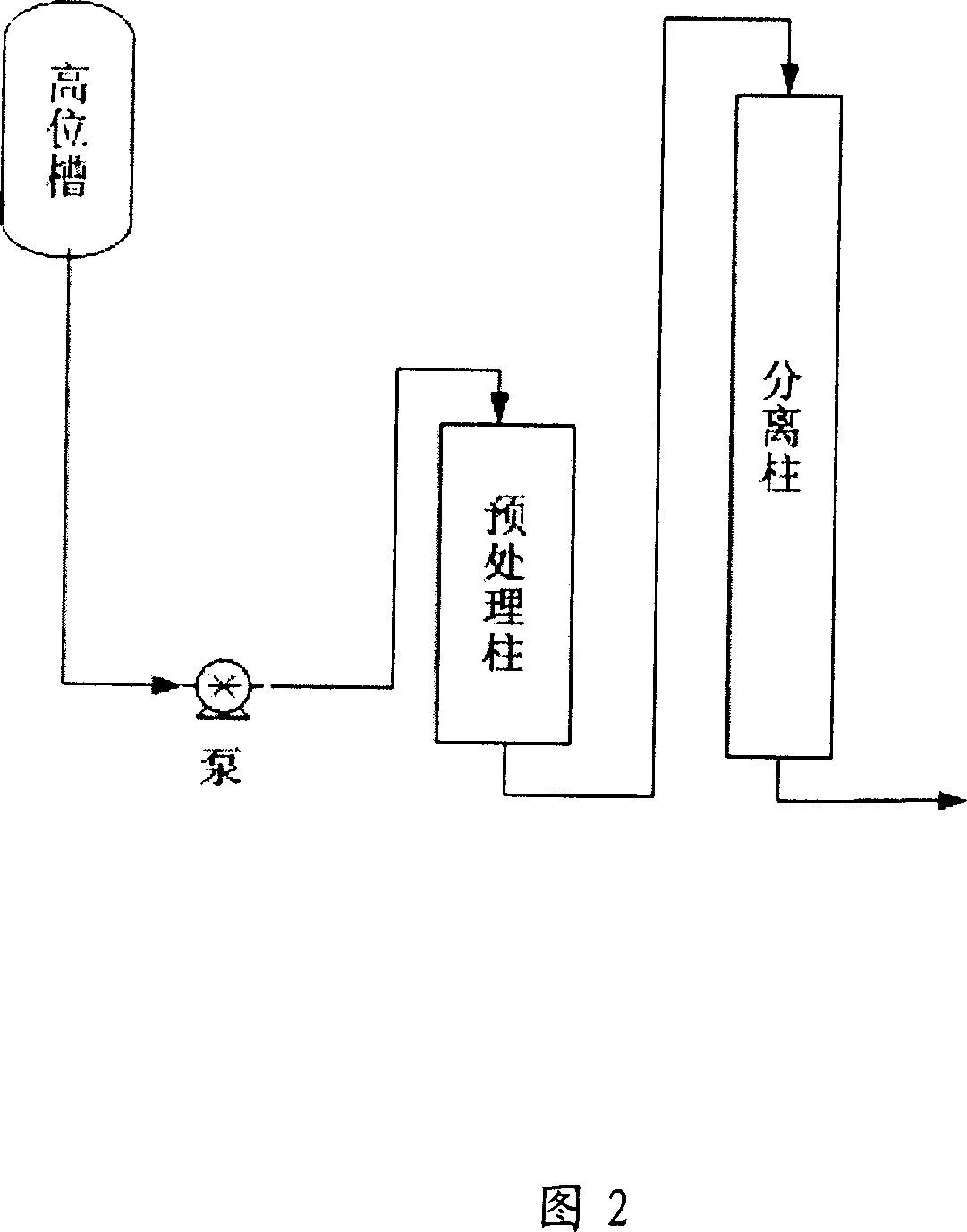

[0037] Refer to Figure 1 for the process flow diagram of this embodiment, and refer to Figure 2 for the serial connection of the pretreatment column and the separation column.

[0038] (1) Take 1 kg of pulverized European yew (T.baccata) branches and leaves, add 7L of 50% methanol aqueous solution, keep a constant temperature water bath at 40°C, stir and extract for 8 hours, filter to obtain a primary extract and a primary filter residue;

[0039] (2) Return the primary filter residue to the extraction container, then add 5L of 50% methanol aqueous solution, keep a constant temperature water bath at 40°C, stir and extract for 8 hours, and filter to obtain the secondary extract and secondary filter residue;

[0040] (3) return the secondary filter residue to the extraction container, then add 5L of 50% methanol aqueous solution, keep a constant temperature water bath at 40° C., stir and extract for 8 hours, and filter to obtain three extractions and three filter residues;

[00...

Embodiment 2

[0055] Get 1 kilogram of Canadian yew (T.canadensis), and the specific operation steps are the same as in Example 1, and the difference is: the extract in step (1) is replaced with 70% acetone, and leached three times; the fixation in step (10) The phase is replaced by coated polystyrene-divinylbenzene, the eluent in step (11) is replaced by 5-50% ethanol aqueous solution, and the separation is repeated twice; the extractant in step (13) is replaced by butyl acetate , the crystallization agent in the step (14) was replaced with petroleum ether; after drying, 0.23 g of 10-DABIII with a purity of 99.61% was obtained, and the yield was 78%.

Embodiment 3

[0057] Get 1 kilogram of Yunnan yew (T.yunnanensis), and the specific operation steps are the same as in Example 1, and the difference is that the extract in step (1) is replaced with 65% ethanol, and leached three times; the fixation in step (10) The phase is replaced by cross-linked polystyrene-divinylbenzene, the eluent in step (11) is replaced by 5-50% acetonitrile aqueous solution, and the separation is repeated twice; the extractant in step (13) is replaced by methyl acetate , the crystallization agent in step (14) was replaced by cyclohexane; after drying, 0.18 g of 10-DABIII with a purity of 99.55% was obtained, and the yield was 76%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com