Negative photosensitive resin composition

A photosensitive resin and composition technology, applied in optics, opto-mechanical equipment, instruments, etc., can solve the problems of storage stability such as molecular weight increase, sensitivity and pattern shape change, difficulty in obtaining adhesive strength, etc., to achieve performance Excellent, excellent UV transmittance, improved sensitivity and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (manufacturing of acrylic copolymers)

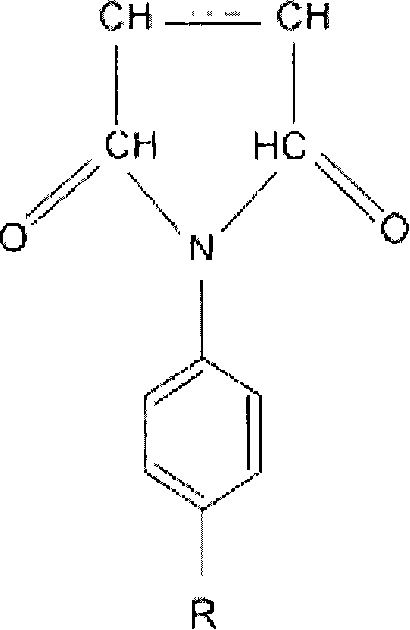

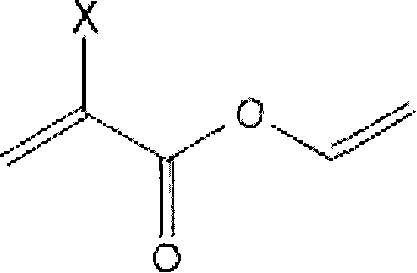

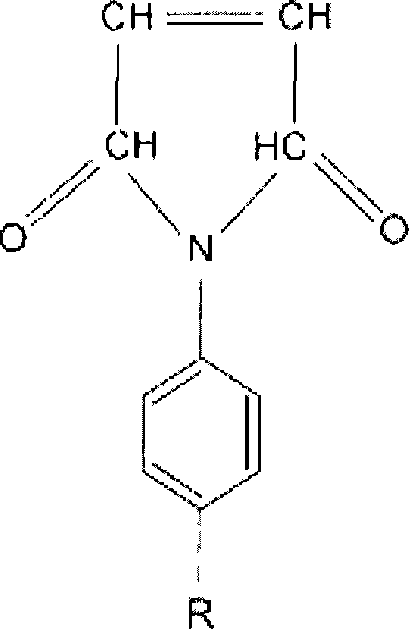

[0087] Add 10 parts by weight of 2,2'-azobis(2,4-dimethylvaleronitrile), 400 parts by weight of propylene glycol monomethyl ether acetate, 30 parts by weight in the flask equipped with condenser tube and stirrer Parts by weight of methacrylic acid, 30 parts by weight of allyl methacrylate, 10 parts by weight of 4-hydroxyphenylmaleimide of the above chemical formula 1 and 30 parts by weight of styrene, slowly carry out after nitrogen exchange Stir. The temperature of the reaction solution was raised to 55° C. and maintained at this temperature for 24 hours to produce a polymer solution containing an acrylic copolymer.

[0088] Add the above-produced acrylic copolymer dropwise to 5000 parts by weight of hexane, and the copolymer is precipitated. After the copolymer is separated by filtration, 200 parts by weight of propionate are added to the copolymer and heated to 30°C to produce a solid A polymer solution having a polymer conce...

Embodiment 2

[0092] In the manufacture of the acrylic copolymer of the above-mentioned embodiment 1, 20 parts by weight of 4-hydroxyphenylmaleimide of the above chemical formula 1 was used, 30 parts by weight of methacrylic acid, 30 parts by weight of allyl methacrylate , 20 parts by weight of styrene, the manufacture of solids concentration is 45% by weight, the weight average molecular weight of the polymer is an acrylic copolymer of 17800, except that, operate with the method identical with above-mentioned embodiment 1, manufacture negative photosensitive Resin composition coating solution.

Embodiment 3

[0094] In the manufacture of the acrylic copolymer of the above-mentioned embodiment 1, use 30 parts by weight of 4-hydroxyphenylmaleimide of the above chemical formula 1, use 30 parts by weight of methacrylic acid, 30 parts by weight of allyl methacrylate , 10 parts by weight of styrene, the manufacture of solid concentration is 45% by weight, the weight-average molecular weight of the polymer is an acrylic copolymer of 18100, except that, operate with the method identical with above-mentioned embodiment 1, manufacture negative photosensitive Resin composition coating solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com