Multipoint water feeding sewage treatment process by zeolite and organism united adsorption and regeneration

A multi-point water intake and sewage treatment technology, which is applied in the fields of adsorption water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , difficult to popularize and apply, etc., to achieve the effect of maintaining stable operation with long mud age, good sedimentation, and saving capital investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

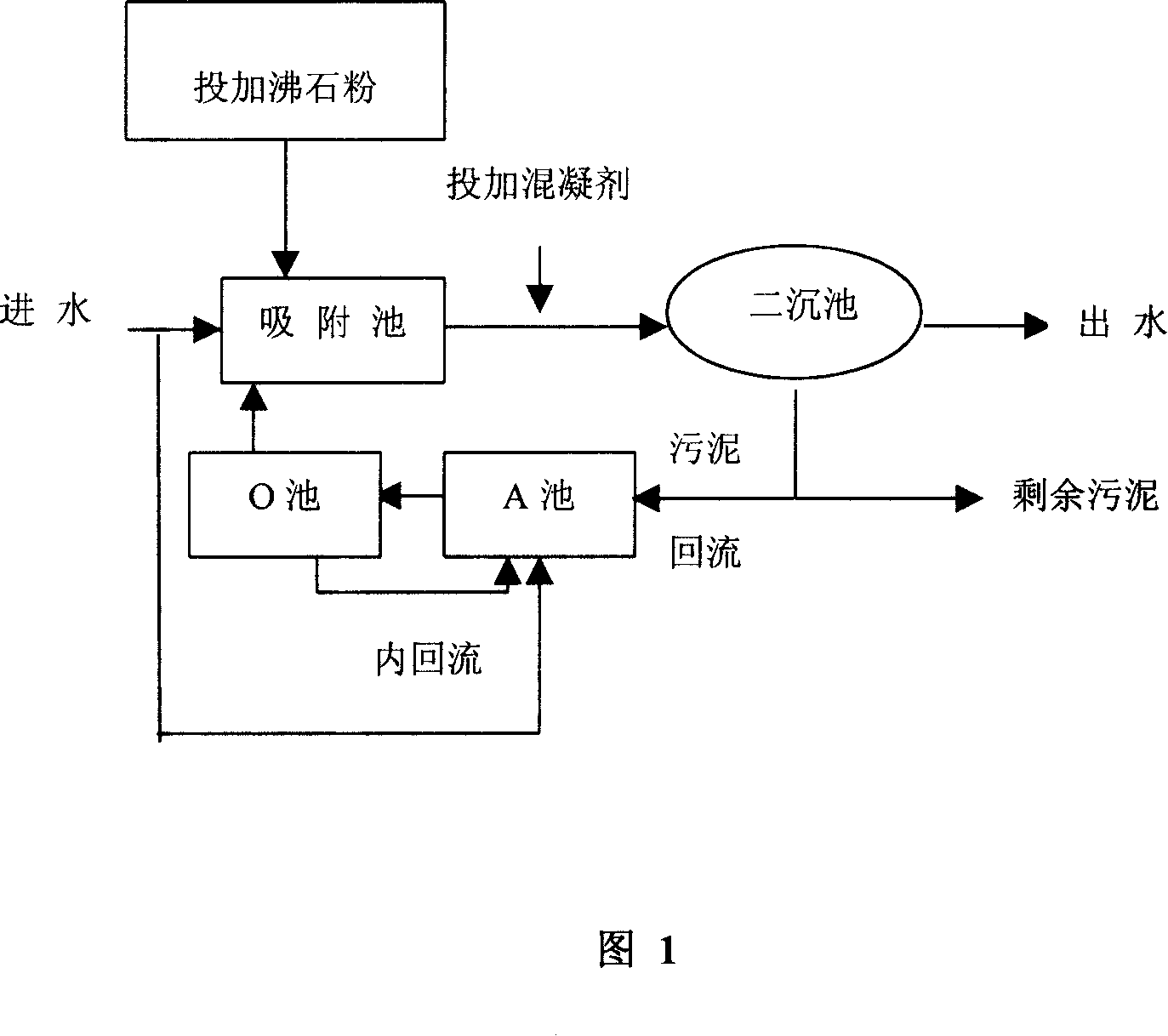

[0018] The sewage treatment process of the present invention is composed of zeolite biological joint adsorption regeneration treatment process, A / O denitrification process and chemical phosphorus removal method. Be as follows the embodiment of sewage treatment process of the present invention:

[0019] Intake of water: Q 0 = 3m 3 / h, among them, the water intake of the adsorption tank is 5 / 6Q 0 , 1 / 6Q of water intake in anoxic pool 0 COD=300mg / L,NH 4 + -N=40mg / L, SRT=40d

[0020] Adsorption pool: HRT=45min, SS=15000mg / L, in which the concentration of zeolite is 10000mg / L

[0021] N V =8kgBOD 5 / m 3 .d, N S =0.53kgBOD 5 / kgMLSS.d

[0022] Air-to-water ratio = 10:1, add a stirrer to fully stir

[0023] Sedimentation tank: Sedimentation time HRT = 1.5h (not included in biological treatment time)

[0024] Regeneration section: reflux ratio R=0.5 internal reflux r=1

[0025] Pool A: HRT=1.1h

[0026] O pool: HRT=2h

[0027] SS=35000mg / L, in which th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com