Red luminescence phosphor

A technology of red luminescence and fluorescent powder, which is applied in the direction of luminescent materials, sustainable buildings, climate sustainability, etc., can solve the problem of luminous efficiency, thermal stability and chemical stability that are not yet practical, low luminous efficiency, excitation Poor performance and other problems, to achieve the effect of wide excitation wavelength range, good luminescence performance, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

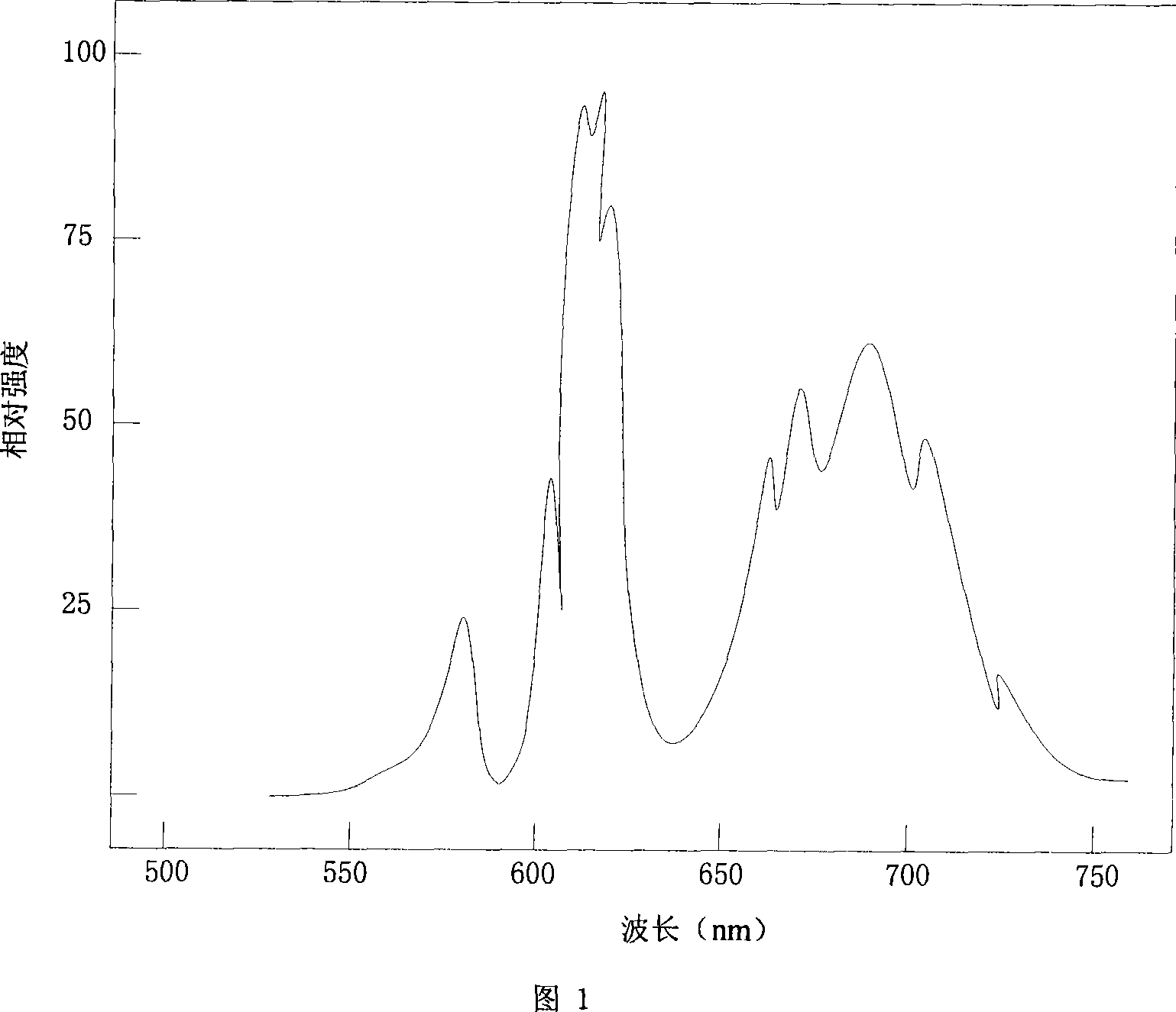

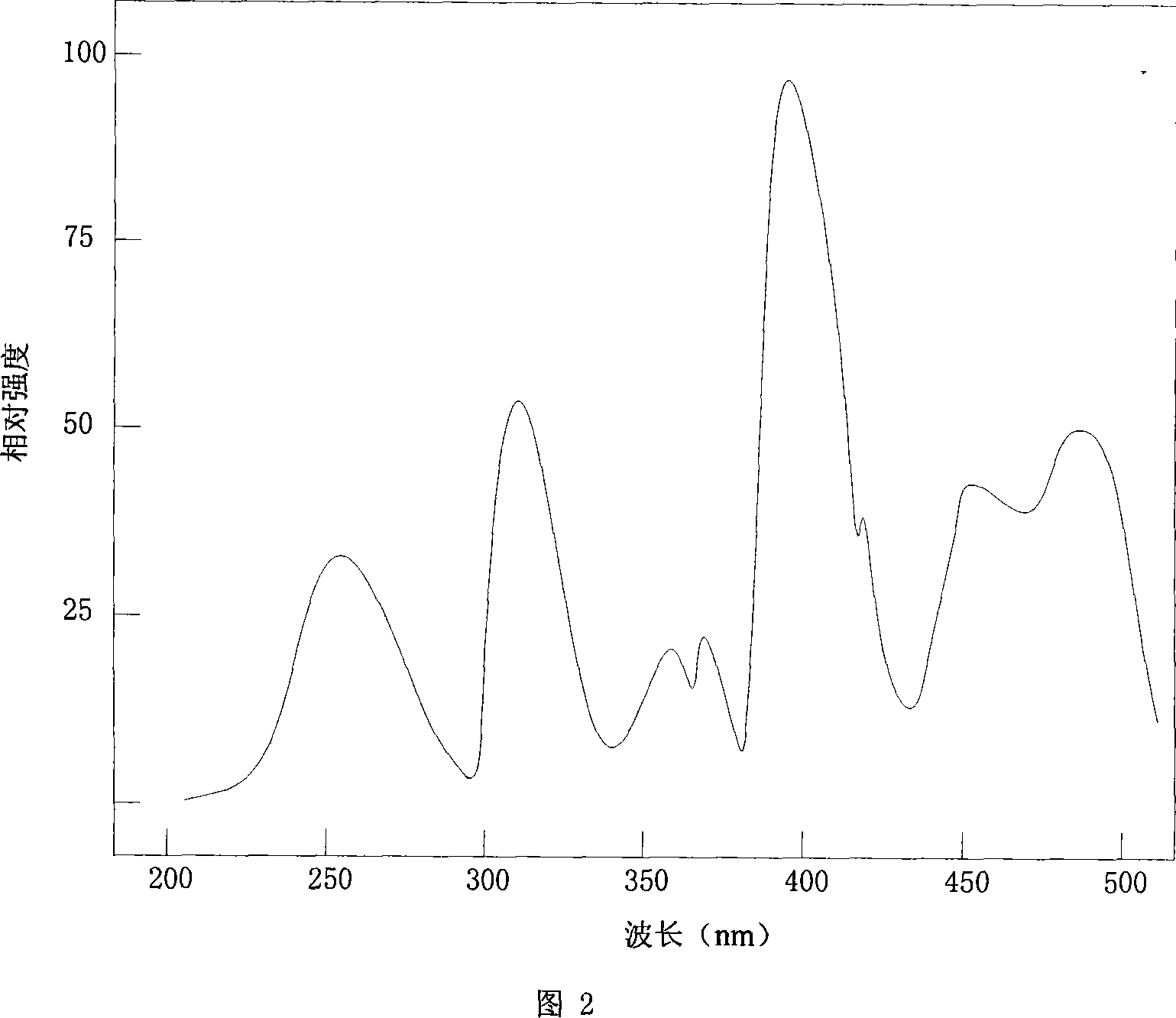

[0018] Embodiment 1: take by weighing zirconium dioxide (ZrO 2 ) 2.46g, alumina (Al 2 o 3 ) 1.8g, lithium carbonate (Li 2 CO 3 ) 0.74g, boric acid (H 3 BO 3 ) 0.25g, diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) 2.68g, manganese dioxide (MnO 2 )0.02g, europium trioxide (Eu 2 o 3 ) 0.04g, after fully grinding and mixing evenly, put it into an alumina crucible and roast in the air, keep it warm at 1100°C for 3 hours, and grind the obtained sintered product finely to obtain the final product. Its emission spectrum is shown in Figure 1, the main emission peak is around 615nm, and there is also a strong emission in the range of 665-710nm, showing pure red light emission overall; its excitation spectrum is shown in Figure 2, the main excitation peak is around 395nm, which can be detected by Ultraviolet light, purple light or blue light in the range of 240-500nm can be effectively excited, especially in the 390-405nm purple light band and 455-500nm blue light band, whic...

Embodiment 2

[0019] Embodiment 2: take by weighing zirconium dioxide (ZrO 2 ) 2.46g, alumina (Al 2 o 3 ) 1.8g, lithium carbonate (Li 2 CO 3 ) 0.74g, boric acid (H 3 BO 3 ) 0.25g, diammonium hydrogen phosphate ((NH 4 ) 2 HPO 4 ) 2.68g, manganese dioxide (MnO 2 ) 0.02g, samarium trioxide (Sm 2 o 3 ) 0.04g, after fully grinding and mixing evenly, put it into an alumina crucible and roast in the air, keep it warm at 1100°C for 3 hours, and grind the obtained sintered product finely to obtain the final product.

Embodiment 3

[0020] Embodiment 3: take by weighing zirconium dioxide (ZrO 2 ) 2.46g, alumina (Al 2 o 3 )0.9g, lithium carbonate (Li 2 CO 3 ) 0.74g, boric acid (H 3 BO 3 ) 0.25g, manganese dioxide (MnO 2 )0.02g, europium trioxide (Eu 2 o 3 ) 0.04g, after fully grinding and mixing evenly, put it into an alumina crucible and roast in the air, keep it warm at 1150°C for 3 hours, and grind the obtained sintered product finely to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com