Process for producing modified aluminium oxide

A production method and technology of alumina, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of low particle strength, unsatisfactory effect, small specific surface area, etc., and achieve large specific surface area, fast filtration speed and large specific surface area. surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

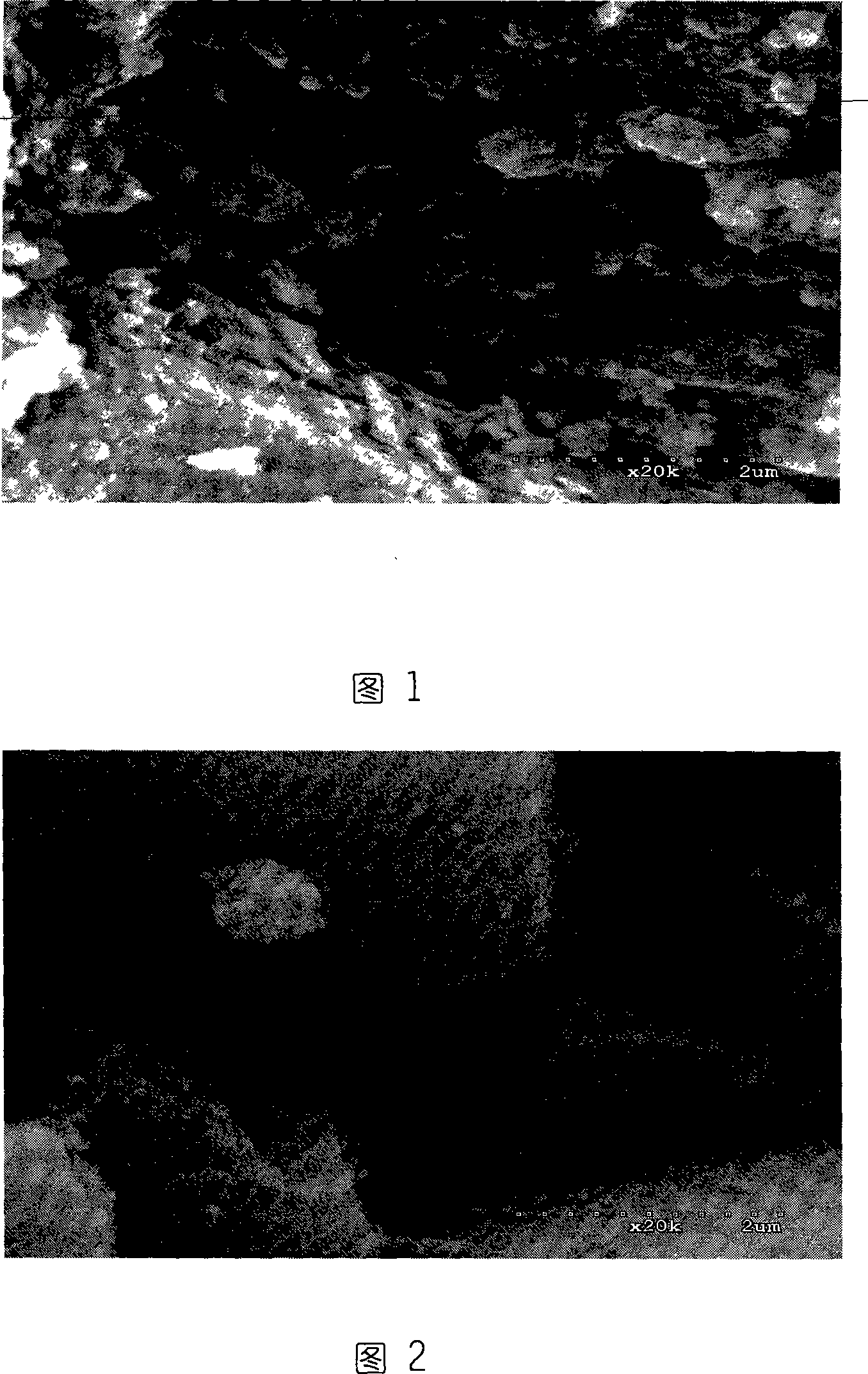

Image

Examples

Embodiment Construction

[0016] Select aluminum hydroxide with crystalline form α or β (obtained by the sorting method), wash with water to remove impurities, and then quickly dry it with an airflow dryer until the moisture content is 5-7%, and then use 5% acetic acid to dry it. Soak in a mixed solution of 0.6% palladium chloride for 1 hour, wherein the weight ratio of the amount of palladium chloride added to aluminum hydroxide is 3:100, then wash with water to remove unreacted acetic acid and palladium chloride, and air flow at 180°C After drying, modified aluminum hydroxide is obtained. The modified aluminum hydroxide is activated in a rotary furnace at 650°C for 1 hour, and then cooled naturally in the air to obtain the modified aluminum oxide for drug decolorization. Check the crystal form and specific surface area of the product, and sieve after passing the test.

[0017] The water after pickling also contains a large amount of acetic acid and palladium chloride, which can be recycled, has no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com