Composite heat-resisting enhance titanium alloy

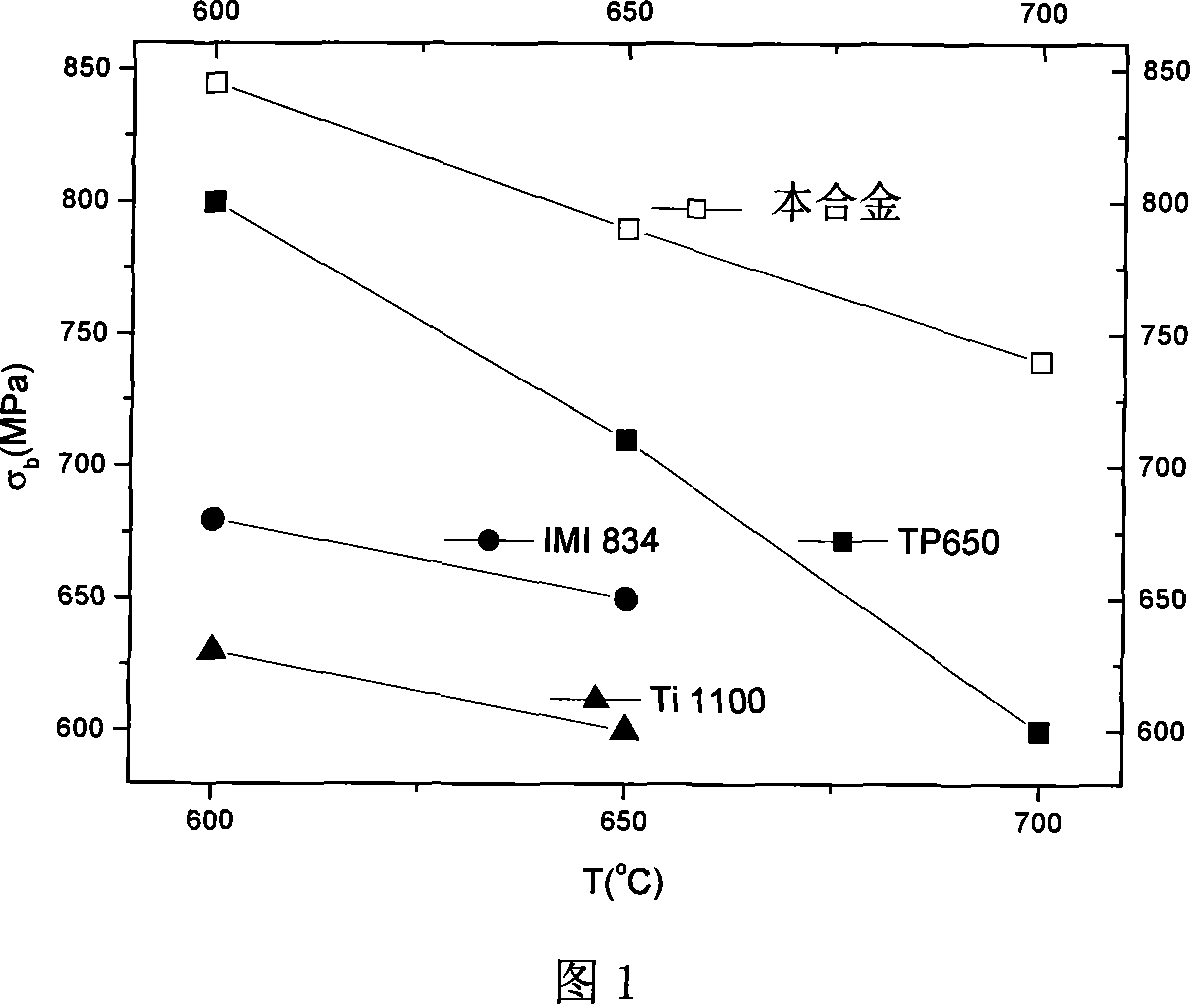

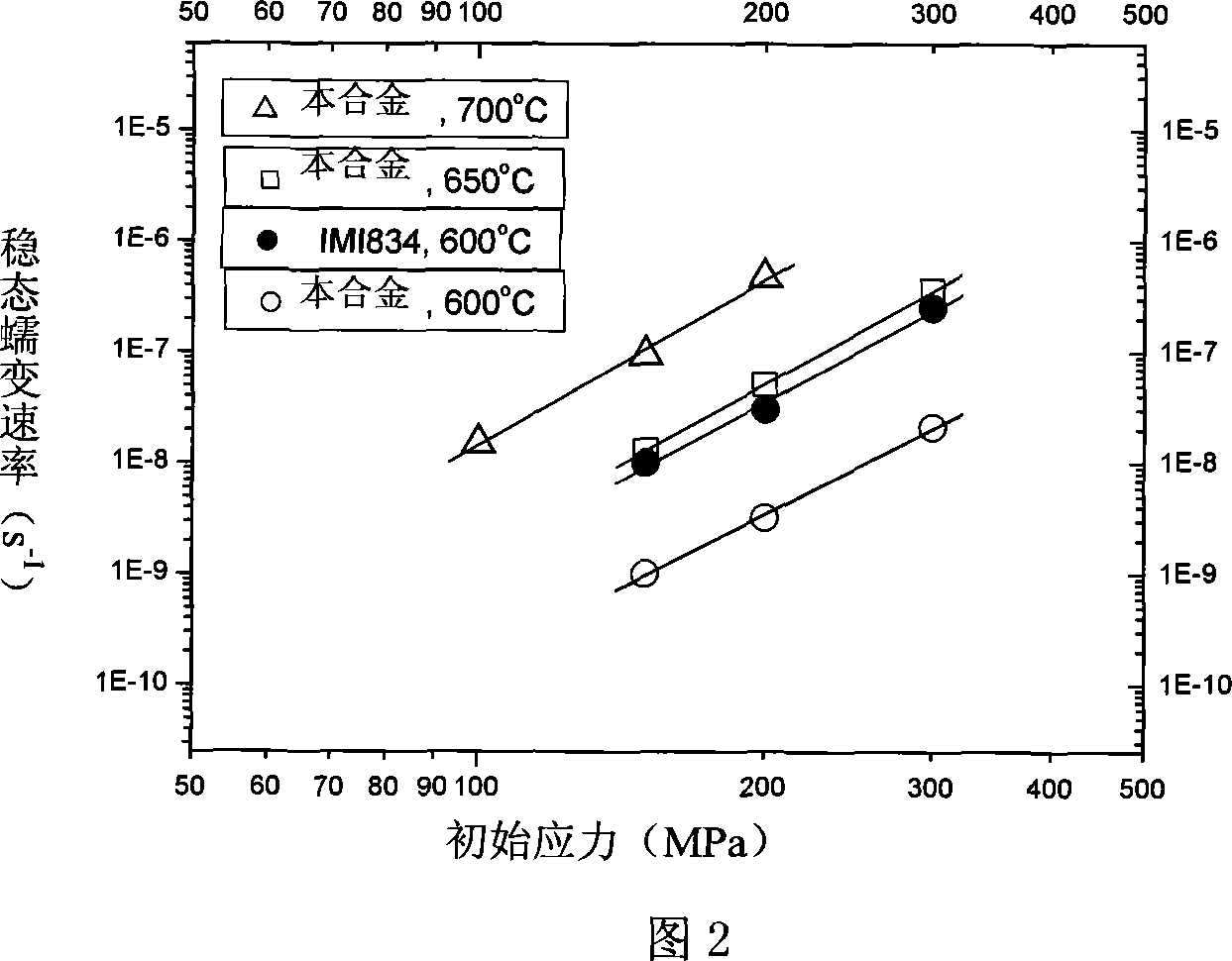

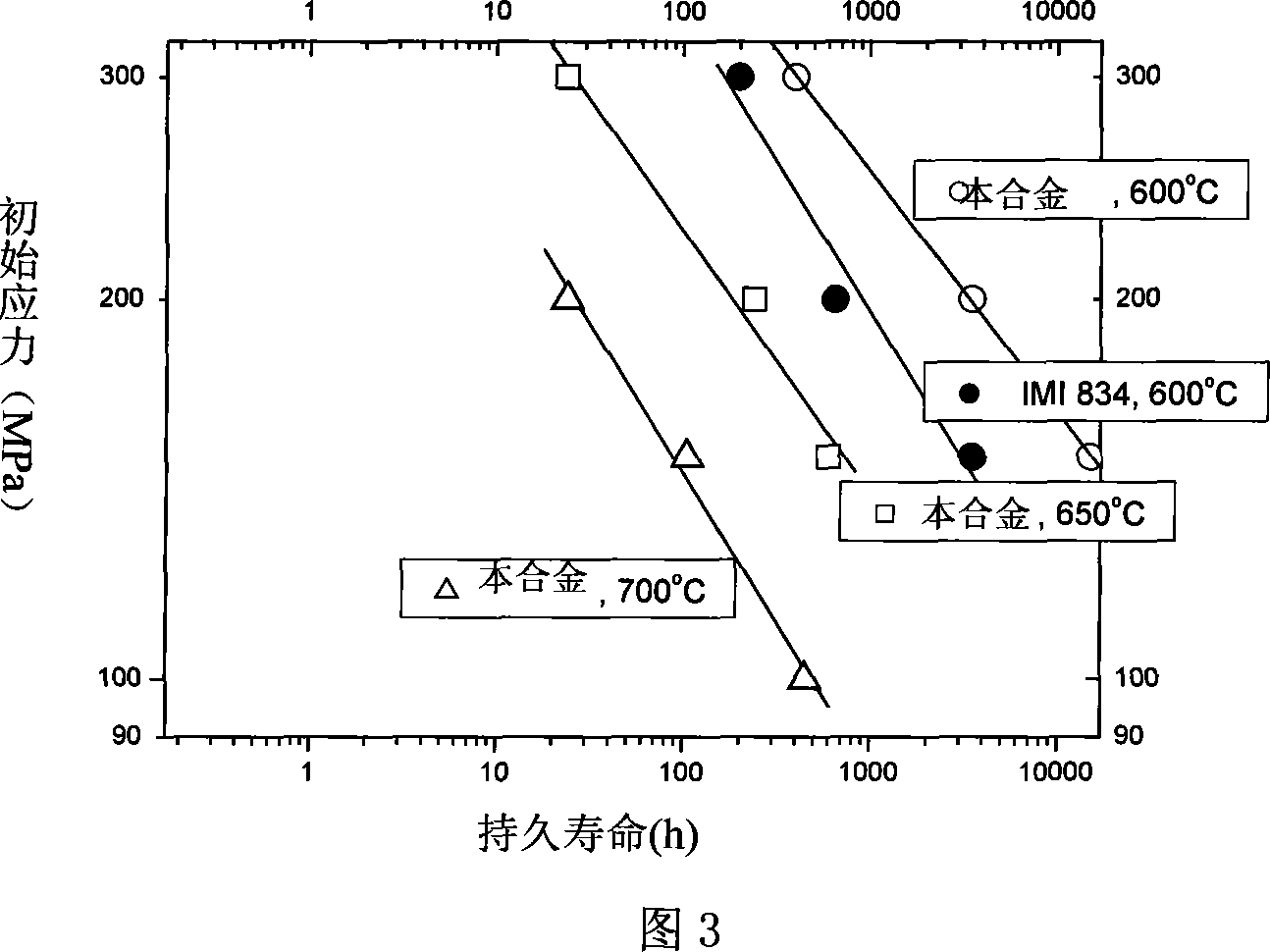

A titanium alloy, heat-resistant technology, applied in the field of titanium alloys, can solve the problems of high specific strength, low room temperature plasticity and fracture toughness, and can not meet the requirements, and achieve the effect of good high temperature stretching, good room temperature plasticity, and low deformation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Weigh first-grade sponge titanium (79.8%), LaB by mass percentage x (70% by mass of La) compound (0.7%), AlNb (53% by mass of Nb) master alloy powder (1.6%), aluminum powder (4.2%), AlMo (50% by mass of Al and Mo) Master alloy powder (2.0%), TiSn (65% by mass of Sn) master alloy powder (6.9%), sponge zirconium (4.5%), crystalline silicon (0.3%), the mass percentage of preparation is Al6%-Sn4.5% -Zr4.5%-Mo1%-Nb0.9%-Si0.3%-La0.5%-B0.2% composite strengthened heat-resistant titanium alloy. The uniformly mixed raw materials are pressed into electrode rods; then the electrodes are put into a vacuum consumable electric arc furnace for one melting to obtain a primary ingot; after two primary ingots are welded by an argon arc welding machine or in a furnace, they are placed in a self-consumable electric arc furnace. The electric arc furnace is used for secondary smelting to obtain secondary ingots; the third smelting process is the same as that of the secondary smelting. The ...

Embodiment 2

[0021] Weigh first-grade sponge titanium (85.05%), LaB by mass percentage 4 (76% by mass of La) compound (0.65%), AlNb (40% by mass of Nb) master alloy powder (1.25%), aluminum powder (2.35%), AlMo (40% by mass of Mo) master alloy powder (1.5%), TiSn (50% by mass of Sn) master alloy powder (6%), sponge zirconium (3%), crystalline silicon (0.2%), the preparation mass percentage is Al4%-Sn3%-Zr3%-Mo0 .6%-Nb0.5%-Si0.2%-La0.4%-B0.15% composite strengthened heat-resistant titanium alloy. According to the same three-time smelting process and thermal processing process as in Example 1, a heat-treatable rod was obtained. Using the recommended heat treatment process: 1100 ° C, 1 hour, air-cooled solution treatment + 650 ° C, 2 hours, air-cooled aging treatment, the overall performance of the heat-resistant titanium alloy obtained is similar to that of Example 1, and the plasticity and thermal stability at room temperature The resistance is slightly better, but the strength and perman...

Embodiment 3

[0023] Weigh first-grade sponge titanium (77.35%), LaB by mass percentage 6 (67% by mass of La) compound (1.3%), AlNb (65% by mass of Nb) master alloy powder (1.5%), aluminum powder (5.7%), AlMo (65% by mass of Mo) master alloy powder (2.3%), TiSn (80% by mass percent of Sn) master alloy powder (6.25%), sponge zirconium (5%), crystalline silicon (0.6%), the mass percent of preparation is Al7%-Sn5%-Zr5%-Mo1 .5%-Nb1%-Si0.6%-La0.9%-B0.4% composite strengthened heat-resistant titanium alloy. According to the same three-time smelting process and thermal processing process as in Example 1, a heat-treatable rod was obtained. Using the recommended heat treatment process: 1100 ° C, 1 hour, air-cooled solution treatment + 650 ° C, 2 hours, air-cooled aging treatment, the overall performance of the heat-resistant titanium alloy obtained is similar to that of Example 1, and the strength and durable creep The performance is slightly better, but the room temperature plasticity and thermal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com