Preparation method of poly dimethyl allyl ammonium chloride with high relative molecular mass

A technology of dimethyl diallyl ammonium chloride and relative molecular weight, which is applied in the field of preparation of cationic water-soluble polymers, can solve the problem of not being able to point out the type of impurities and their content, difficult to obtain reliable results, and low degree of industrialization and other problems, to achieve the effect of high relative molecular weight of the product, good economy and applicability, and lower activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

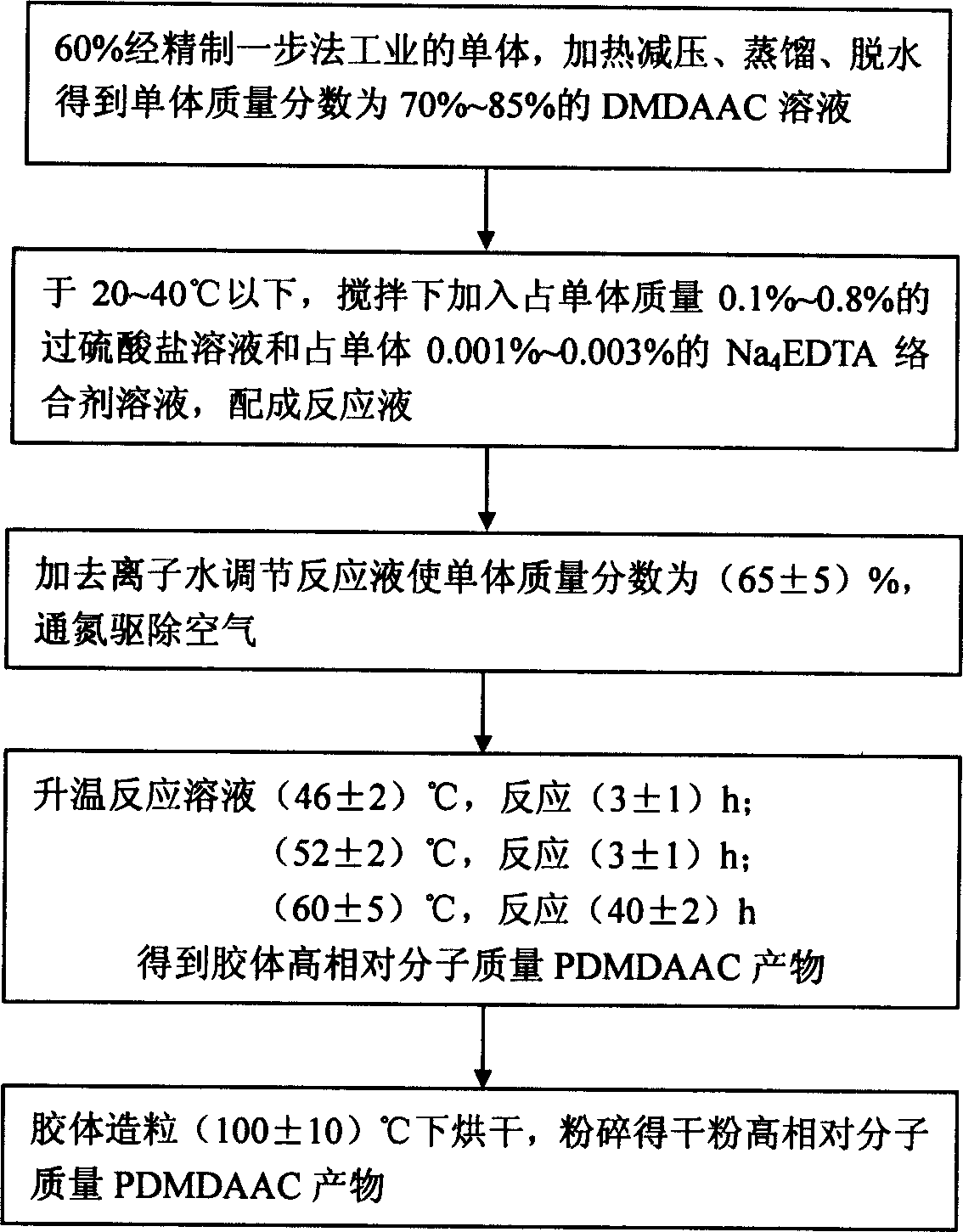

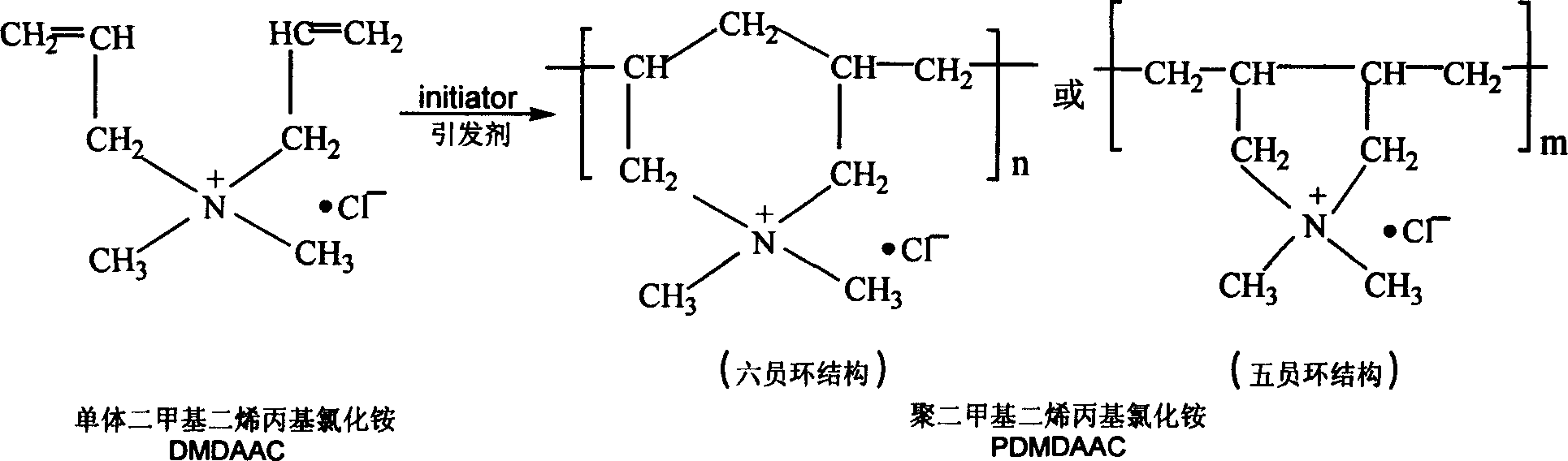

[0035] Embodiment 1: in conjunction with accompanying drawing, the specific embodiment of the preparation method of high relative molecular mass polydimethyldiallyl ammonium chloride is:

[0036] In the first step, the refined one-step industrial monomer DMDAAC solution with a mass fraction of 60% is used, and the main impurities contained in it are less than 1 mg / kg of allyl chloride, dimethylamine, allyl aldehyde, and allyl alcohol. Dimethylamine (tertiary amine) amount 19mg / kg, dimethylamine hydrochloride 700mg / kg, allyl dimethylamine hydrochloride (tertiary amine salt) 500mg / kg; sodium chloride amount 2000mg / kg, The amount of Fe and Cu ions is less than 1mg / kg. In the reactor, 33.5±0.5kg of monomer DMDAAC was heated and distilled under reduced pressure, and dehydrated to a mass fraction of 83.1%.

[0037] In the second step, add 100g of ammonium persulfate and Na 4 1.0 kg of aqueous solution of 2.0 g of EDTA, which accounts for about 0.35% and 0.0071% of the mass of the ...

Embodiment 2-5

[0041] Embodiment 2-5: in conjunction with accompanying drawing, process condition is the same as embodiment 1, is different from the substance content of embodiment 1, and its product performance result is listed in comparison table 1. Wherein MPS, APS, PPS and SPS are persulfate, ammonium persulfate, potassium persulfate and sodium persulfate respectively.

[0042] Table 1 Comparison of the preparation results of Examples 1-5

[0043] Preface

No

Raw material monomer (after dehydration)

Initiator dosage (accounting for monomer mass fraction, grams)

starting monomer

Content / %

product

PDMDAAC

[η] / dL / g

monomer conversion

/ %

Monomer content / %

Mass / kg

MPS / %(g)

Na 4 EDTA / %(g)

Example

1

83.1

33.5

(APS, ammonium salt)

0.35 (97.4)

0.0071(2.00)

65.0

3.99

99.0

Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com