Method for preparing vanillin molecular engram polymer

A technology of imprinting polymer and vanillin, which is applied in the separation/purification of carbonyl compounds, organic chemistry, etc., to simplify the production process, facilitate the separation effect, and facilitate the improvement of the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

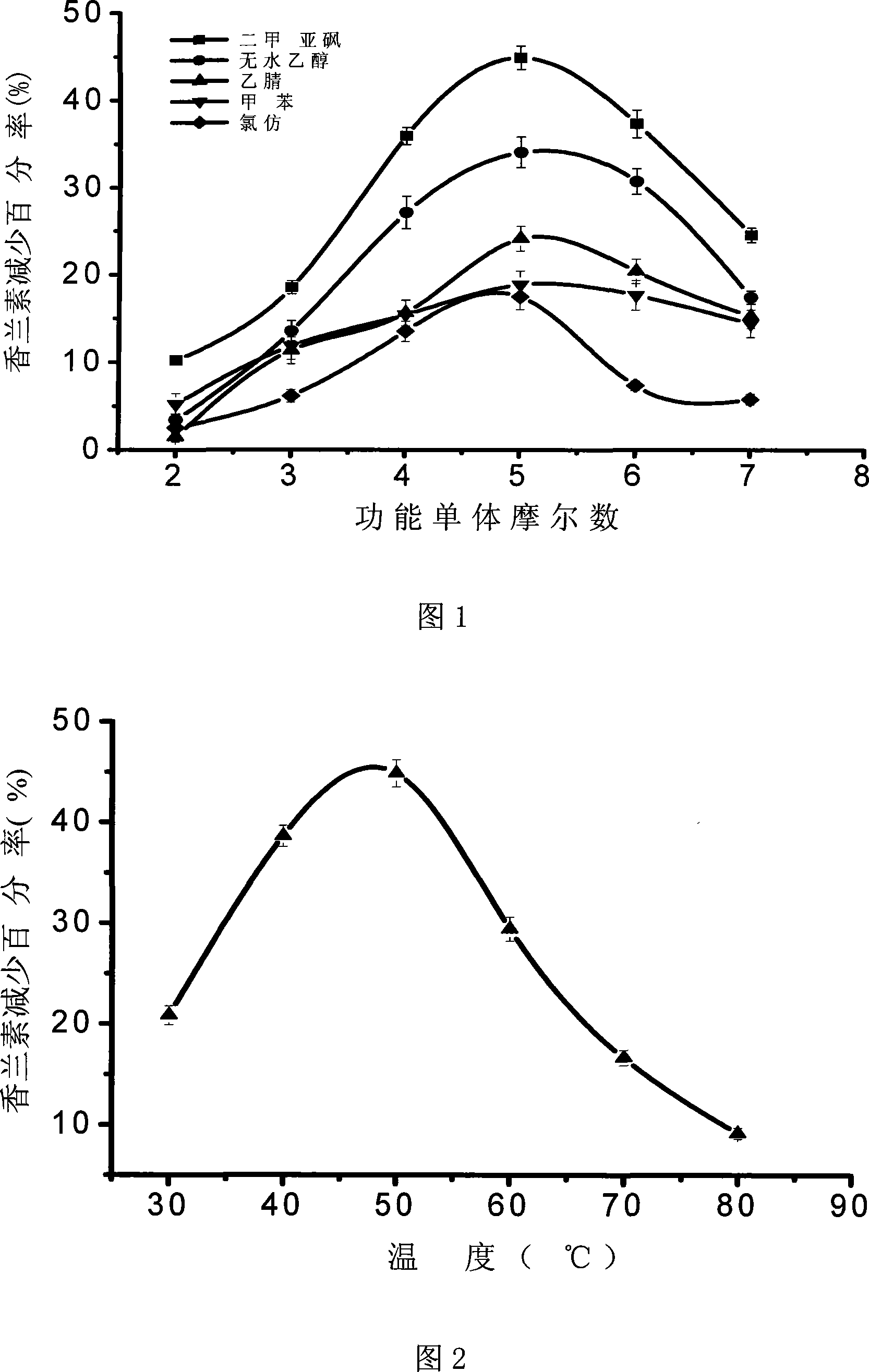

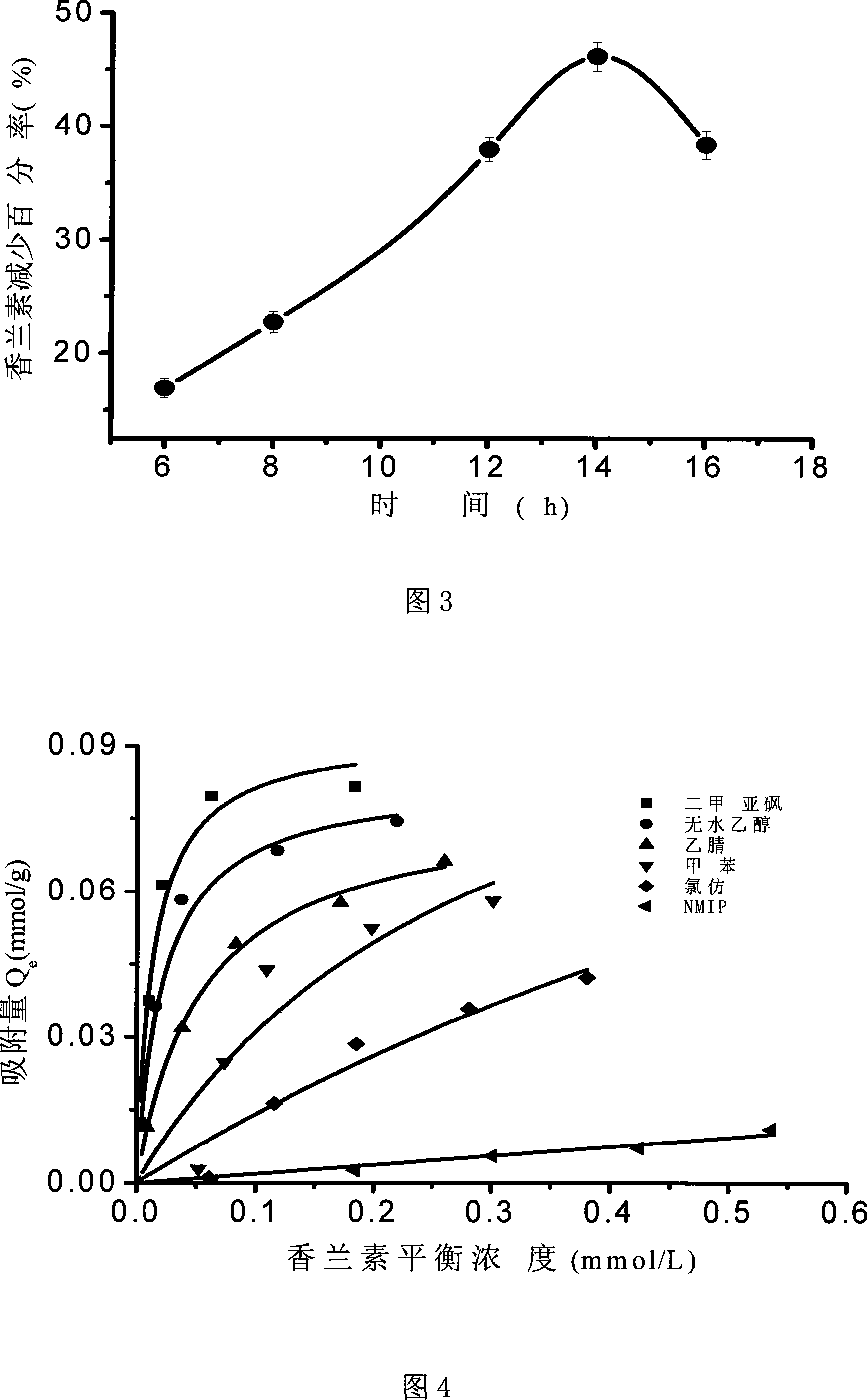

[0028] Weigh 1mmol of vanillin and 2mmol, 3mmol, 4mmol, 5mmol, 6mmol, 7mmol of methacrylamide functional monomer and dissolve them in 20mL of dimethyl sulfoxide solvent. After ultrasonic mixing for 15min, add 20mmol of N,N-methylene Based bisacrylamide cross-linking agent, ultrasonically mixed for 5 minutes, the molar ratios of template molecule: functional monomer: cross-linking agent were 1:2:20, 1:3:20, 1:4:20, 1:5: 20, 6 reaction systems of 1:6:20, 1:7:20; then add 5mL of emulsifier Tween-80 to each reaction system, ultrasonically mix for 10min, then add 0.25mmol of initiator azobisisobutyl Nitrile, then add 80mL dimethyl sulfoxide; blow nitrogen for 10min, seal, stir and heat in a water bath at 50°C at 300 rpm, react for 14h, and obtain a polymer containing vanillin.

[0029] Soaking and washing the polymer with dimethyl sulfoxide solvent is repeated 2 to 3 times to completely clean the vanillin remaining on the surface of the polymer. Naturally air-dried to obtain a sol...

Embodiment 2-1

[0031] Embodiment 2-1 dehydrated alcohol example

[0032]Weigh 1mmol of vanillin and 2mmol, 3mmol, 4mmol, 5mmol, 6mmol, 7mmol of methacrylamide respectively and dissolve them in 20mL of absolute ethanol solvent. After ultrasonic mixing for 15min, add 20mmol of cross-linking agent N,N-methylene Bisacrylamide, ultrasonically mixed for 5 minutes, to obtain template molecules: functional monomers: crosslinking agent 1:2:20, 1:3:20, 1:4:20, 1:5:20, 1:6:20, 6 reaction systems of 1:7:20. Add 5mL emulsifier Tween-80 to each system, ultrasonically mix for 10min, then add 0.25mmol initiator azobisisobutyronitrile, and add 80mL absolute ethanol. Nitrogen for 10 minutes, sealed. In a water bath at 50°C, stir and heat at a low speed, and react for 14 hours to obtain a polymer containing vanillin.

[0033] Soaking and washing the polymer with anhydrous ethanol solvent is repeated 2 to 3 times to completely clean the vanillin remaining on the surface of the polymer. Naturally air-dried t...

Embodiment 2-2

[0034] Embodiment 2-2 toluene example

[0035] Weigh 1mmol of vanillin and dissolve them in 20mL of toluene solvent with 2mmol, 3mmol, 4mmol, 5mmol, 6mmol, and 7mmol of methacrylamide respectively, and add 20mmol of cross-linking agent N,N-methylenebispropene after ultrasonic mixing for 15min Amide, ultrasonically mixed for 5min to obtain template molecules: functional monomers: crosslinking agent 1:2:20, 1:3:20, 1:4:20, 1:5:20, 1:6:20, 1: 6 reaction systems of 7:20. Add 5mL of emulsifier Tween-80 to each system, ultrasonically mix for 10min, then add 0.25mmol of initiator azobisisobutyronitrile, and add 80mL of toluene. Nitrogen for 10 minutes, sealed. In a water bath at 50°C, stir and heat at a low speed, and react for 14 hours to obtain a polymer containing vanillin.

[0036] Soaking and washing the polymer with toluene solvent is repeated 2 to 3 times to completely clean the vanillin remaining on the surface of the polymer. Naturally air-dried to obtain a solid polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com