Method for hydrolyzing soybean isoflavone by enzyme

A technology of soybean isoflavone and enzymatic hydrolysis, applied in the direction of fermentation, etc., can solve the problems of unrecyclable enzymes, difficult product separation, high cost and high cost, and achieve the effect of good industrial enlargement prospect and simple equipment and process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1, the preparation of immobilized β-glucosidase

[0056] 1. Preparation of immobilized β-glucosidase

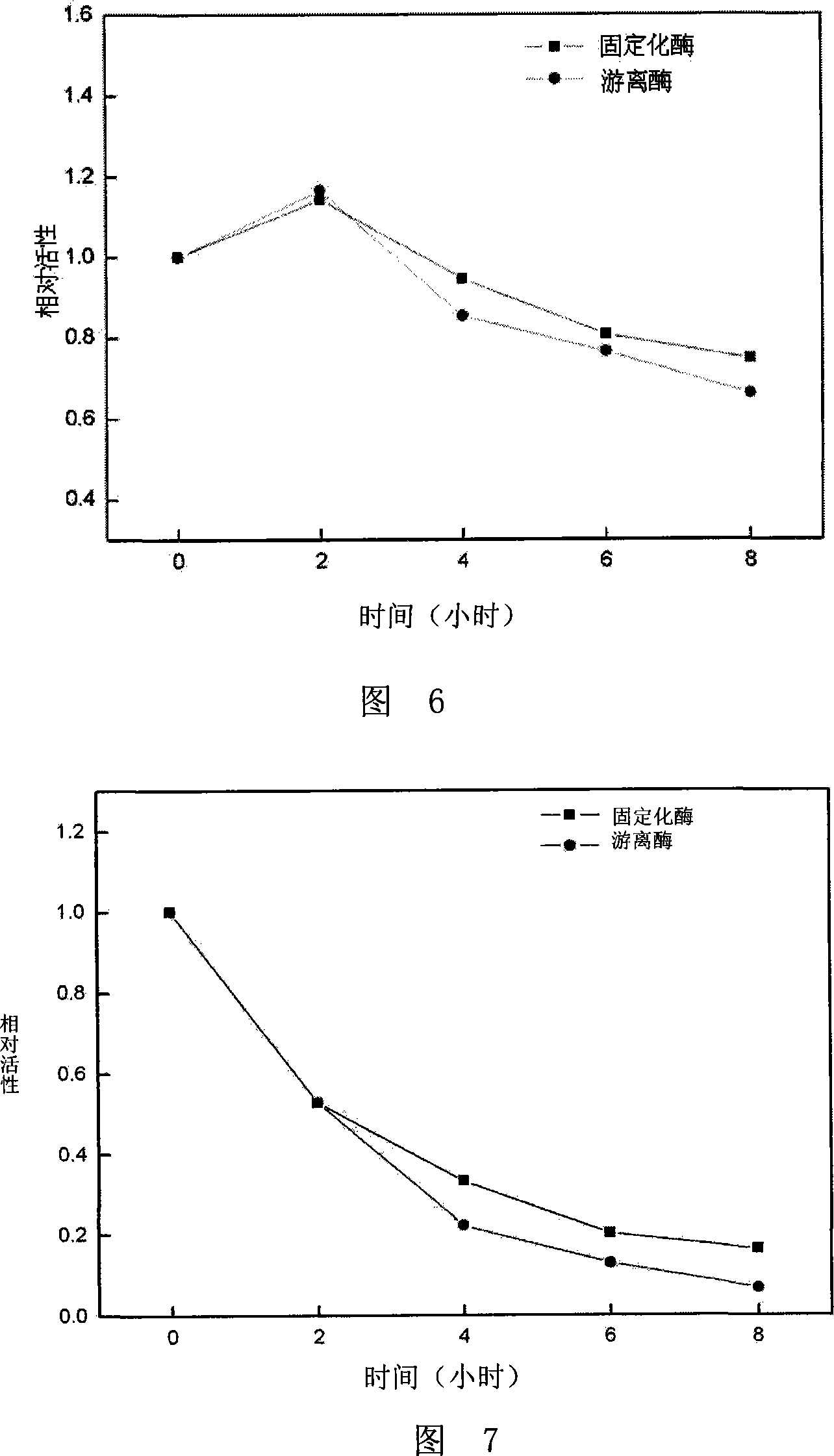

[0057] Prepare chitosan pellets with a diameter of about 2.5mm and very uniform according to the method described in the literature (Peng Zhiying, Yue Zhenfeng, Zhang Xuebing. Preparation of microsphere-shaped immobilized α-glucosidase. Journal of South China University of Technology (Natural Science Edition), 2001 , 29(6): 56-59 and Nitin W. Fadnavis, Gurrala Sheelu, Bezavada Mani Kumar. Gelatin Blends with Alginate: Gels for Lipase Immobilization and Purification, Biotechnol. Prog. 2003, 19: 557-564). The specific method is as follows: use 1% acetic acid by volume to prepare a 25g / 100ml chitosan solution, let it stand for 30 minutes, and use a suction tip to cooperate with a small funnel to make a dripping device as shown in Figure 3. The suction tip is Jill Mori 1ml and 200μl tips, the funnel is a 10ml small funnel.

[0058] Just below the distance of 2...

Embodiment 2

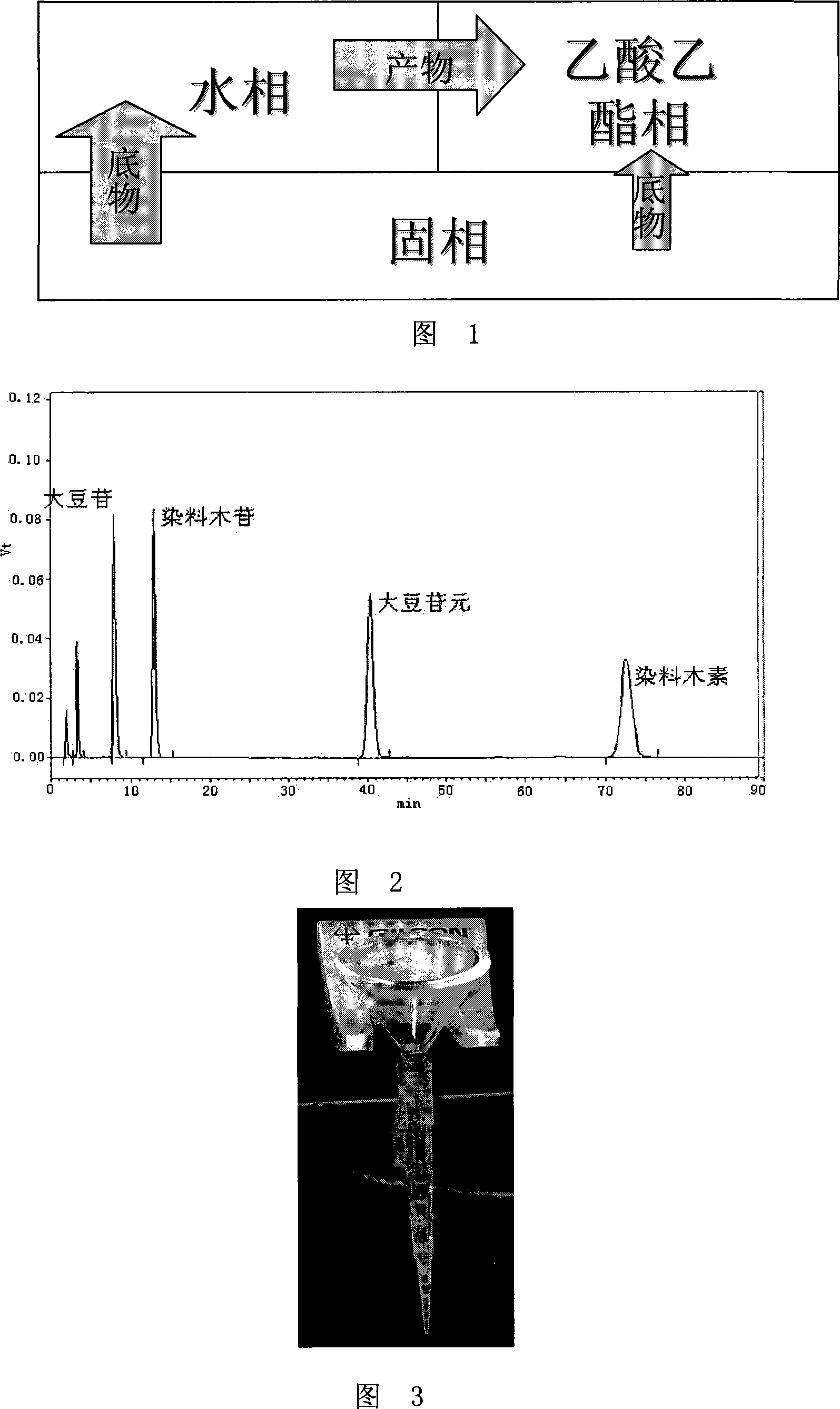

[0075] Embodiment 2, immobilized enzyme two-phase hydrolysis soybean isoflavones

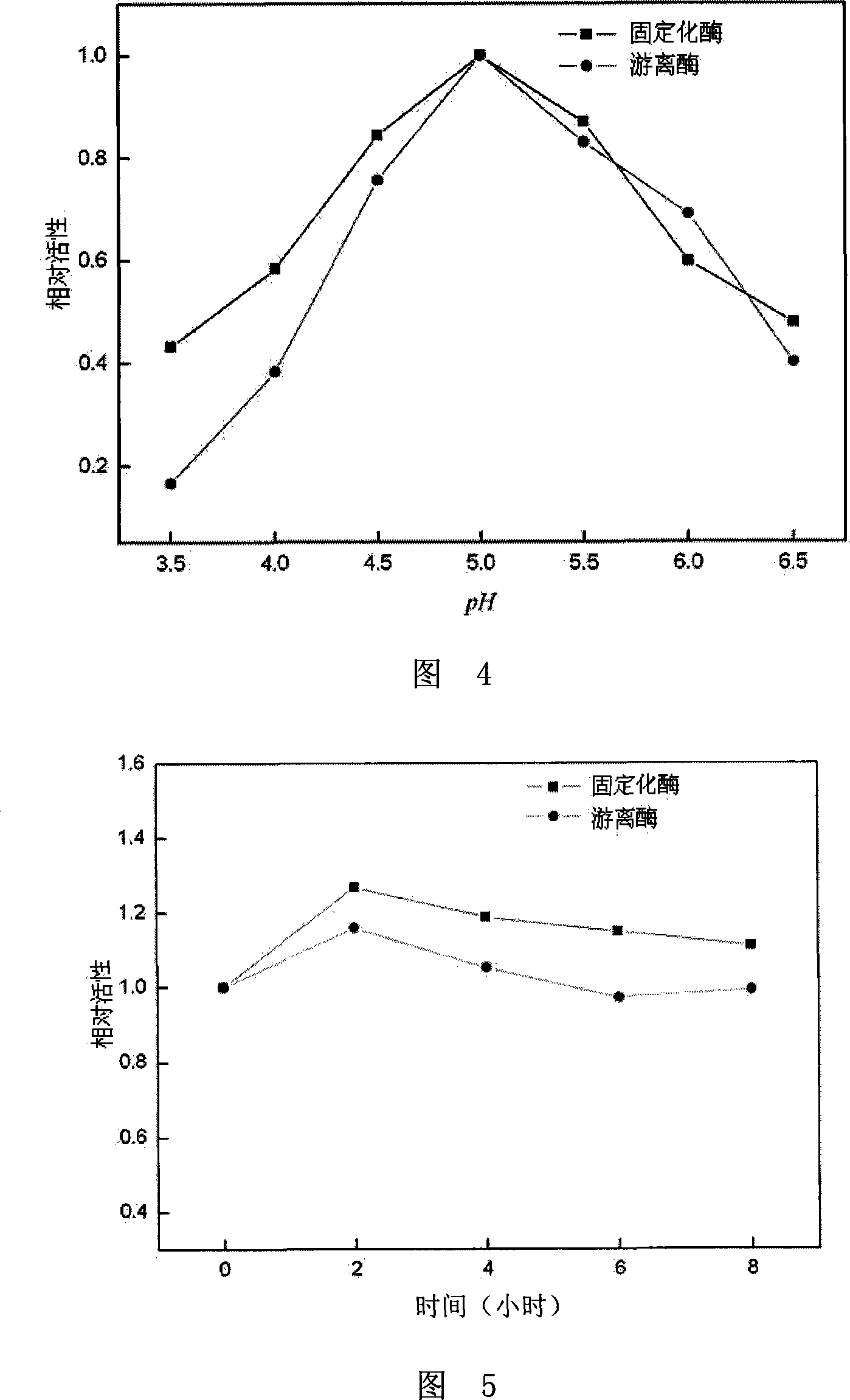

[0076] 14.8 mg of 30% strength soybean isoflavones and 1.48 U of immobilized β-glucosidase were added to 5 ml of 0.1 M pH=5 citric acid-sodium citrate buffer and 5 ml of ethyl acetate. The reactions were all carried out in a constant temperature shaker at 40° C. for three hours, and the contents of daidzin, genistin, daidzein and genistein were determined according to the above-mentioned HPLC method.

[0077] The results showed that the amount of daidzein obtained by the immobilized enzyme hydrolysis was 0.97mg, the amount of daidzein was 0.25mg at the initial stage of the reaction, and the amount of daidzein that should be obtained by the complete hydrolysis of daidzin was 0.96mg; The amount of genistein is 1.50 mg, the amount of genistein at the beginning of the reaction is 0.22 mg, and the amount of genistein that should be obtained by complete hydrolysis of genistein is 1.64 mg. According t...

Embodiment 3

[0078] Embodiment 3, application comparison of immobilized β-glucosidase in single-phase system and biphasic system

[0079] Two treatments were set up in the experiment, one of which was a single-phase system, and 14.8 mg of 30% soybean isoflavones and 1.48 U of immobilized β-glucose were added to 10 ml of 0.1M, pH=5 citric acid-sodium citrate buffer glycosidase; another treatment is a biphasic system, 14.8 mg of 30% specification soybean isoflavones and 1.48 U of immobilized β - Glucosidase. The reactions were all carried out in a constant temperature shaker at 40°C, samples were taken every hour, and the contents of daidzin, genistin, daidzein and genistein were determined according to the above-mentioned HPLC method, and the reaction was performed for three hours. The results are shown in Fig. 9 and Fig. 10, not only the product cannot be obtained in the single-phase system, but also the hydrolysis rate is slightly lower than that in the two-phase system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com