Micro-emulsification stainless steel cutting liquid

A technology of cutting fluid and stainless steel, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of inability to cut stainless steel and endanger workers' health, achieve excellent cooling performance, easy post-processing, and reduce downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

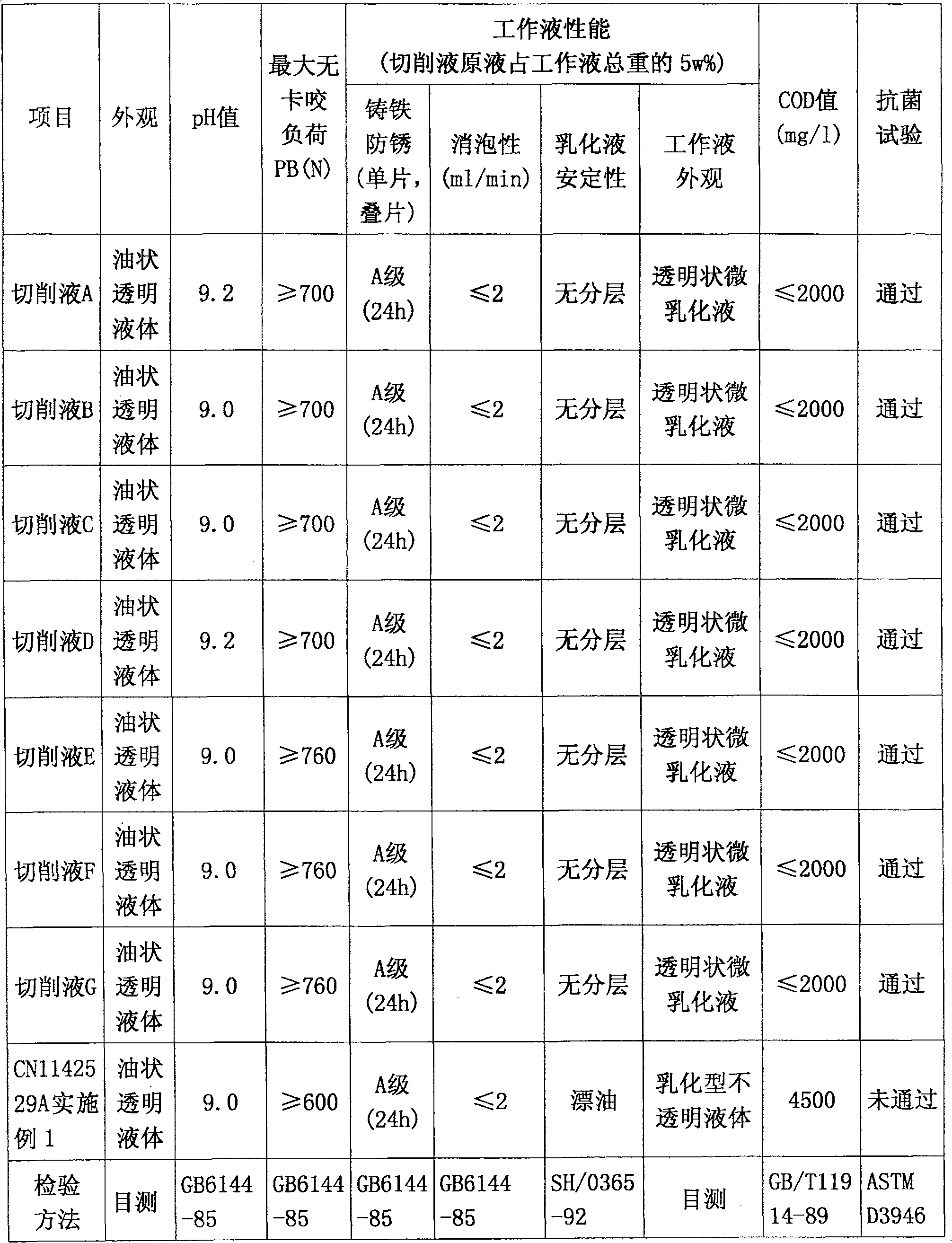

Examples

Embodiment 1

[0046] After mixing 9w% triethanolamine, 5w% monoethanolamine and 40w% water, add 5w% chlorinated paraffin, 10w% fatty alcohol polyoxyethylene ether (brand AEO-10), 5w% petroleum sulfonate sodium nitrate, 15w% oleic acid, 5w% pentaerythritol tetralaurate, 5w% mineral oil, 0.5w% benzotriazole, 0.5w% methyl silicone oil, stirred at 60°C for 30 Minutes, until completely transparent, no sediment, that is, the cutting fluid A (referring to the cutting fluid stock solution, the same as the following examples).

Embodiment 2

[0048] After mixing 21w% of triethanolamine, 3w% of monoethanolamine and 35w% of water, add 7w% of chlorinated paraffin, 5w% of fatty alcohol polyoxyethylene ether (AEO-10), 8w% of octanoic acid, 10w % oleic acid, 5w% pentaerythritol tetralaurate, 5.6w% mineral oil, 0.2w% benzotriazole, 0.2w% methyl silicone oil, stirred at a temperature of 60°C for 40 minutes until Completely transparent, no sediment, that is, the cutting fluid B is prepared.

Embodiment 3

[0050] After mixing 15w% triethanolamine, 4w% monoethanolamine and 38w% water, add 5w% chlorinated paraffin, 10w% fatty alcohol polyoxyethylene ether (AEO-10), 5w% dodecene Succinic acid, 15w% oleic acid, 2w% trimethylolpropane trilaurate, 5.2w% mineral oil, 0.5w% benzotriazole, 0.3w% methyl silicone oil, in Stir at a temperature of 55°C for 30 minutes until it is completely transparent and free of sediment, and the cutting fluid C is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com