Antibacterial agent for silk fibre and uses thereof and antimicrobial real silk fabric

An antibacterial agent and antibacterial technology, which is applied in the field of antibacterial silk fabrics, can solve the problems that are not suitable for antibacterial treatment of silk fibers or products, affect the dyeing color of the fabric surface, and greatly damage the fiber strength, so as to achieve no yellowing, Little change in color and obvious antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

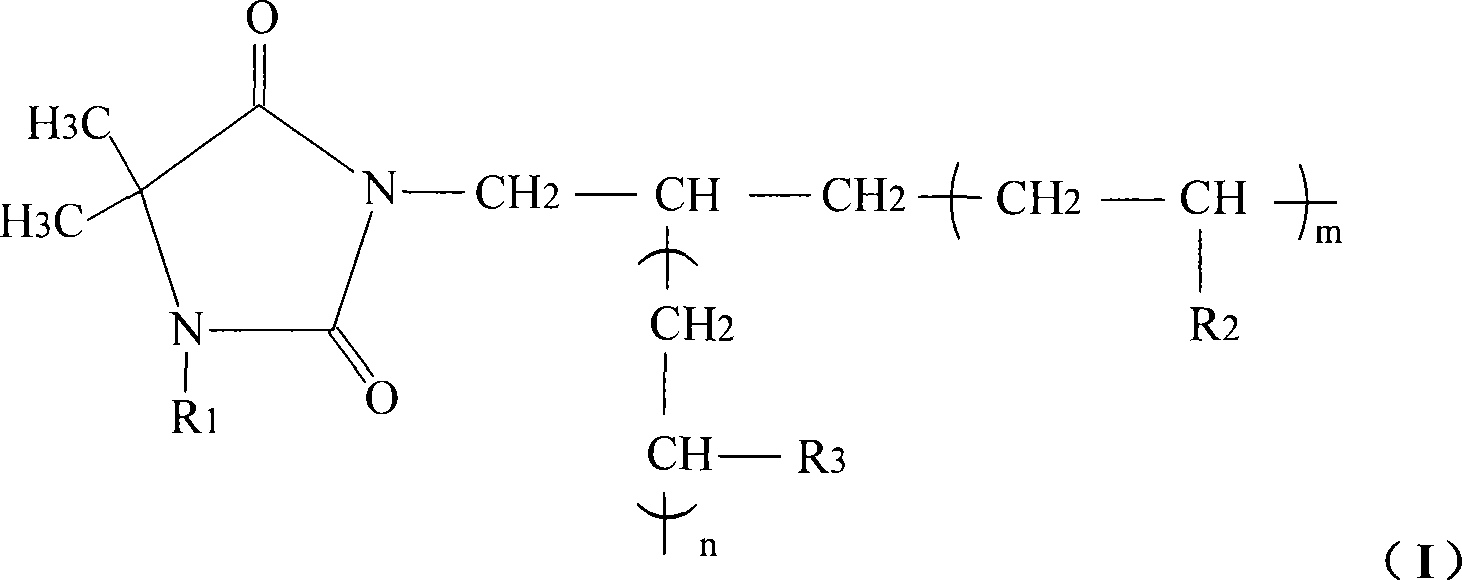

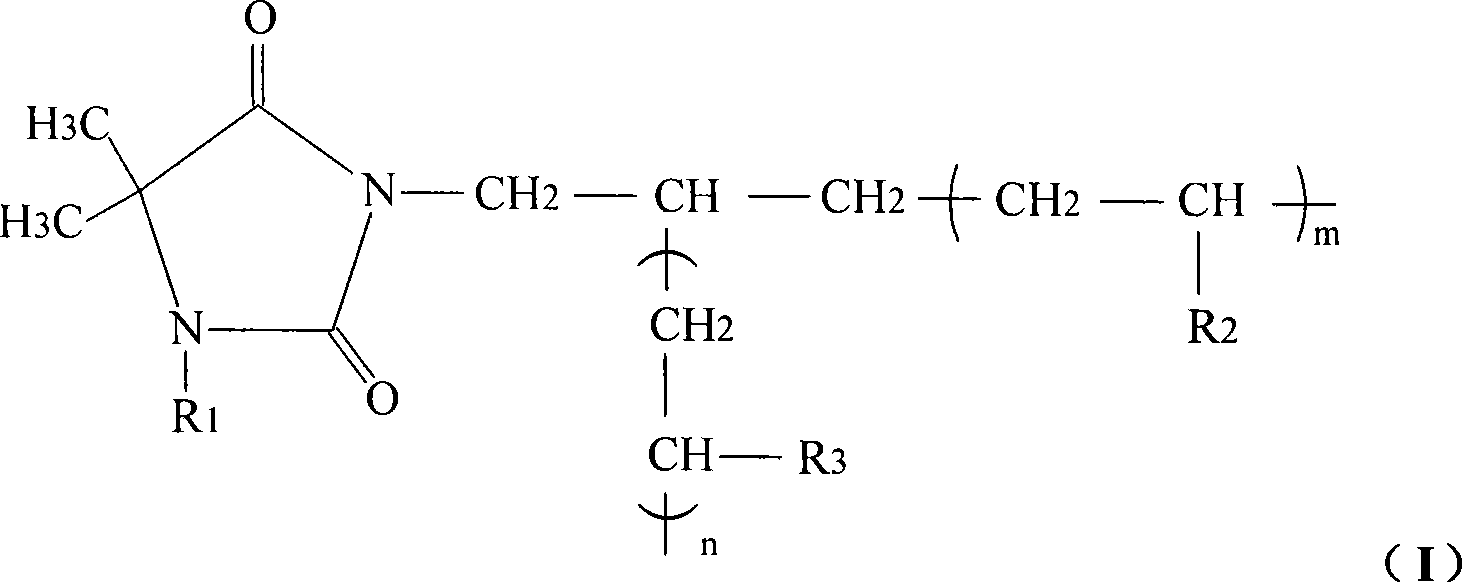

[0037] Dissolve 12.1 grams of allyl bromide in 20 grams of methanol solution, called component A; dissolve 12.8 grams of 5,5-dimethylhydantoin and 5.6 grams of potassium hydroxide in 50 grams of water, called component B ; Slowly add component A dropwise to component B while stirring, keep the temperature of the reaction system at 60°C, react for 2 hours and then cool down. At room temperature, the product was vacuum-dried to obtain 3-allyl-5,5-dimethylhydantoin.

[0038] Add 17.2 grams of 3-allyl-5,5-dimethylhydantoin, 53.0 grams of acrylonitrile, and 0.2 grams of ammonium persulfate into 100 grams of acidic water-soluble solution in a certain order, and keep the temperature of the reaction system at 70 ° C , reacted for 1 hour and then cooled. An allyldimethylhydantoin-acrylonitrile copolymer was obtained.

[0039] 50 grams of allyl dimethyl hydantoin-acrylonitrile copolymers are heated in alkaline solution to obtain allyl dimethyl hydantoin-acrylonitrile copolymers, A mixt...

Embodiment 2

[0042] The preparation method of 3-allyl-5,5-dimethylhydantoin is the same as that in Example 1.

[0043] Add 12.1 grams of 3-allyl-5,5-dimethylhydantoin, 44.5 grams of acrylonitrile, and 0.12 grams of ammonium persulfate into 100 grams of acidic water-soluble solution in a certain order, and keep the temperature of the reaction system at 75°C , reacted for 1 hour and then cooled. An allyldimethylhydantoin-acrylonitrile copolymer was obtained.

[0044] The hydrolysis and chlorination method of the cyano group in the allyl dimethyl hydantoin-acrylonitrile copolymer is the same as that in Example 1.

[0045] Prepare a solution of 25% allyl dimethyl hydantoin-acrylonitrile copolymer, 5% sodium chloride, and 1% softener, pad and pad real silk products, with a liquid rolling rate of 80%, and bake at 100°C to 110°C Dry to make antibacterial silk products.

Embodiment 3

[0047] The preparation method of 3-allyl-5,5-dimethylhydantoin is the same as that in Example 1.

[0048] Add 6.9 grams of 3-allyl-5,5-dimethylhydantoin, 29.7 grams of acrylonitrile and 0.11 grams of ammonium persulfate into 100 grams of acidic water-soluble , reacted for 1 hour and then cooled. An allyldimethylhydantoin-acrylonitrile copolymer was obtained.

[0049] The hydrolysis and chlorination method of the cyano group in the allyl dimethyl hydantoin-acrylonitrile copolymer is the same as that in Example 1.

[0050] Prepare a solution of 30% allyl dimethyl hydantoin-acrylonitrile copolymer and 2% softener, pad and pad real silk products with a liquid rolling rate of 80%, and dry at 100°C to 110°C to obtain antibacterial silk products.

[0051] The antibacterial silk products prepared by the above-mentioned three kinds of embodiments adopt the ASTM E2149-01 shaking flask test method to calculate the bacteriostatic rate, and the test conditions are: sample 1.0g, 50ml 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com