Sirolimus lipidosome freeze-dried acanthopanax powder and technique of preparing the same

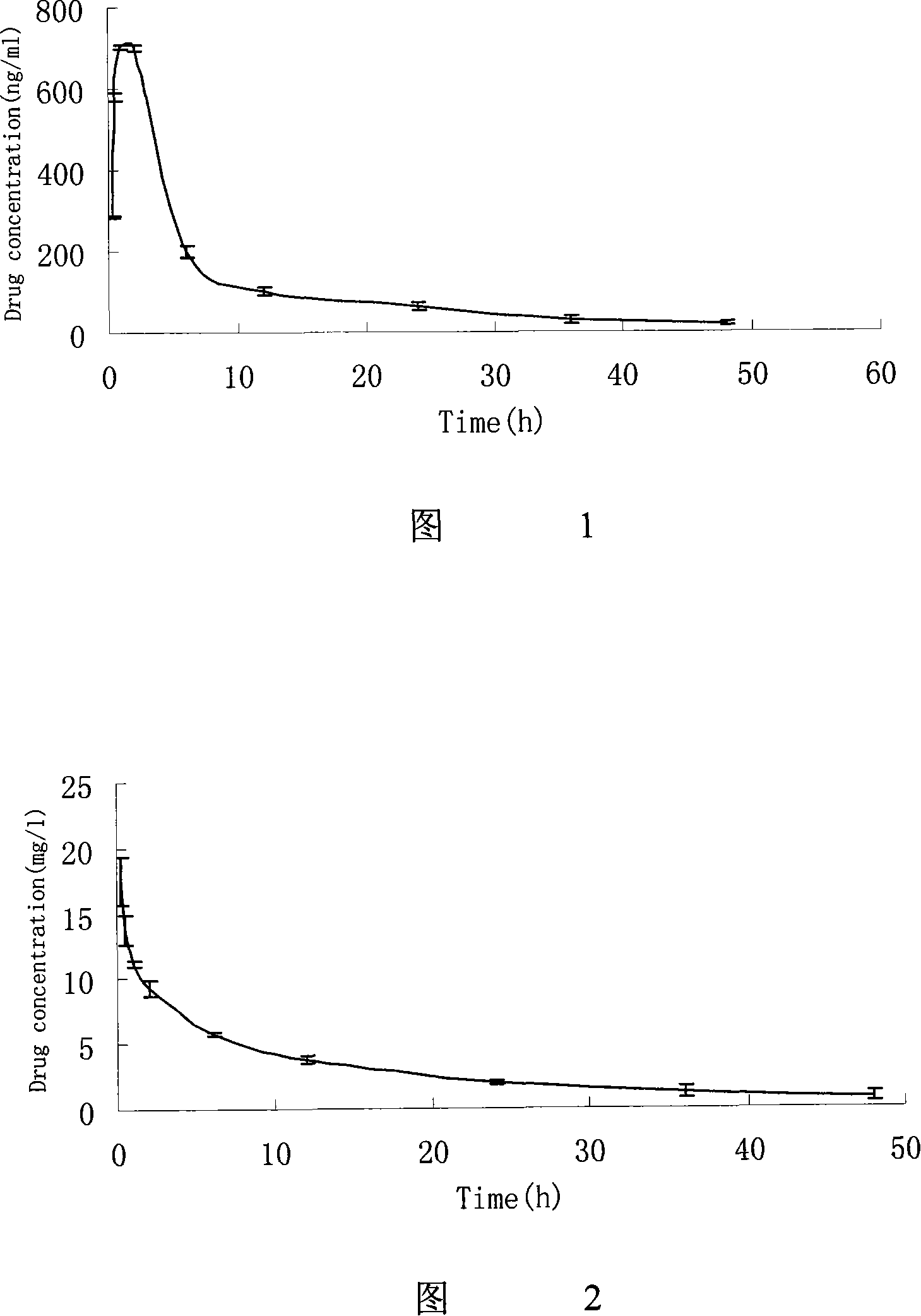

A technology for sirolimus liposome and freeze-dried powder injection, which is applied in the field of sirolimus liposome freeze-dried powder injection and its preparation technology, can solve the problems of low bioavailability of sirolimus and the like, and achieves prolonged blood circulation. Circulation time, improved efficacy, improved bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare raw materials with the following weights or volumes:

[0057] Sirolimus 500mg

[0058] Soy Lecithin 2.3g

[0059] Cholesterol 1g

[0060] Vitamin E 21mg

[0061] Phosphate buffer (p H7.4, 0.01mol / L) 300ml

[0062] Mannitol 100g

[0063] Chloroform 400ml

[0065] Water for injection 1000ml

[0066] Dissolve sirolimus, phospholipids, cholesterol, and vitamin E in chloroform according to the weight ratio of raw materials in the formula and mix uniformly; remove the organic solvent in the solution under reduced pressure with a rotary evaporator (temperature is not higher than 40° C.), and A lipid film is formed on the glass bottle wall; add 300ml of isotonic phosphate buffer (pH6-7.4, 0.01mol / L, containing 0.9% Nacl), stir for 30min, and place it at room temperature for 2h to make the film imbibition; Stir at room temperature for 2 hours to obtain an aqueous liposome suspension; the obtained aqueous liposome suspension is processe...

Embodiment 2

[0068] Prepare raw materials with the following weights or volumes:

[0069] Sirolimus 1000mg

[0071] Distearoylphosphatidylcholine 5g

[0072] Cholesterol 7g

[0073] Vitamin E 100mg

[0074] Phosphate buffer (p H7.4, 0.01mol / L) 300ml

[0075] Mannitol 150g

[0076] Chloroform 500ml

[0078] Water for injection 1000ml

[0079] Sirolimus, phospholipid, cholesterol, vitamin E are dissolved in 2: 1 chloroform-ethanol mixed solvent according to the weight ratio of raw material in the formula and mix homogeneously; With rotary evaporator, the organic solvent in the solution is removed under reduced pressure (temperature not higher than 40°C), a lipid film is formed on the glass bottle wall; add 300ml of isotonic phosphate buffer (p H6-7.4, 0.01mol / L, containing 0.9% Nacl), stir for 30min, and place at room temperature 2h, make film imbibition; Stir at room temperature 2h again, obtain liposome water suspension; 0...

Embodiment 3

[0081] Prepare raw materials with the following weights or volumes:

[0082] Sirolimus 1000mg

[0083] Soy Lecithin 3g

[0084] Distearoylphosphatidylcholine 5g

[0085] Cholesterol 7g

[0086] Vitamin E 100mg

[0087] Phosphate buffer (pH7.4, 0.01mol / L) 300ml

[0088] Mannitol 150g

[0089] Chloroform 500ml

[0091] Water for injection 1000ml

[0092] Sirolimus, phospholipid, cholesterol, vitamin E are dissolved in 2: 1 chloroform-ethanol mixed solvent according to the weight ratio of raw material in the formula and mix homogeneously; With rotary evaporator, the organic solvent in the solution is removed under reduced pressure (temperature Not higher than 40°C), a lipid film is formed on the glass bottle wall; add 300ml of isotonic phosphate buffer (pH6-7.4, 0.01mol / L, containing 0.9% Nacl), stir for 30min, and place at room temperature for 2h , to make the film imbibition; then stirred at room temperature for 2 hours to obtain an aqueous li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com