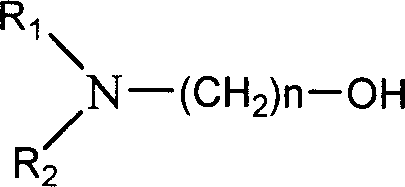

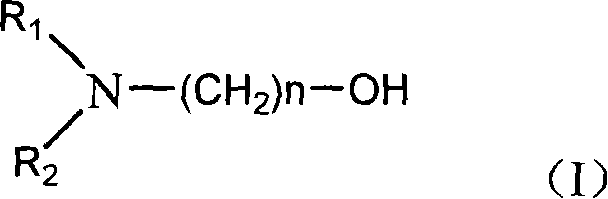

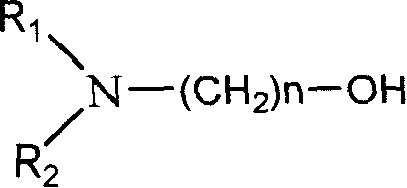

Method for preparing carboxylate by dehydrogenating carbinol with modified amorphous copper metal catalyst

An amorphous alloy and amorphous technology, which is applied in the field of modified amorphous copper alloy catalyst to dehydrogenate primary alcohol to prepare carboxylate, can solve the problem of low catalyst load, poor activity and selectivity, and large amount of catalyst used. problems, to achieve the effect of reducing catalyst consumption, high activity and stability, and high industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1: the preparation of amorphous copper catalyst

[0086] This example illustrates the preparation of a copper-aluminum-iron catalyst. Add 57.5 grams of copper, 41.3 grams of aluminum, and 1.2 grams of iron into the quartz tube, heat it in a high-frequency furnace to above 1300 ° C to melt it, and make it alloy, and then use an inert gas to pour the alloy liquid out of the quartz tube The nozzle is sprayed onto a copper roller with a rotating speed of 800 rpm. Cooling water is passed through the copper roller. After rapid cooling, the alloy liquid is thrown out along the tangent of the copper roller to form scale-like strips. The scale-like strips are ground to The particle diameter is below 1000 microns, resulting in a master alloy. The master alloy is heat-treated in a hydrogen environment, the temperature of the heat treatment is 600° C., and the constant temperature time is 3 hours. The heat-treated master alloy was slowly added into a three-necked flask...

Embodiment 2

[0087] Embodiment 2: the preparation of adding nickel, chromium, zirconium modified amorphous copper catalyst

[0088] The catalyst of the present invention was prepared according to the steps of Example 1, except that the proportion of the catalyst was different. Add 56.4 grams of copper, 40.5 grams of aluminum, 0.2 grams of iron, 0.6 grams of zirconium, 0.3 grams of chromium, and 2 grams of nickel into the quartz tube, heat it in a high-frequency furnace to above 1300 ° C and melt it to alloy it, and then Use inert gas to spray the alloy liquid from the nozzle under the quartz tube onto a copper roller with a rotating speed of 800 rpm. Cooling water is passed through the copper roller. After rapid cooling, the alloy liquid is thrown out along the tangent of the copper roller to form scales. The scale-shaped strips and the scale-shaped strips are ground to a particle diameter of less than 1000 microns to obtain the master alloy. The remaining steps are the same as Example 1....

Embodiment 3

[0089] Embodiment 3: the preparation of adding nickel, chromium, iron, zirconium, molybdenum, phosphorus modified amorphous copper catalyst

[0090] The catalyst of the present invention was prepared according to the steps of Example 1, except that the proportion of the catalyst was different. Add 55.0 grams of copper, 40.1 grams of aluminum, 0.2 grams of iron, 0.1 grams of zirconium, 0.8 grams of chromium, 2 grams of nickel, 0.5 grams of molybdenum, and 1.5 grams of red phosphorus into the quartz tube, and heat it to 1300 ° C in a high frequency furnace The above is melted to make it alloyed, and then the alloy liquid is sprayed from the nozzle under the quartz tube to a copper roller with a rotation speed of 800 rpm with an inert gas. Cooling water is passed through the copper roller, and the alloy liquid is rapidly cooled. Throw it out along the tangent of the copper roll to form scale-like strips, and grind the scale-like strips to a particle diameter of less than 1000 mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com