Plasminogen and cultivation method therefor

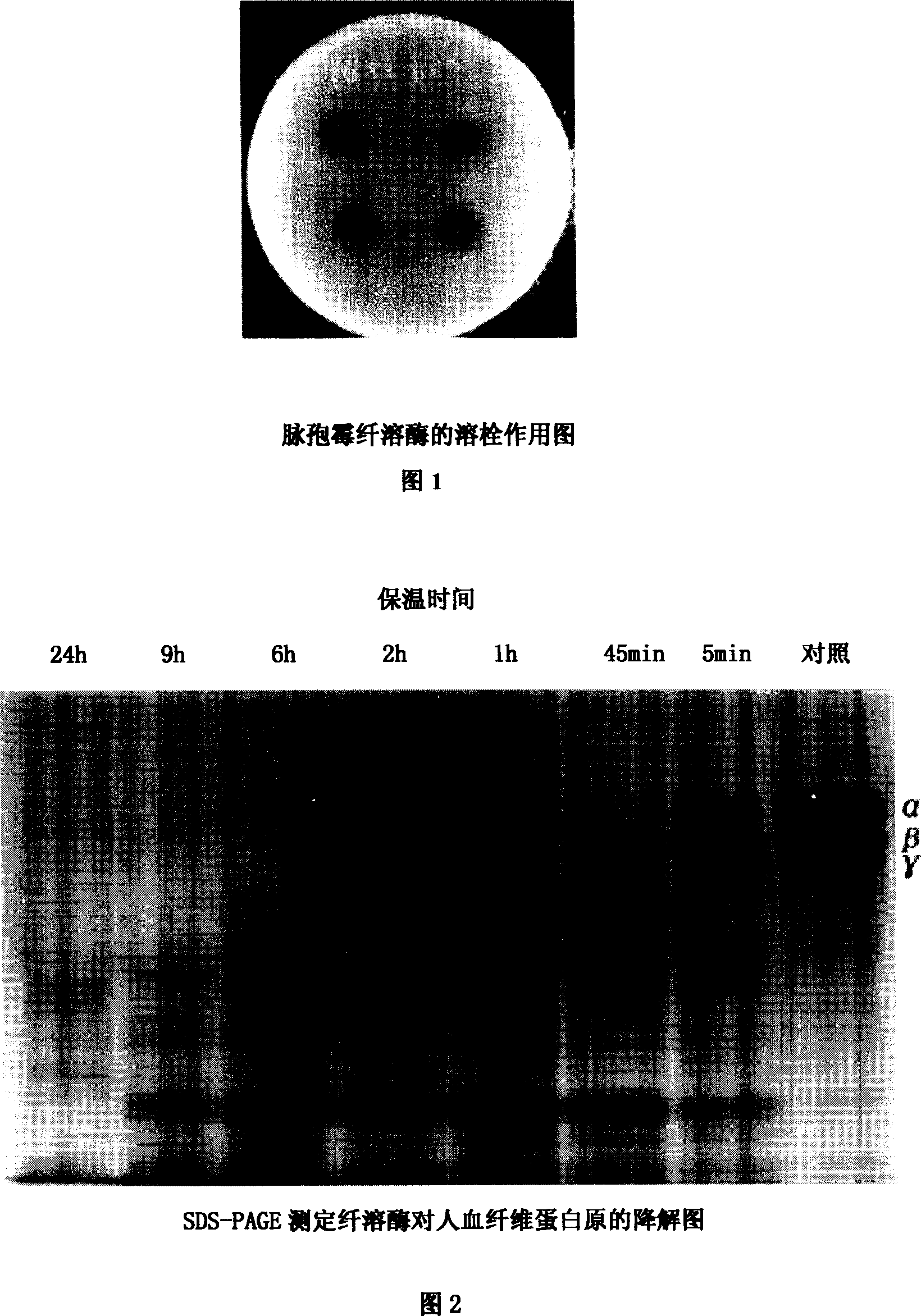

A technology for plasmin and bacterial species, applied in the field of plasmin, can solve the problems of high technical requirements, great difficulty, side effects such as bleeding, etc., and achieve the effects of low cost of raw materials and good thrombolytic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Strain: Neurospora sitophlia No. 17 Neurospora good food

[0026] 2. Medium and culture conditions:

[0027] (1) Slant medium (PDA slant): 2% glucose, 2% agar, prepared with 20% potato juice, natural pH, cultured at 28°C for 3 days.

[0028] (2) Nystatin resistance primary screening plate medium: 10U / ml nystatin in the slant medium, 0.02% (w / v) into LiCl·H 2 O, 0.08 (w / v) sodium deoxycholate, incubated at 25-28°C for 36 hours;

[0029] (3) Solid fermentation medium for double screening: bean dregs: bran=4:1 (dry weight ratio), CaCl 2 0.75%, FeSO 4 ·7H 2 O 0.045%, natural pH, inoculum size 5×10 5 pc / bottle, ferment for 3 days at 28-30°C.

Embodiment 2

[0031] 1. Incline cultivation is the same as in Example 1

[0032] 2. Solid fermentation culture: The composition of the shake flask fermentation medium is: bean dregs: bran (4:1)+CaCl 2 0.75%+FeSO 4 ·7H 2 O 0.045%. Each bottle of medium was inoculated with 3.4×10 5 1 spore, cultivated in a 28°C incubator for 48 hours, and then leached with normal saline for 4-6 hours.

[0033] 3. Separation and purification of plasmin: After the solid fermentation product is leached with normal saline, it undergoes 40-80% saturation ammonium sulfate graded salting-out, Octyl-SepharoseFF hydrophobic interaction chromatography, SP-SepharoseHP ion-exchange chromatography, Phenyl hydrophobic interaction chromatography and RESOURCE hydrophobic interaction chromatography collect fibrinolytic active ingredients.

Embodiment 3

[0035] 1. Incline cultivation is the same as in Example 1

[0036] 2, solid fermentation is the same as embodiment 2 shallow dish fermentation;

[0037]3. Separation and purification of plasmin: Neurospora solid fermentation broth was extracted with physiological saline, 40-80% ammonium sulfate graded salting out, and Octyl-Sepharose FF hydrophobic interaction chromatography and Sephadex G-25 gel filtration were used. Chromatography, SP-SepharoseHP strong cation exchange chromatography, Superdex75 gel filtration chromatography, collected fibrinolytic active components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com