Phosphor for GaN based light-emitting diode and method for preparing same

A technology of light-emitting diodes and phosphors, which is applied in the field of white light LEDs, can solve the problems of undiscovered, matching excitation wavelengths of phosphors, and can not well satisfy UV-LEDs, etc., and achieves the effect of broadening the emission spectrum.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

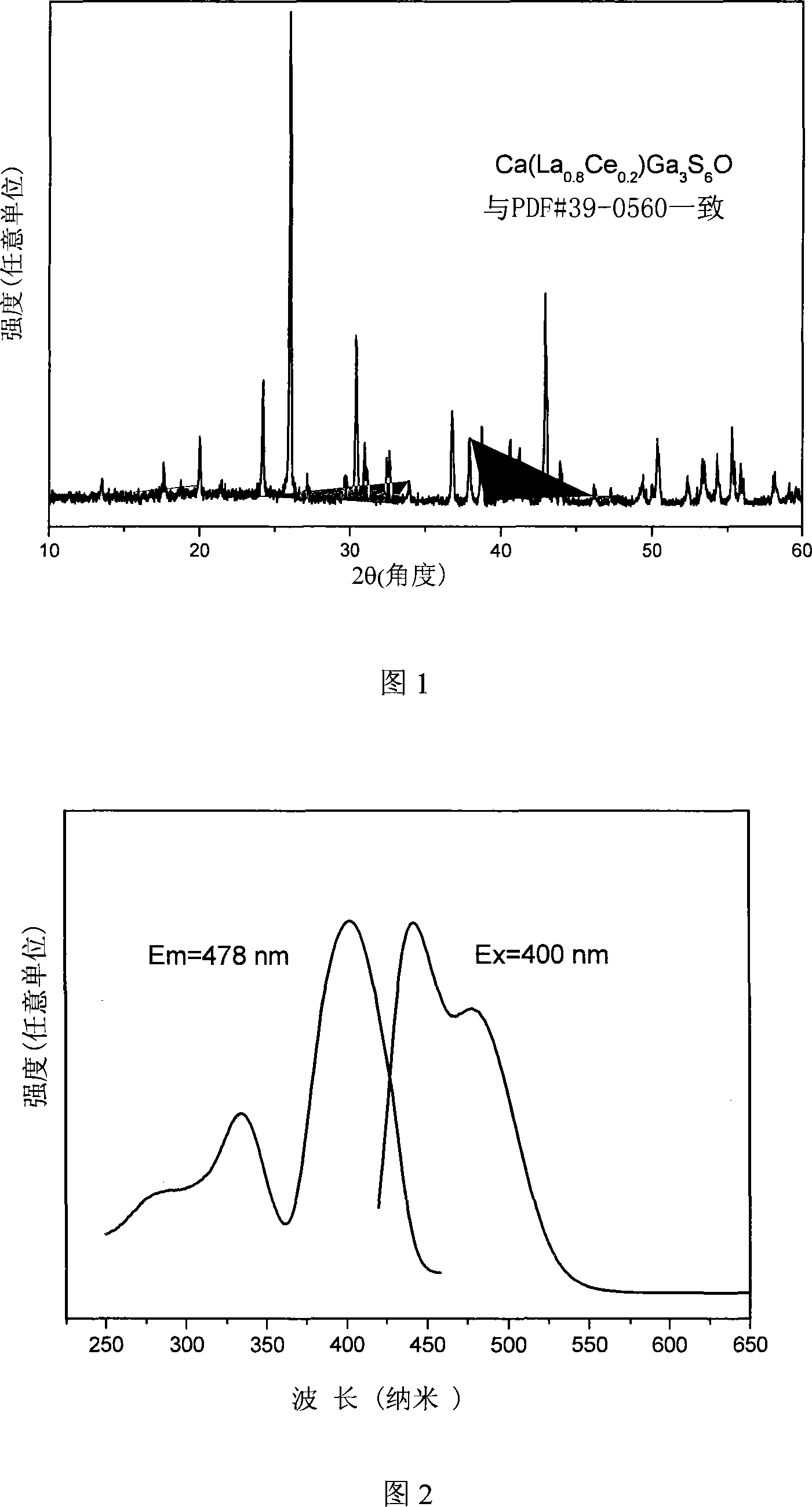

[0026] Example 1: Ca(La 0.8 Ce 0.2 ) Ga 3 S 6 Synthesis of O phosphor powder:

[0027] CaCO 3 (analytical pure) 0.1122 grams;

[0028] La 2 S 3 0.2992 grams;

[0029] Ga2 S 3 0.7069 grams;

[0030] Ce 2 S 3 0.0753 grams;

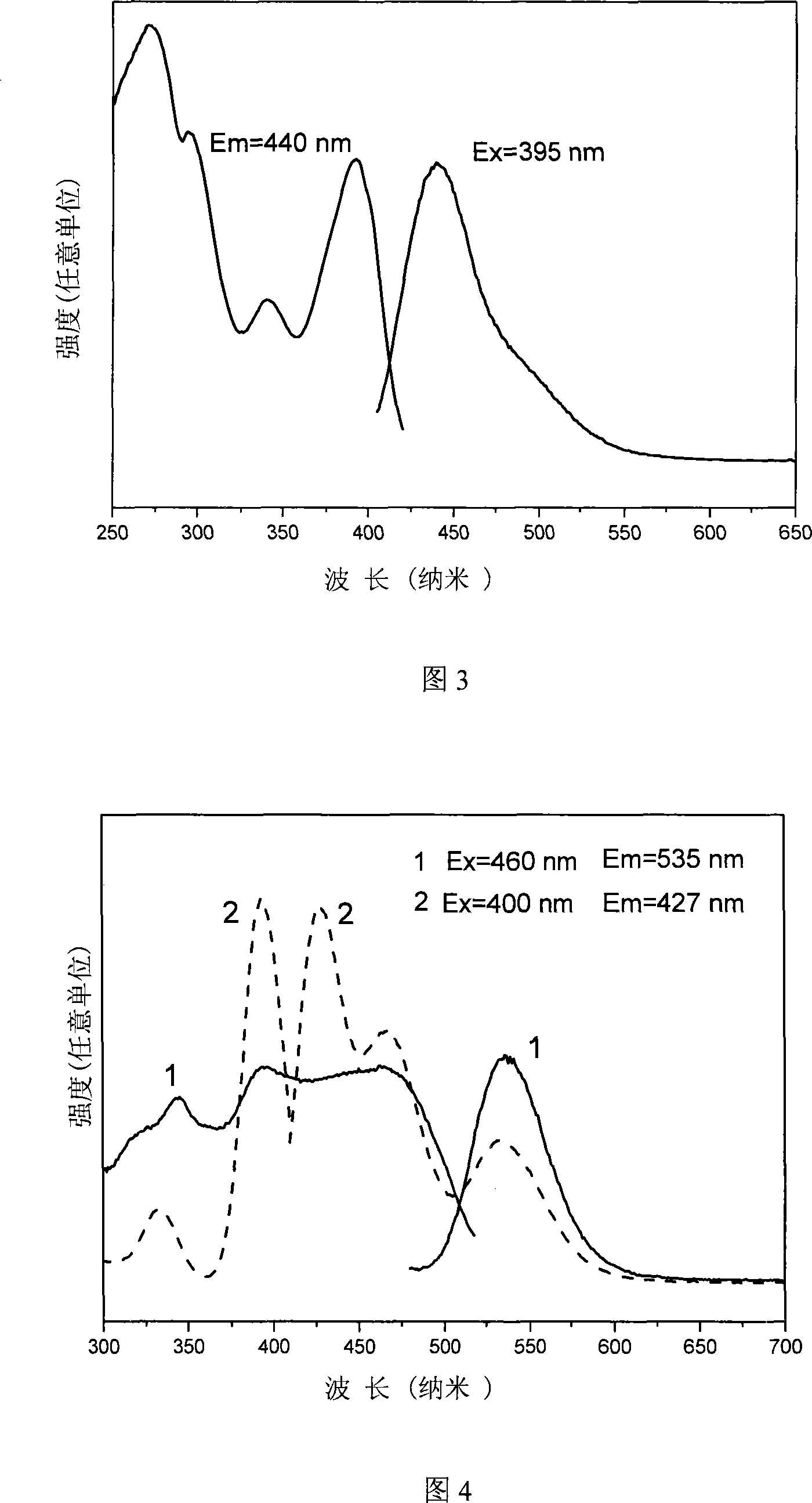

[0031] La 2 o 3 (99.99%), CeO 2 (99.99%) at 1200°C, reducing gas CS 2 Burning for 3 to 4 hours at lower temperature to obtain La 2 S 3 , Ce 2 S 3 Raw materials; the Ga 2 o 3 (analytical pure) at 900 ° C, reducing gas CS 2 Ignite for 2 to 3 hours to obtain Ga 2 S 3 raw material. Weigh the obtained raw materials according to the above composition, grind and mix them in an agate mortar, put them into a corundum crucible, pass nitrogen gas to drive out the air in the quartz tube before heating, sinter at 920°C for 3.5 hours in a nitrogen atmosphere, and cool Finally, grind evenly, pulverize and sieve to finally get the product. The X-ray diffraction pattern of the phosphor powder is shown in Figure 1, which is consistent wi...

Embodiment 2

[0032] Embodiment 2: Ba(Y 0.95 Ce 0.05 ) Ga 3 S 6 Synthesis of O phosphor powder:

[0033] BaCO 3 (analytical pure) 0.3946 grams;

[0034] Y 2 S 3 0.2603 grams;

[0035] Ga 2 S 3 0.7069 grams;

[0036] Ce 2 S 3 0.0188 grams;

[0037] Will Y 2 o 3 (99.99%), CeO 2 (99.99%) at 1200°C, reducing gas CS 2 Burn for 3 to 4 hours to get Y 2 S 3 , Ce 2 S 3 Raw materials; the Ga 2 o 3 (analytical pure) at 900 ° C, reducing gas CS 2 Ignite for 2 to 3 hours to obtain Ga 2 S 3 raw material. Weigh the obtained raw materials according to the above composition, grind and mix them in an agate mortar, put them into a corundum crucible, pass nitrogen gas to drive out the air in the quartz tube before heating, sinter at 950°C for 2 hours in a nitrogen atmosphere, and cool Finally, grind evenly, pulverize and sieve to finally get the product. The sample is excited under 395nm ultraviolet light and emits blue light. Excitation and emission spectra at room te...

Embodiment 3

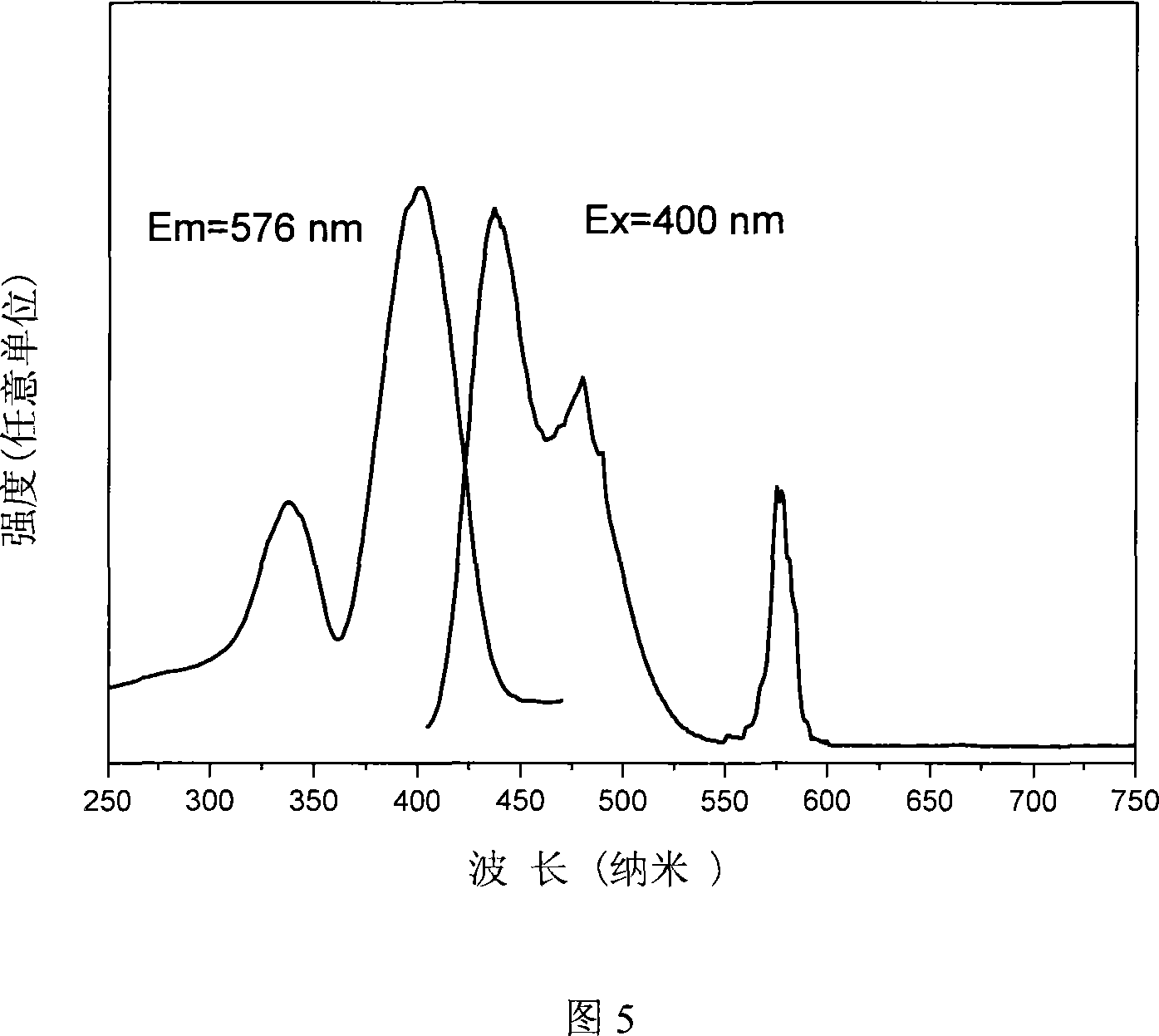

[0038] Embodiment 3: Sr(La 0.94 Ce 0.03 Eu 0.03 ) Ga 3 S 6 Synthesis of O phosphor powder:

[0039] SrO (analytical pure) 0.2072 grams;

[0040] La 2 S 3 0.3516 grams;

[0041] Ga 2 S 3 0.7069 grams;

[0042] Ce 2 S 3 0.0113 grams;

[0043] EuS 0.0110 g;

[0044] La 2 o 3 (99.99%), CeO 2 (99.99%), Eu 2 o 3 (99.99%) at 1200°C, reducing gas CS 2 Burning for 3 to 4 hours at lower temperature to obtain La 2 S 3 , Ce 2 S 3 , EuS raw material; the Ga 2 o 3 (analytical pure) at 900 ° C, reducing gas CS 2 Ignite for 2 to 3 hours to obtain Ga 2 S 3 raw material. Weigh the obtained raw materials according to the above composition, grind and mix them in an agate mortar, put them into a corundum crucible, pass in argon gas to drive out the air in the quartz tube before heating, and sinter at 850°C for 3 hours in an argon atmosphere , after cooling, grind evenly, crush and sieve, and finally get the product. The sample is excited under 400nm ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com