Ultra-hydrophilic self-cleaning anti-fog coat and its preparation method and use

An anti-fog coating and self-cleaning technology, which is applied in the field of nanomaterial preparation, can solve the problems of high energy consumption, difficult to achieve, complicated devices, etc., and achieves the effects of simple equipment, good anti-fog performance, and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

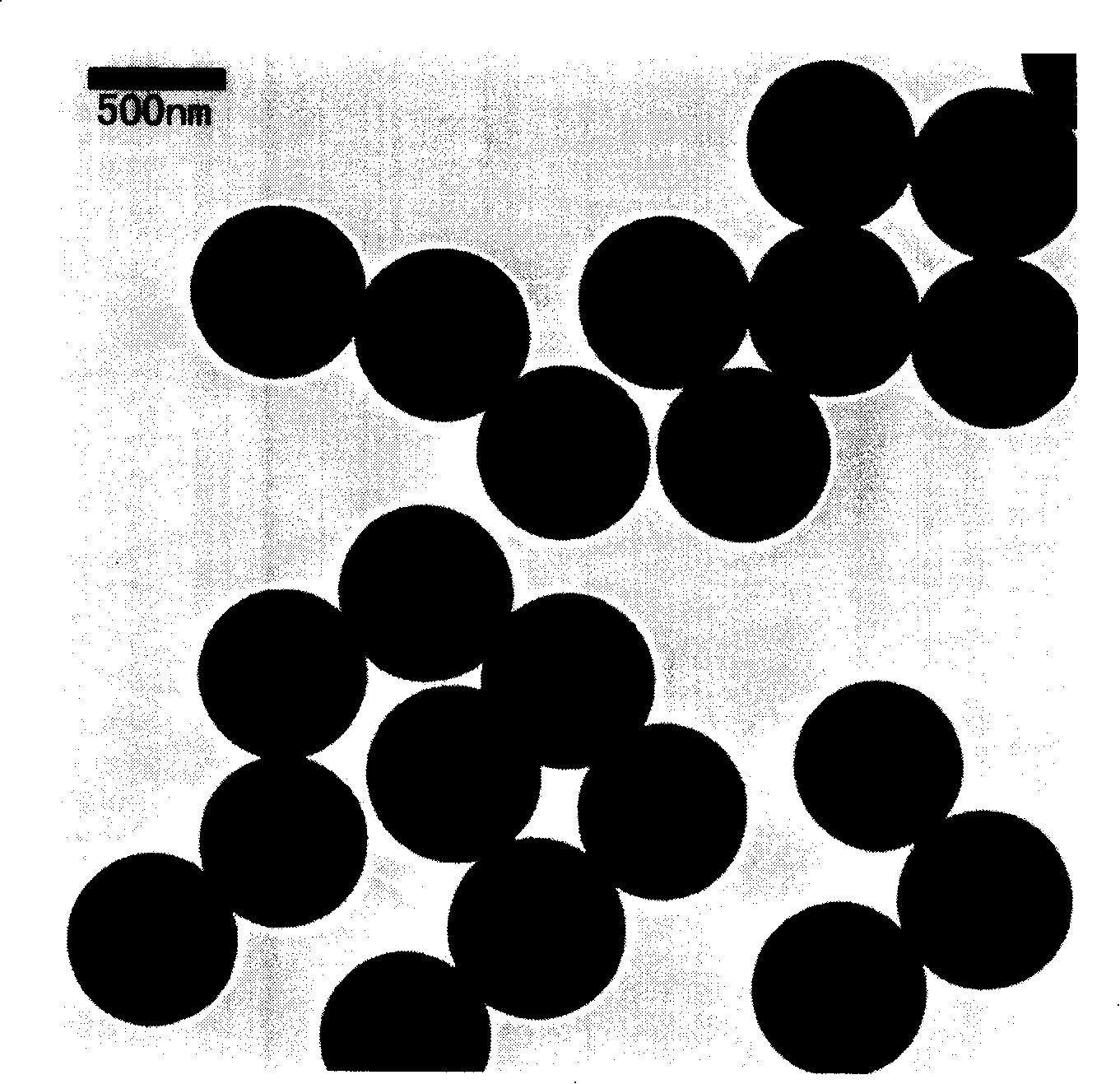

[0044] Preparation of large spherical particles: Add 63.6mL pure water, 147.6mL absolute ethanol, and 9.0mL ammonia water into the Erlenmeyer flask, stir magnetically at room temperature for half an hour, then add 9.8mL tetraethyl orthosilicate (TEOS) dropwise under stirring Continue to stir at room temperature for 12-15 hours to obtain a white suspension, and the resulting SiO with a diameter of about 300-800nm 2 Transmission electron microscope pictures of spherical macroparticles are as follows figure 1 shown.

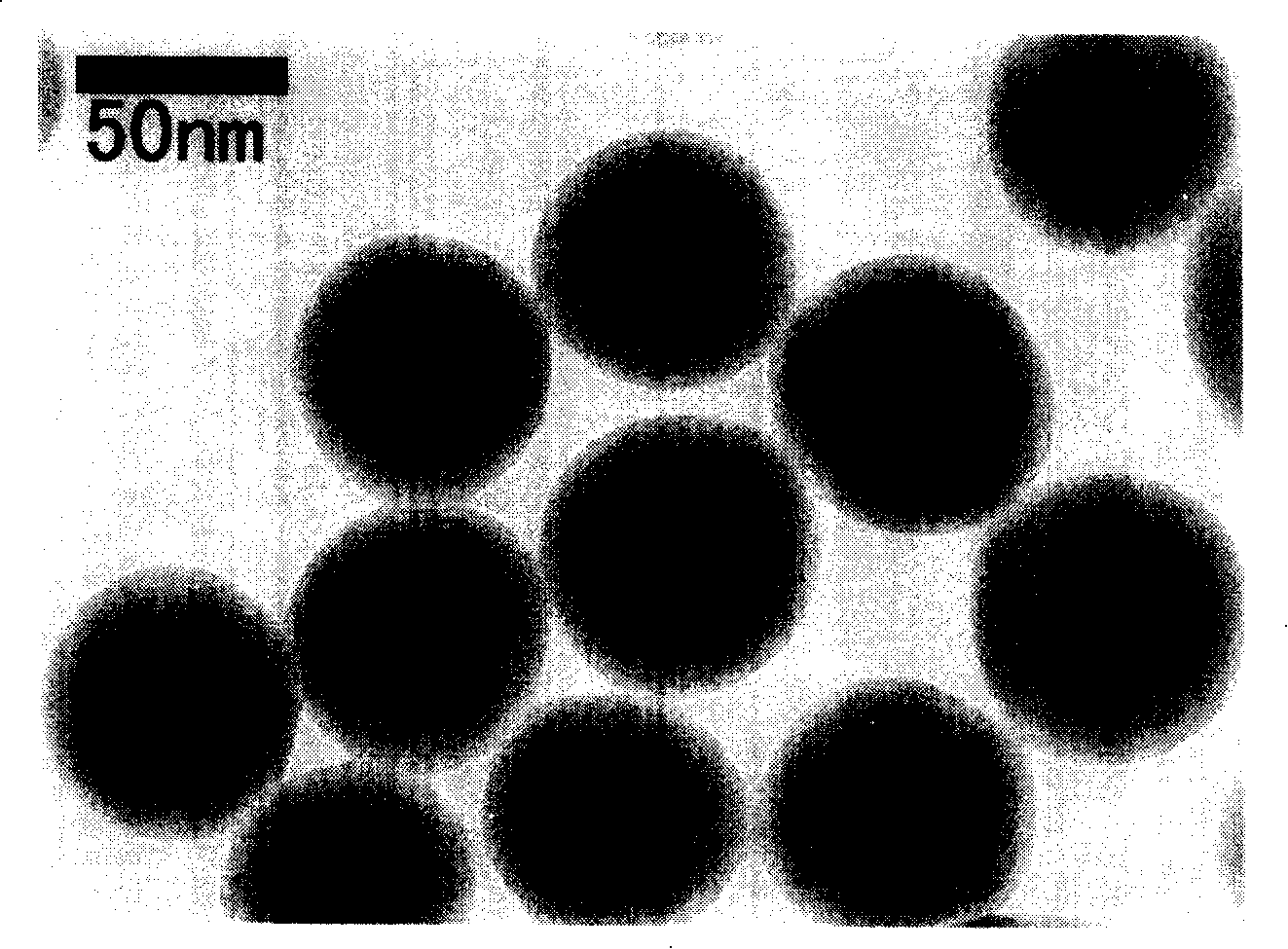

[0045] Preparation of spherical small particles: add 5mL ammonia water and 100mL absolute ethanol into the Erlenmeyer flask at room temperature and stir for 10 minutes, then stir for 2 minutes at 60°C, add 3mL tetraethyl orthosilicate (TEOS) dropwise under stirring, continue at 60°C After stirring for 12 hours, a translucent suspension was obtained, and the resulting SiO with a diameter of about 30-80 nm 2 Transmission electron microscope pictures of small spheric...

Embodiment 2

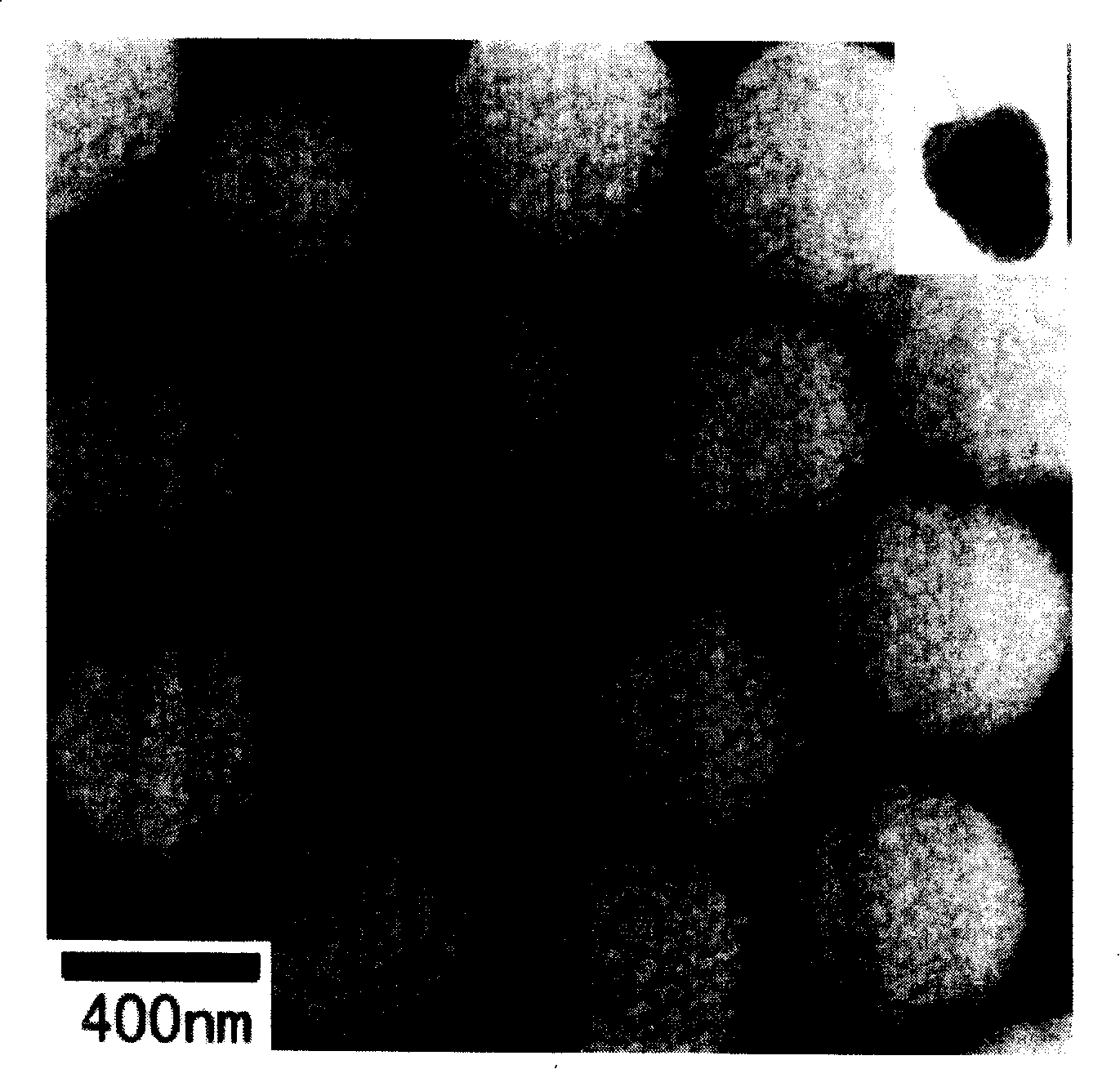

[0047] Assembly of spherical large and small particles: centrifuge the suspension of large particles with a diameter of about 300 to 800 nm prepared in Example 1, ultrasonically wash, and ultrasonically disperse in water to form a suspension with a mass fraction of 0.5% to 1.5%. The suspension was added to an equal volume of PDDA aqueous solution with a concentration of 1-3 mg / mL, magnetically stirred at room temperature for 5-8 hours, and passed through SiO 2 The negative charges on the surface of spherical macroparticles attract the positive charges of PDDA, making PDDA wrapped in SiO 2 On the surface of large spherical particles, centrifuge and ultrasonically wash to remove physically adsorbed polydiallyldimethylammonium chloride;

[0048] Then add the obtained product to an excess concentration of 1-3mg / mL sodium polyvinylbenzenesulfonate (PSS) aqueous solution, so that the surface of the above product is coated with a layer of sodium polystyrenesulfonate, centrifuged, and...

Embodiment 3

[0052] The preparation of super-hydrophilic anti-fog coating: put the ordinary glass flake with newly prepared Pirhana solution (mass concentration is 98% H 2 SO 4 with a mass concentration of 30% H 2 o 2According to the mixed liquid with a volume ratio of 7:3), the treated glass sheet was washed with distilled water, dried with nitrogen, immersed in a PDDA solution with a concentration of 1-3 mg / mL for 5 minutes, and then taken out, deposited on the glass surface Coated with polydiallyldimethylammonium chloride, washed with distilled water to remove physically adsorbed PDDA, dried with nitrogen, then immersed in PSS solution with a concentration of 1-3 mg / mL for 5 minutes, taken out, and washed with distilled water , blown dry with nitrogen, deposited on the polydiallyl dimethyl ammonium chloride coating with sodium polyvinyl benzene sulfonate coating, repeated the process steps of the above deposition 10 times, and finally deposited a layer of polydiallyl Base dimethyl am...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com