Method for preparing asiatic centella total saponins by using macroporous adsorption resin

A technology of centella asiatica total saponins and pore adsorption, which is applied to the preparation of steroids, chemical instruments and methods, and medical preparations containing active ingredients, etc., and can solve the problem of low product recovery and content and adsorption of centella asiatica total saponins Small quantity, environmental pollution and other problems, to achieve the effect of high product recovery rate and content, conducive to large-scale production and application, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

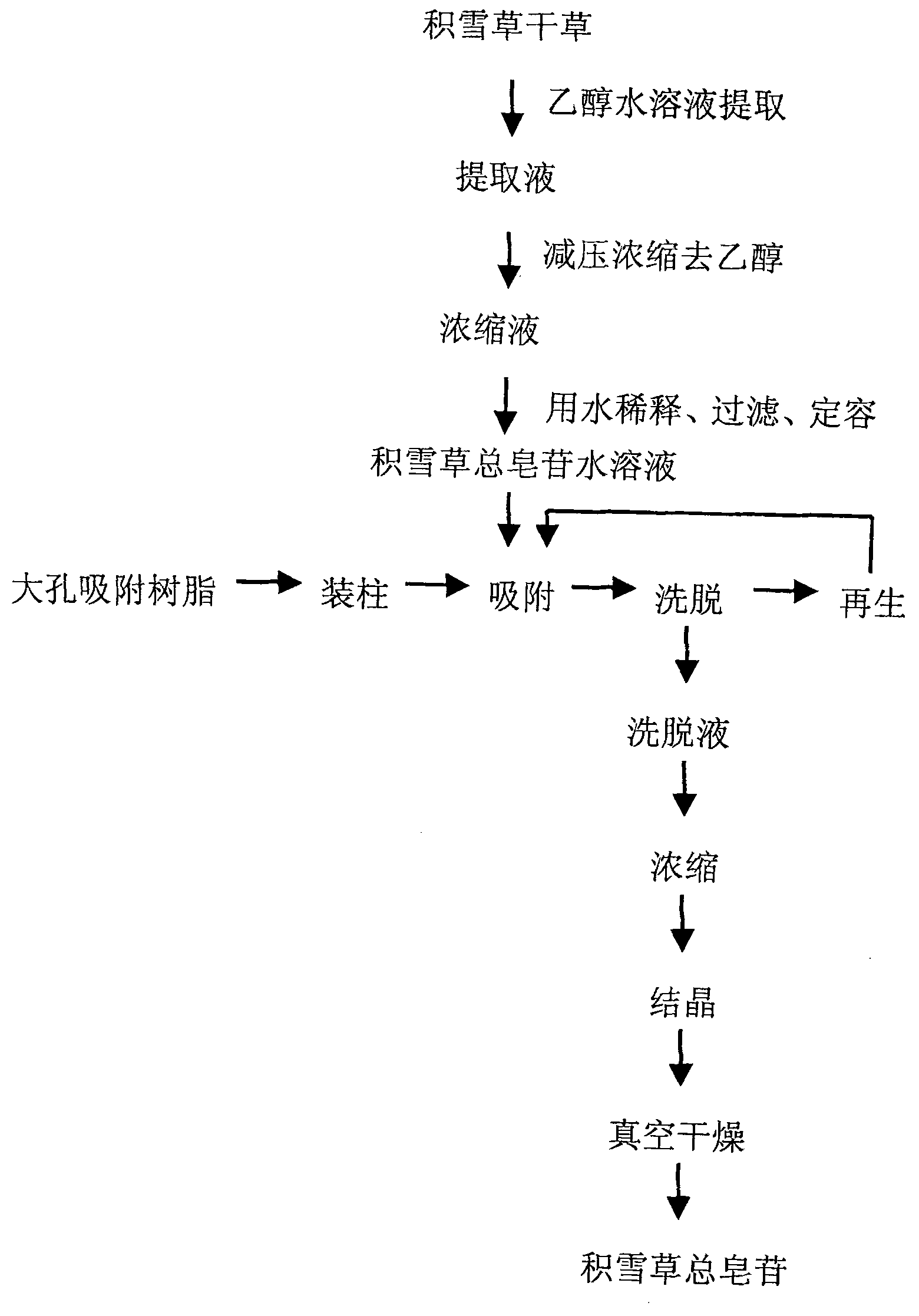

Method used

Image

Examples

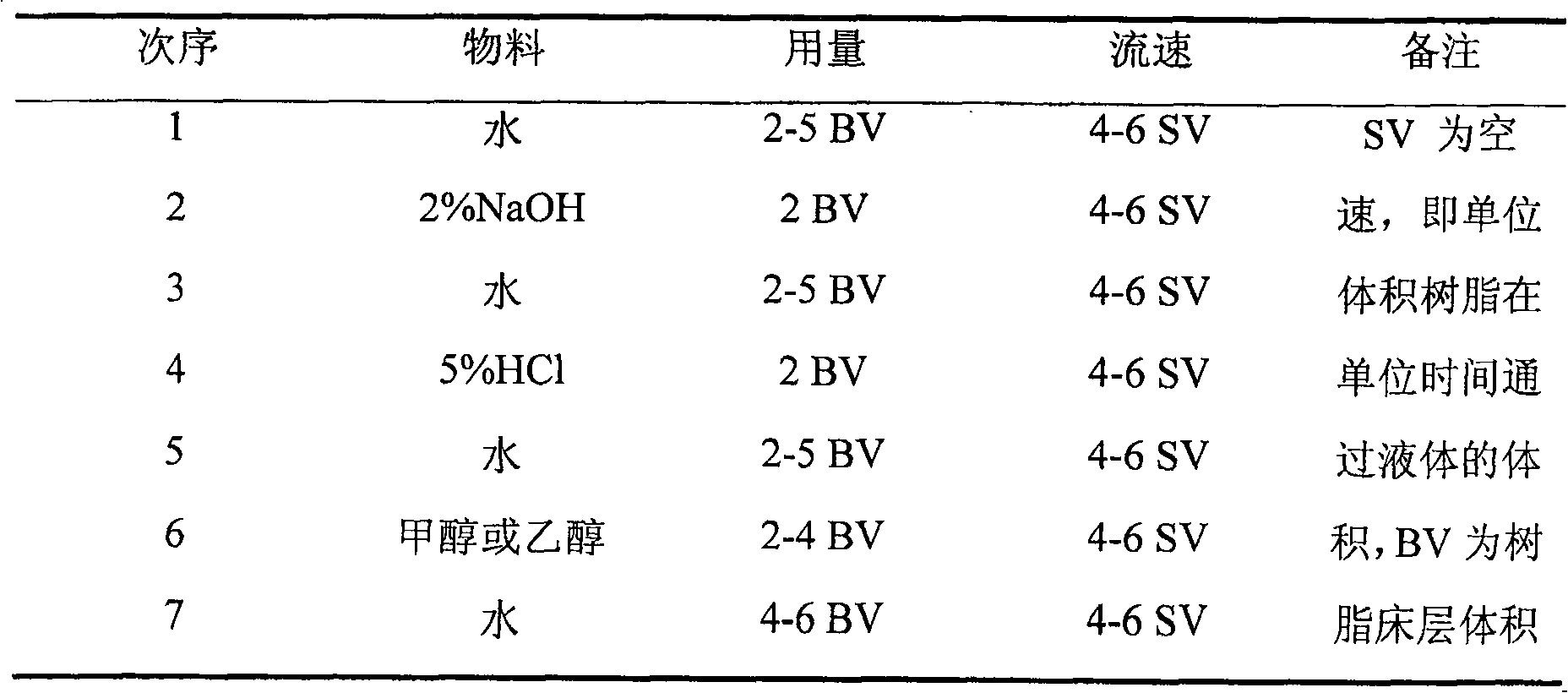

Embodiment 1

[0032] Take 500g of Centella asiatica hay, add 7000g, 4000g, 4000g of ethanol aqueous solution to soak and extract three times respectively, wherein the volume percentage of ethanol in the ethanol aqueous solution is 70%, the extracts are combined, concentrated under reduced pressure to remove ethanol, and 4.8L of concentrated solution is obtained. After diluting with water, filter, and after constant volume, 8 L of centella asiatica total saponins aqueous solution was obtained, and the content of centella asiatica total saponins was detected to be 2.2 g / L; a chromatographic column with an inner diameter of 4 cm was loaded with pretreated macroporous adsorption resin HPD100, the resin column height is 32cm (height-diameter ratio is 8), and the bed volume of resin column is 402mL; Add concentrated solution 7600mL; first wash the resin column with 2 bed volumes of water, then use the ethanol-water mixed mobile phase to elute the total saponins of Centella asiatica at a flow rate ...

Embodiment 2

[0034]Take 500g of Centella asiatica hay, add 6000g, 5000g, 4000g of ethanol aqueous solution to soak and extract three times respectively, wherein the volume percentage of ethanol in the ethanol aqueous solution is 90%, the extracts are combined, concentrated under reduced pressure to remove ethanol, and 1.7L of concentrated solution is obtained. After diluting with water, filter, and after constant volume, 8L of centella asiatica total saponins aqueous solution was obtained, and the content of centella asiatica total saponins was detected to be 1.3g / L; pretreated macroporous adsorption resin was loaded into a chromatographic column with an inner diameter of 5cm HPD200, the height of the resin column is 25cm (height-diameter ratio is 5), and the bed volume of the resin column is 490mL; Concentrate solution 7400mL; wash the resin column with 8 bed volumes of water first, then use the methanol-water mixed mobile phase to elute the total saponins of Centella asiatica at a flow ra...

Embodiment 3

[0036] Take 500g of Centella asiatica hay, add 7000g, 5000g, 3000g of ethanol aqueous solution to soak and extract three times respectively, wherein the volume percentage of ethanol in the ethanol aqueous solution is 80%, the extracts are combined, concentrated under reduced pressure to remove ethanol, and 6.5L of concentrated solution is obtained. After diluting with water, filter, and after constant volume, 8 L of centella asiatica total saponins aqueous solution was obtained, and the content of centella asiatica total saponins was detected to be 1.6 g / L; a chromatographic column with an inner diameter of 4 cm was loaded with pretreated macroporous adsorption resin HPD300, the resin column height is 36cm (height-diameter ratio is 9), and the bed volume of resin column is 452mL; Add concentrated solution 6800mL; first wash the resin column with 3 bed volumes of water, then use the ethanol-water mixed mobile phase to elute the total saponins of Centella asiatica at a flow rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com