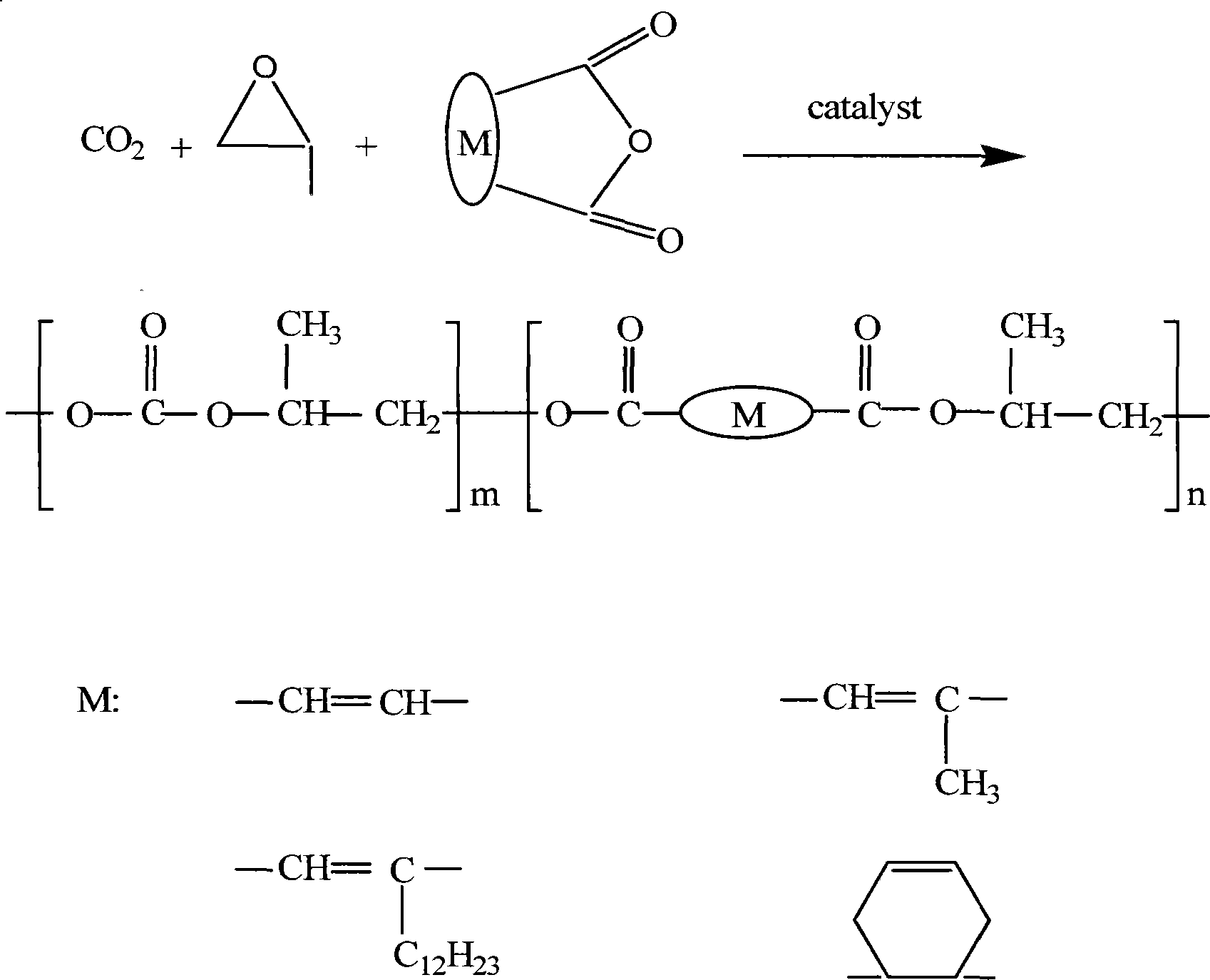

Cross-lined polymethyl ethylene carbonate polymer electrolyte membrane and preparation method thereof

A polymethylethylene carbonate terpolymer and polymethylethylene carbonate technology are applied in the field of polymer electrolytes and can solve the problems of poor solubility, poor mechanical and thermal properties, low ionic conductivity and the like, Achieve the effect of improved thermal performance, easy implementation, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preparation of polymethylethylene carbonate terpolymer: Add 1.0 g of supported catalyst zinc dicarboxylate to a 0.5 L autoclave, connect the reactor to a vacuum system, and then dry the added catalyst under vacuum at 80°C After drying, cool to room temperature, add propylene oxide and cyclic acid anhydride into the autoclave, and pass carbon dioxide, heat, start stirring, adjust the pressure of carbon dioxide to 4.0-6.0MPa, and the reaction temperature is 50-70°C , the reaction time is 10~72 hours, finishes reaction, cools reactor, releases carbon dioxide, takes out the viscous polymer in the reactor, gained polymer is dissolved in chloroform, removes the catalyst in the system with 5% dilute hydrochloric acid solution, And washed with distilled water, the chloroform solution of the obtained copolymer was concentrated, and then precipitated with ethanol, and the white product obtained was carbon dioxide, propylene oxide and cyclic acid anhydride terpolymer. After the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com