Molecular sieve catalyst and application on using phenol and peroxid compounding hydroquinone thereof

A technology for hydrogen peroxide and catalysis of phenol, which is applied in the direction of molecular sieve catalyst, oxidation reaction preparation, physical/chemical process catalyst, etc., can solve the problems of high price, backward production process of hydroquinone, and low production capacity, and achieve the preparation method and The effect of simple process, easy large-scale preparation, and easy separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

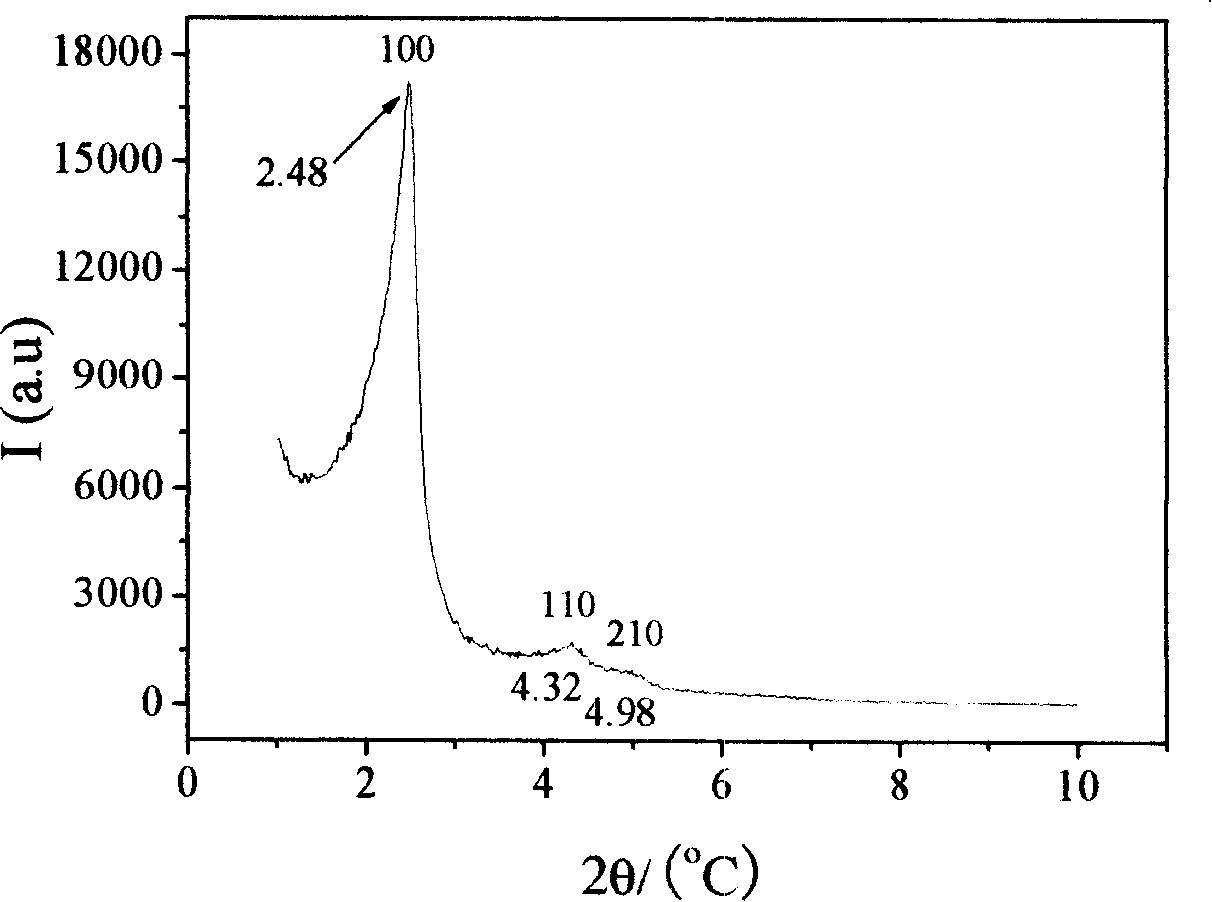

[0029] Embodiment 1: the synthesis of FSM-16 molecular sieve

[0030] Weigh 10.0 g of layered sodium silicate and add it to 100 mL of water, adjust the pH to 7-8 with 2 mol / L HCl, stir at 343 K for 3 h, and then filter. The filter cake was transferred to 200 mL of a 0.1 mol / L aqueous solution of cetyltrimethylammonium bromide, at which point the pH was 10. After stirring for 3 h, adjust the pH to 7-8 with 2 mol / L HCl and then stir for 3 h. Then filter, dry at 393K, and calcined at 973K for 5 hours to remove organic matter.

Embodiment 2

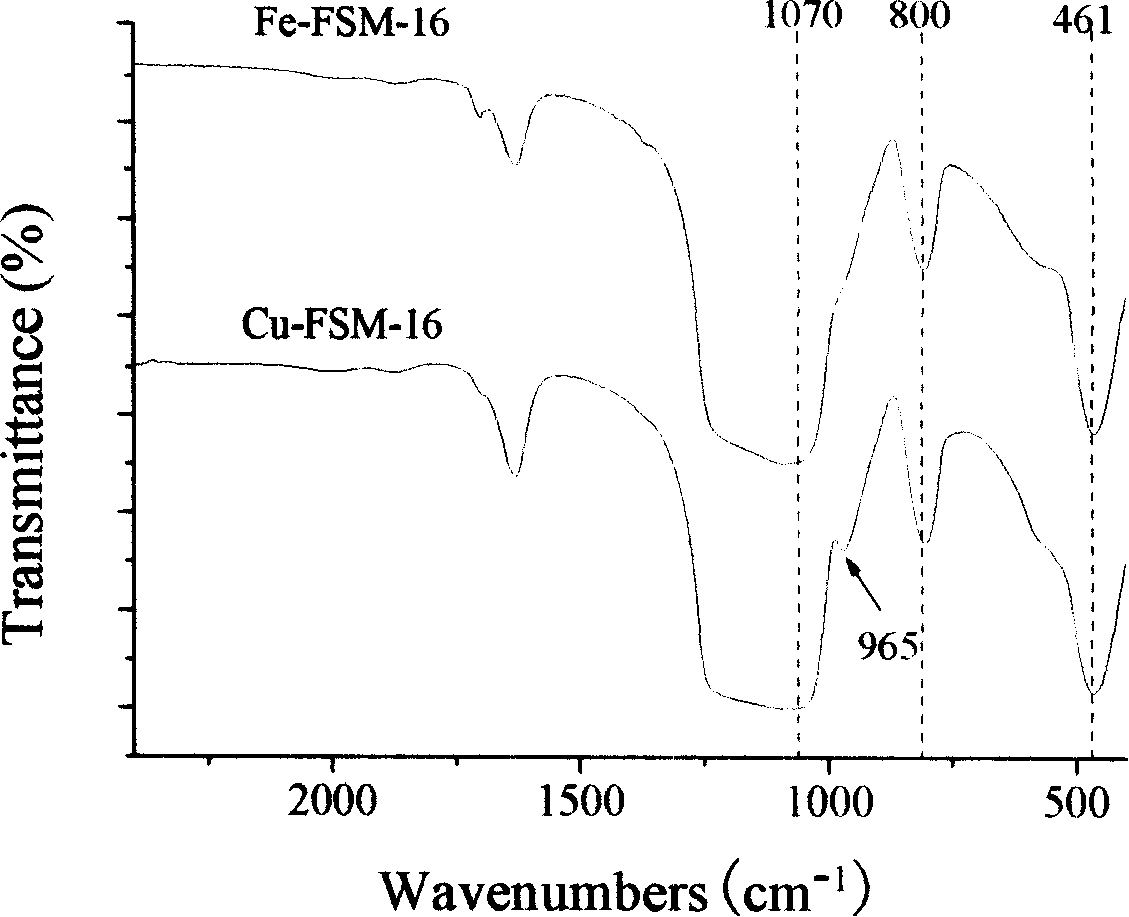

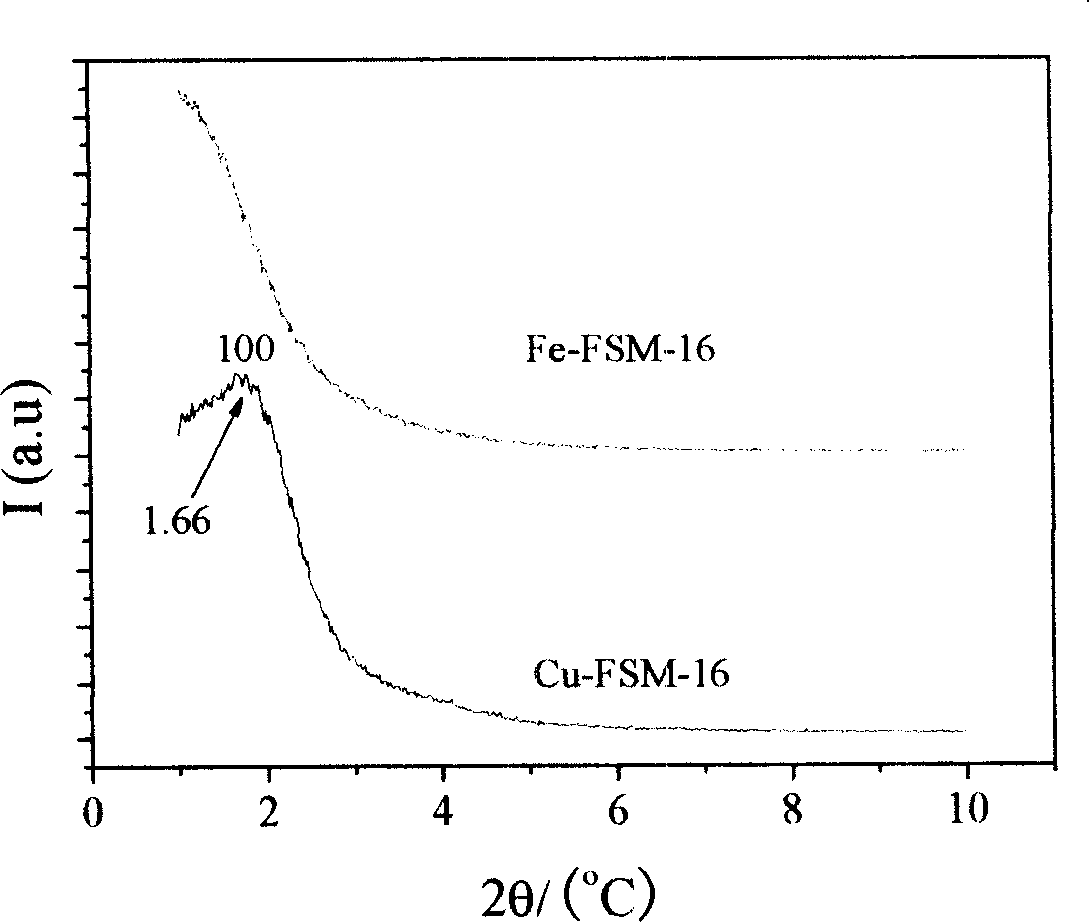

[0031] Embodiment 2: the synthesis of Fe-FSM-16 catalyst

[0032] Weigh 10.0 g of layered sodium silicate and add it to 100 mL of an aqueous solution containing 0.1 mol / L iron salt, adjust the pH to between 7 and 8 with 2 mol / L HCl, stir at 343 K for 3 h, and then filter. The filter cake was transferred to 200 mL of a 0.1 mol / L aqueous solution of cetyltrimethylammonium bromide, at which point the pH was 10. After stirring for 3 h, adjust the pH to 7-8 with 2 mol / L HCl and then stir for 3 h. Then filter, dry at 393K, and calcined at 973K for 5 hours to remove organic matter.

Embodiment 3

[0033] Embodiment 3: the synthesis of Cu-FSM-16 catalyst

[0034] Under the exact same conditions as in Example 2, the iron salt was changed to copper salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com